Adjusting the valves

The valve is the part used to open, close or adjust the flow when the pressure in the vessel. A thread is a flow of liquid, water, gas, electrons and various other particles.

The valve is the part used to open, close or adjust the flow when the pressure in the vessel. A thread is a flow of liquid, water, gas, electrons and various other particles.

Adjustment

Want to know how to spend it? Because it's important and gives you the chance to save money, as professional repair will be very expensive. Adjusting the valves can settle down and be a good hobby that will help to establish the engine to keep it running smoothly. You don't have to go to the service, and safely do themselves. Adjustment of valves entails the understanding that in one cylinder there are several valves. Need the clearances in the valve mechanism, which occur between the iron parts from heat. Before you begin, you need the engine to cool, and recheck the clearances with flat feeler gauge.

To begin you need to have all the necessary tools.

You will need:

1) Flat feeler gauge or a special device for setting the gap between Cams camshaft and levers.

2) Extra gasket for valve cover (just in case).

3) a Set of different screwdrivers.

4) Set various keys as mechanical and carob.

Work order

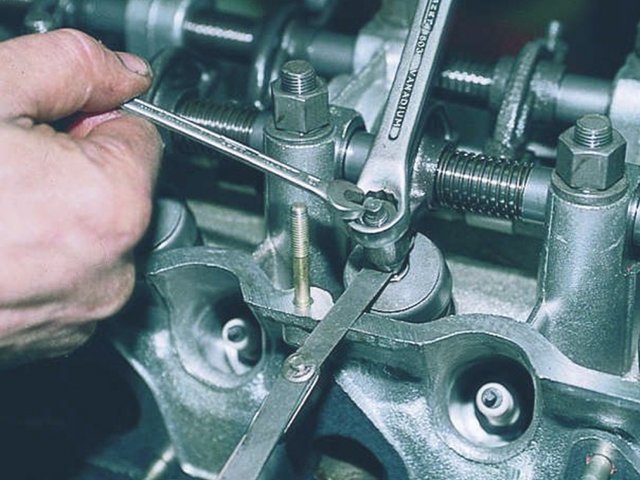

In this process the most important is an accurate procedure for adjusting the valves of the engine. First you need to Unscrew the screws of the unit cover, and then remove it. Don't forget to get the protective cover of the toothed strap. The first thing you should do remove the spark plugs. Drain the oil baths in the head. And then a good look at the surface of the Cams, they should not be damage and other types of wear. The mark on the pulley need to connect with an established tab formed on the rear cover of protection.

That was correct, you need to twist the knee shaft according to the movement of the clock hands, and thus to hold the bolt fixing the pulley to the generator. This location corresponds to the top point of the required cylinders. Suddenly something to screw the knee shaft at forty, fifty degrees, which is referred to as two or three cloves.

Then check the clearances near the first and third Cams. The best if the probe will not go very easily, but not tightly, with a little pinched. Then, turn the knee shaft a half turn forward. Then we will check the gaps in the area of fifth and second. To check the Cams, eight and six, you will need to scroll knee shaft another part of the circle and then to test the fourth, the sixth to scroll through a half-turn. When you start the engine immediately understand whether the operation desired effect. The engine need to listen on different modes. So it can be done.

We hope that our article helped you.