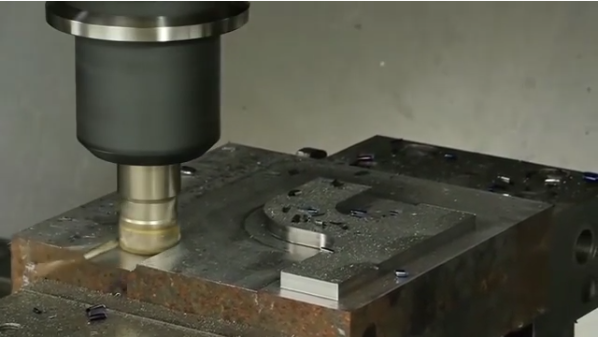

Parameters of cutting speed, feed rate, and cut thickness.

One of the qualities of the metal cutting process is the roughness of the cutting surface.

To make a quality product, of course, must be supported by the good machining process. The roughness of the cut resulting in horizontal milling is strongly influenced by the processes that occur during cutting.

This discussion aims to examine the effect of the cutting process which includes cutting depth, cutting speed and feeding rate, against surface roughness in the metal.

We must know that every machining process has certain characteristics on the surface of the resulting workpiece, one of which is surface roughness. This occurs because in the machining process there is often a deviation caused by cutting conditions and machine stiffness. To overcome this, an experiment was conducted to analyze the effect of cutting conditions such as cut depth, feed rate and cutting speed on surface roughness in the upright fries process by examining the down and rising grinding process.

The nature of the workpiece surface of the machining process consists of two criteria of surface magnification and surface flatness. Between these two elements surface roughness is a trait that can be felt smooth or rough.

In every machining process, the form gurus are generated. The shaping line that occurs has its own characteristics depending on the spearhead of the equipment used. But it all leads to the peak and valley pattern. Line shape

shown perpendicular to the surface is called a curve

rudeness.

On this slice can be seen waves that have a horizontal distance (between the ground and the valley) is longer than vertical (between the peak of the valley). If the focus of sensing is sharpened, it will show the roughness curve.

The process of milling is a machining process whose main factor is the friction between the chisel and the workpiece. During the milling process, there will be several related movements.

This movement can be adjusted based on the parameters of the sling. The parameters studied were cutting speed, feed speed, and cutting thickness.