Steam Power Generation: Fundamentals and the Theoretical Model

Hello Steemians!

Its weekend again and I hope the week was good. For me, let me simply say – I am grateful to God.

Today, I will be discussing another exciting engineering topic with you. It’s going to be all about electric power generation using steam.

There is no need to debate the importance of power in the world today as it cuts across every aspect of our lives. Although, renewable sources are making waves daily and improvement in this area is really advancing it may interest you to know that steam power generation still remains the largest source of power in the world as of today.

In this article I will give an overview of topic and we will discuss the Steam plant theoretical model thereafter and in the course of that I will be pointing out the major components involved.

Without wasting time, let me delve into the discussion proper.

INTRODUCTION

Basic Ingredients

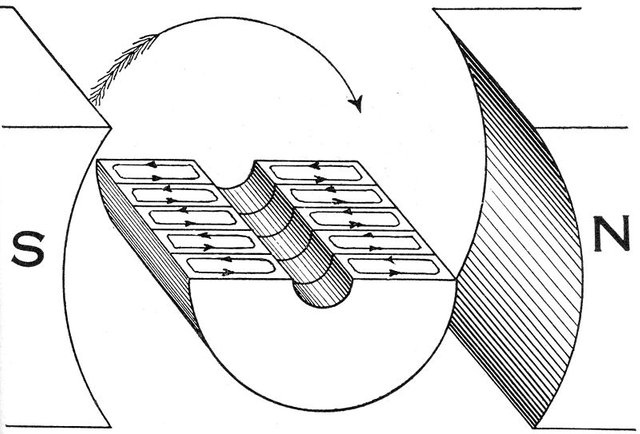

Electricity in steam power plants is directly produced by electrical machines called the Alternators. Perhaps your encounter with an alternator is that in your car. Well you are not wrong - an alternator is an alternator. They all do the same thing which is to convert mechanical energy into electrical energy. They perform this function based on the principle of electromagnetic induction.

Let me explain this principle in a layman’s term. Here we go:

The electromagnetic induction is made possible by three parameters – Current (or emf), Magnetic field and Motion and this is what it says: Given motion and a magnetic field, current will be produced.

The alternator has series of copper coils ready to collect this current. These coils of copper are called the Armature. The alternator also has provision for the magnetic field which could be a permanent magnet or an electromagnet, the latter is usually employed in large alternators as in this case.

Now you know the missing ingredient – Motion (which is a form of Mechanical energy)

How do we generate this mechanical energy?

We all know energy comes in different forms – mechanical, electrical, solar, wind, chemical, thermal just to mention a few. Some form of energy are readily available while some are produced by conversion from another form of energy.

Mechanical energy remains one form of energy that is harnessed by man for a wide range of application, power generation being one of such. However, usually mechanical energy is not readily available and to produce it, we need to convert an available form of energy into this required form of mechanical energy by putting in place an appropriate system.

I could remember as a child, we do play with some mini-fans which we blow air against the blades in order to make the fan blades rotate. This trivia event as a kid is an energy conversion process. Wind from the mouth is directed to these blades to produce a mechanical rotation – wind energy to mechanical energy conversion.

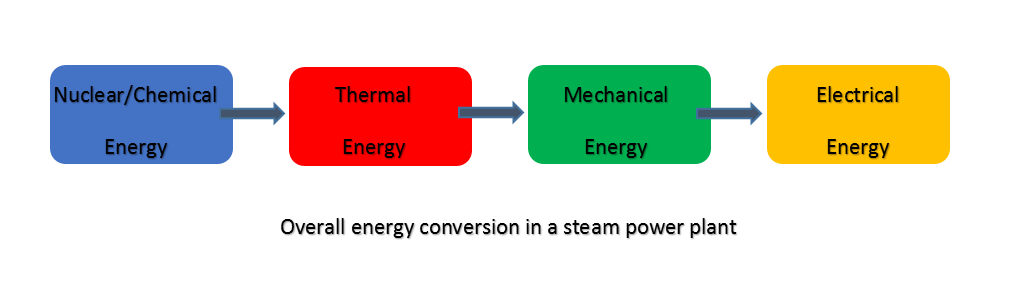

In a steam plant, the production of mechanical energy is achieved by a series of energy conversion process. The sequence is: Nuclear or Chemical energy – Thermal Energy – Mechanical Energy.

The nuclear energy could be derived from the fission of radioisotopes like uranium - 235, or fusion such as that involving Deuterium and Tritium. You can check out this post by @greenrun on how the fission and fusion process works. Chemical energy is derived from the combustion of fossil fuels such as Natural gas, Fuel oils, Coal, etc. The result of expending either the nuclear energy or chemical energy is the production of heat.

The heat derived is then used to boil water to produce steam. The steam is then channeled into the turbine where it does work on the turbine blades to produce mechanical energy in the form of rotation of the turbine shaft.

Now that we have the missing ingredient, what next?

Remember that from the principle of electromagnetic induction, whenever there’s Motion and Magnetic field, current will be induced in whatever conductor put in place and thus electricity is generated. Hence, nothing more is needed. The overall energy conversion process is now represented in the image above.

But how do we make the process continuous?

What I am saying here is that we need a system that will keep producing this mechanical energy, so as to have a continuous supply of electricity. But what system could this be?

Steam power plants are modeled on a thermodynamic cycle which helps in the continuous conversion of heat to work. This cycle is known is the Rankine Cycle and it is the system I am talking about.

Let’s discuss this model in details.

RANKINE CYCLE

.png)

Like every other thermodynamic process, the steam power plant is modeled on a theoretical cycle – The Rankine cycle.

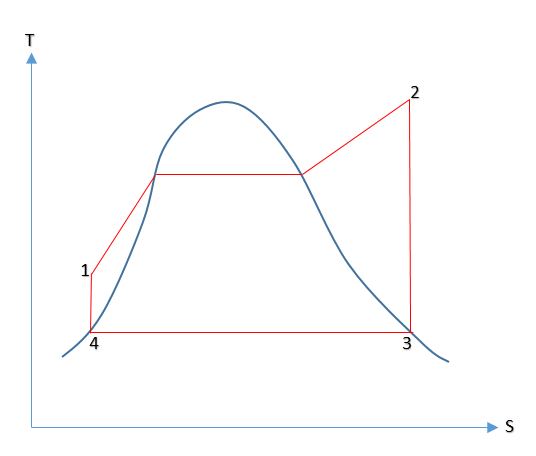

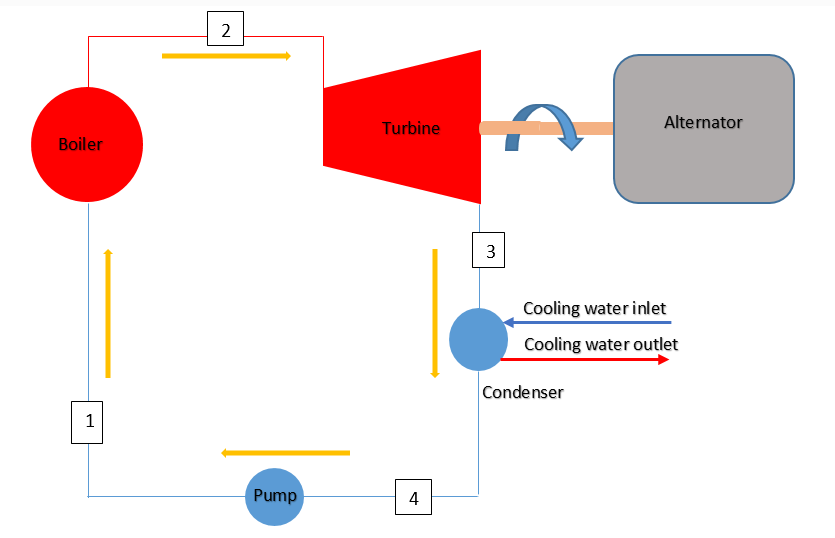

Let’s have this cycle represented on a Temperature – Entropy diagram as shown in the image to the right. Please pay attention to the process diagram just below throughout this discussion of the processes that makes up the rankine cycle. It is a more practical illustration.

.png)

- Process 1 – 2: Constant Pressure Heat Addition in the Boiler

Looking at the process diagram above, you will see that process 1 – 2 encompasses the boiler. In other words, this process takes place in the boiler and it is the boiling of water to steam. Here heat is added to water at constant pressure until the water becomes steam. This steam is usually superheated. Superheating becomes necessary to prevent the steam from condensing easily in the turbine.

Wondering what will happen if the steam condenses in the turbine? Well if that happens, it means we would have water in the turbine which will lead to corrosion. The fact that we are dealing with high temperature and pressure will even aggravate the corrosion process. You can check out my articles on corrosion here and here.

The boiler is simply a heat exchanger where the heat utilized for turning water into steam is derived from a nuclear reaction in a nuclear reactor or from the combustion of fossil fuel in a furnace. Boilers are also called steam generators for obvious reasons.

Now that we have generated steam, what next?

- Process 2 – 3: Isentropic Expansion in the Turbine

It is worthy of note that the whole steam plant processes are all put together for this particular process. It is here we derive the mechanical energy (rotation) that is used to drive the Alternator. The process begins at state 2, where steam enters into the turbine and thereafter impinges on the turbine blades.

In the process of impinging the turbine blades work is done by the steam. Consequently, the steam losses temperature and its pressure drops as well. This process occurs at constant entropy and the volume of the steam increases i.e. isentropic expansion

Since the turbine blades are connected to the turbine shaft, the impingement of the steam on these blades causes their movement and they in turn induce rotational motion in the turbine shaft. It is noteworthy that the Alternator and the turbine shares the same shaft and as a result of this, the Alternator begins to rotate as the turbine commences rotation.

In the alternator, the rotating shaft carries the Armature windings (a set of copper coils) and by the interaction of the rotating armature with the stationary field windings, emf is produced. At this point we have achieved the generation of power.

Now, let me point out an interesting fact to you. If you look at the process diagram, the turbine is represented by a shape starting narrow at the inlet and becoming large as we progress along the turbine axis. This is done to denote that the process going on in the turbine is an expansion process.

Perhaps you might be wondering why state 2 represents the exit of the boiler and at the same time inlet of the turbine as shown in the temperature-entropy diagram.

What you should know here is that the indications on the temperature–entropy diagram is are idealized situations. In reality, the exit of the boiler is not the inlet of the turbine. There are pipings between them. This piping system between the boiler and the turbine is to transport the steam generated in the boiler to the turbine.

- Process 3 – 4: Constant Pressure Heat Rejection in the Condenser

Having done work already, and gotten the power we require from process 2 – 3, why don’t we then discard the remaining processes? Well, we cannot do that, otherwise we would need to boil fresh water again to keep up. This would be wasteful and completely inefficient and there will be no cycle.

Having said this we have to transport the steam to the boiler for another energy input. However, steam is not easily pumped, so instead we turn the steam into liquid form so as to facilitate pumping.

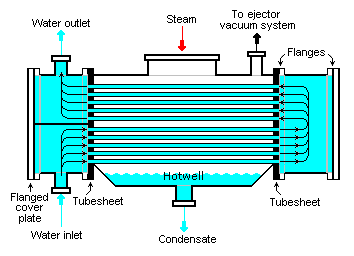

To achieve this, process 3 – 4 is put in place. The steam falls into the condenser, where it losses heat to a cooling water and condenses in the process. The condenser like the boiler is a heat exchanger with tubes inside a big shell. The cooling water are pump through the tubes and the exhaust steam from the turbine falls directly on this cool tubes and exchanges heat with the cooling water - this is how the condensation is acheived.

The cooling water used is usually gotten from a natural body of water. Mostly, steam plants are situated near a large natural body of water for the purpose of condenser cooling. When a natural large body of water is not readily available, cooling towers are used.

For instance, the largest power station in Nigeria, Egbin power plc which is situated in Lagos is a steam power plant and is situated near the Lagos lagoon for the purpose of condenser cooling.

- Process 4 – 1: Isentropic Compression (Pumping) of the Condensate by Feedpump

Remember from the last process we do not have steam anymore, instead we have condensate (or you can called it feedwater). Now we need to return the feedwater to the boiler to regenerate steam. This is achieved by this process. Consequently, the feedwater pressure is raised to the boiler pressure at the end of the process which is state 1.

Finally, the feedwater is back in the boiler and ready to be turn into steam again to begin another cycle.

THERMAL EFFICIENCY

That we have achieved our goal doesn’t mean it is all done. We need to ask ourselves some questions. One of such question goes thus – Is the whole process worth it? Are we getting enough power to justify it? Simply put that, is the process efficient?

In any energy conversion system there always occur losses due to some inevitable event like friction. Having said this, we want to know what proportion of our input is returned.

To achieve this, we need to quantify the input and the output and then compare. In the Rankine cycle, our input is the heat supplied to feedwater in the boiler to convert water into steam. The output on the other hand is the net work done – work derived in the turbine minus work required to drive the pumps to return the feedwater into the boiler.

Thus the efficiency of Rankine cycle is given by

Rankine Efficiency = (Net work done/Heat addition in the boiler) x 100%

With the above expression, we can compute the efficiency of Rankine cycle.

CONCLUSION

As it stands today steam power generation is responsible for the largest portion of the world’s electricity generation. Its operation is based on the Thermodynamic cycle known as the Rankine cycle and the processes in this cycle are performed by four important components which are: Boiler, Turbine, Condenser and Feedwater Pump.

Thanks for reading through.

REFERENCES

Everett B. W., Herbert, B. L., and Thomas, F. L. Steam Plant Operation, 8th Edition. Published. New York : McGraw-Hill, 2005.

Çengel, Y. A and Boles, M. A. Thermodynamics: An Engineering Approach, 5th edition. McGraw-Hill, 2006.

Rajput, R. K. Engineering Thermodynamics. Third Edition (SI Units Version). Laxmi Publications, 2007.

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

.png)

https://www.youtube.com/paulbegley34

Power generation is of paramount importance in developing countries like ours. We have to continue to look for ways of cheap power generation.

I'm quite sure the cost of implementation of steam power generation is on the high side. Not to ridicule your post, you have done a fantastic job walking us through the process of steam power generation.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

Steam power generation is one of the most used form of power generation in Nigeria after hydro.

I loved the way you explained the rankine cycle. This is brilliant.. Keep it up.

Thanks for taking time to read through.

I hope you didn't mistake the spelling of steam for steem??..

I did that quite a lot in one of my posts. I had to correct over and over again😂

Lol... Considering how much this platform as change our lives, one wouldn't be blamed for such blunder.

I am telling you 😂😂

Awesome contribution!

Another post reminding us of the ever expanding field of power generation. The search just continues!

Steam power generation is however established and contributes greatly to the power generation in Nigeria. Thanks so the simple write-up, I picked few more points from here

I am glad you learnt a few things.

Mr. Egbin!

Steam (or steem) power generation still finds relevance in our world today and you explained the concept and processes so well.

Well done!

Mr. Auto!

😀😀

Thanks for taking time to go through the article.

Well I never knew Thermodynamic cycle Is also known as the Rankine cycle

No @mhizkemmie. You misunderstood that part. Rankine cycle is just one of many thermodynamic cycles.

Okay, thanks

you are welcome.

Resteemed your article. This article was resteemed because you are part of the New Steemians project. You can learn more about it here: https://steemit.com/introduceyourself/@gaman/new-steemians-project-launch

@gaman is on the @abusereports blacklist for being a bad Steemian! Bad spammer, bad!