Exploring the Growth of the Engineering Plastics Market: Trends and Key Drivers

The engineering plastics market has experienced substantial growth in recent years, driven by advancements in materials science, increased demand for lightweight solutions, and a shift towards sustainability. Engineering plastics are high-performance polymers used in a variety of industries, including automotive, aerospace, electronics, and industrial applications. Their ability to withstand extreme conditions, reduce weight, and offer design flexibility has made them the material of choice for many applications.

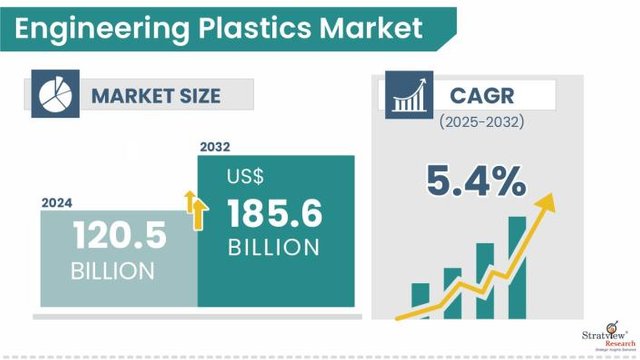

According to Stratview Research, the engineering plastics market was estimated at USD 120.5 billion in 2024 and is likely to grow at a CAGR of 5.4% during 2025-2032 to reach USD 185.6 billion in 2032.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/963/engineering-plastics-market.html#form

Drivers:

• Rising Demand for Lightweight Materials: The automotive and aerospace industries are focusing on reducing weight for fuel efficiency and performance, which has driven the demand for lightweight engineering plastics like polycarbonate, PEEK, and nylon.

• Sustainability Initiatives: There is a growing push towards eco-friendly materials in response to environmental concerns. Engineering plastics that are recyclable and have lower carbon footprints are gaining favor.

• Technological Advancements: Continuous developments in polymer processing and compounding technologies are enhancing the performance and versatility of engineering plastics.

Trends:

• Customization of Plastics for Specific Applications: There is an increasing trend to create custom-engineered solutions for specific industries like medical, automotive, and electronics.

• Growth in Bioplastics: Bio-based engineering plastics are gaining attention as a sustainable alternative to traditional fossil-based plastics.

• Integration with Smart Technologies: Engineering plastics are being integrated with smart technologies, such as sensors and actuators, for advanced functionality in industrial applications.

Challenges:

• High Costs: The production of high-performance engineering plastics can be costly, which limits their adoption in cost-sensitive applications.

• Recycling and Waste Management Issues: While engineering plastics offer many advantages, their recycling and disposal remain challenges due to their complex chemical structures.

• Raw Material Shortages: Fluctuations in the availability of raw materials, such as petrochemical derivatives, can lead to supply chain disruptions.

Opportunities:

• Expansion in Emerging Markets: The growing industrialization of regions such as Asia-Pacific offers new opportunities for the engineering plastics market.

• Sustainability and Green Innovations: Companies that focus on developing bio-based or recyclable engineering plastics have a competitive edge.

• Automotive and Electric Vehicles (EVs): The automotive industry's shift towards electric vehicles (EVs) is a major opportunity for engineering plastics, which are essential for lightweighting and battery housing.

Conclusion:

The engineering plastics market is poised for steady growth due to demand across several high-performance applications. However, addressing sustainability, cost issues, and recycling will be key to ensuring long-term growth and acceptance of these materials.