Oil Lessons with Professor Yanco

Hello!

Today I want to talk a little bit about my passion for oil, I graduated as a Technician in Petroleum Technology about 10 years ago and Im currently working as a Coordinator of the Fixed Base of Logistics Ayacucho 1 of PDVSA, when I was in the university one of my final projects was about The Drilling Fluids a subject that I consider quite interesting so today I will talk about it a little bit, I hope i make this post understandable for the not oil workers and any suggestions or specific topic that you want me to explain let me know in the comments.

we begin then:

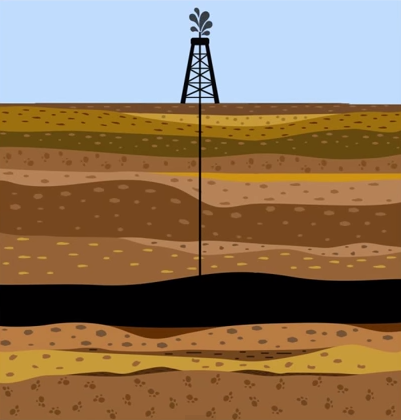

The drilling of wells is an activity that has been practiced in many countries of the world since ancient times, its primary purpose was to obtain brine and fresh water long before the establishment of the oil industry; since oil began to be exploited, drilling has always been an element of great importance; throughout history its technique has varied markedly improving more and more production rates and profits.

The oil is deep, generally at 3000 or 4000 meters, although there are wells of 5000 or 6000 meters deep. According to the projected depth of the well, the formations that will be traversed and the conditions of the subsoil, the most suitable drilling equipment is selected.

The drilling fluid is a liquid or gas that circulates through the drill string up to the auger and returns to the surface through the annulus. It includes all those formulations that are used in the construction phases of a well and, among other functions, is responsible for moving to the surface cuts of the formations traversed by the wick to the formation of interest.

When the main component is liquid, the term "mud" is used to define a suspension of chemical additives (solids and liquids) in the liquid.

Given the complexity of drilling fluid systems, new technologies have been developed in recent times that allow continuous evaluation of the operation of the mud as the drilling progresses. By tracking the main properties of the fluid, the problems of dragging, torsion, pit instability, pipe jamming, incompatible with production formation, among other drawbacks, can be minimized.

The fluid should minimize the following side effects:

- Damage to training.

- Corrosion of the drill string and the coating.

- Piston suction pressures and circulation pressure.

- Loss of circulation.

- Clogging of the drill string.

- Erosion of the walls of the well.

- Retention of undesirable solids.

- Wear of the pumps.

- Contamination of cement slurries.

- Pollution of the environment.

- Reduction of the penetration rate.

A water-based fluid is one whose continuous phase is water, where all chemical additives (dispersed phase) are suspended. Water-based fluid systems are classified by the resistance to the types of pollutants in the formation and their temperatures, which are transformed into their formulation due to the incorporation of flows such as gases, salt, clays, gypsum, liquids and solids. of the formation or chemical additives exceeded and degraded.

In the work that you do with respect to these fluids, we find as conclusions that when using them in drilling:

Ø Fluids based on potassium chloride give better results as inhibitors when formulated with polymers.

Ø Fluids based on potassium chloride are used to isolate production formations when drilling vertical wells.

Ø Fluids based on potassium chloride are excellent clay inhibitors because the potassium ion is of low molecular weight and is soluble.

Ø Ionic polymer fluids are the fluids most used in the oil industry due to their high capacity to ionize in water, being excellent candidates for drilling formations with a high content of clays.

Ø The polymers have excellent rheological properties, carry and suspension for this reason are used in the production phase in order to preserve the stability of this area.

Ø The water-based sludge in its dispersed and non-dispersed phases present an economic and sustainable environmental proposal, since they fulfill the function of lubricating the wick, protecting the walls of the hole and not contaminating the existing aquifers.

Ø When working in wells of great depth it is advisable to use dispersed mud as a chemical thinner.

Ø When drilling shallow wells, the undispersed mud can be used in order to effectively reduce the clay solids.

Ø The formate brines since no densifying barite agents are used, there are no well control problems related to barite sedimentation.

Ø The high lubricity and low solids content of formate fluids reduces torsion and drag in horizontal sections from 2,000 ft. To 5,000 ft. And facilitates slippage in directional control.

Ø Drilling fluids with used formates can be reconditioned in the sludge plant using high-speed centrifuges. What allows you to recycle or reuse it to significantly reduce fluid costs.

Ø A well and reservoir performance is obtained, thanks to the prevention of formation damage.

Ø Lignosulfonates / lignites are powerful chemical thinners that impart inhibitory properties to the system.

Ø The conversion to a lignosulfonate fluid is simple and is done to the extent that the conditions of the hole require it.

Ø Under normal drilling conditions, these systems work well at a ratio of two pounds of lignosulfonate per liter of lignite.

Thank you very much for reading me!

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by Yanco from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

This post has received a 0.09 % upvote from @drotto thanks to: @banjo.

This post has received a 8.85% upvote from @msp-bidbot thanks to: @yanco. Delegate SP to this public bot and get paid daily: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP Don't delegate so much that you have less than 50SP left on your account.