How well do you know about Electrical Machines?

We live in a world where everything has seem very convenient, the advancement in technology has brought about living a happy and comfortable life. The contribution of electrical machines with no doubt has been a major part of this development. The availability of power all time making night seem like day, to the increment in productivity from manufacturing industries, sitting right there on that couch in your living room with the cool breeze from your fans and many other forms of convenience you may think of comes as a result of these machines. The world indeed has revolutionized with the development of electrical Machines.

The machines I'm talking about here are ones which you could easily think of but you may not have taken it's significance with some remarkable worth. They are very important to life's productivity as this is why I think I should share a few things on these machines.

Electrical machines are machines that uses electrical and magnetic forces for their operation, they make use of these forces for energy conversion, so you can simply regard them as energy converters.

Image Credit: Pixabay

TRANSFORMER

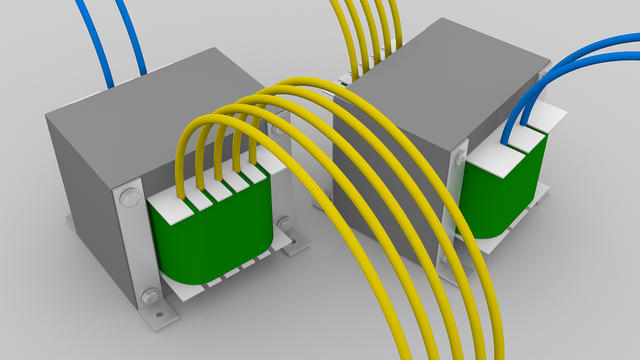

The first electrical machine I'd be talking about is the Transformer. Transformers basically is a device in which electric power is transformed from one circuit to another. A Transformer is a stationary device used in raising or lowering the level of voltage in a circuit. The Application of transformer is found from a very little appliance to large appliances.

Transformer.[CC0] , from Pixabay

Transformer.[CC0] , from Pixabay Transformer basically are made up of two coils; the primary and secondary, linked together magnetically. As small as a transformer could take a form to a largely made transformer, they all work on the same principle. This principle is such that if an alternating current AC source is fed into the primary coil of the of a transformer, an electromotive force (emf) is induced in the secondary coil by setting up of alternating flux within the magnetic core.

Let's take a quick look at the construction of a typical Transformers.

A transformer in it's simple form consists of two coils which forms the primary and the secondary winding which are separated by laminated steel core. The laminated core serves as a path for magnetic flux which are made to produce high permeability and minimize loss. The core is so laminated to minimise energy loss to the minimum.

The construction of Transformers can generally be of two types differing in the manner in which the primary and the secondary coil winding are placed around the laminated core. The first type is the core type which has its winding surrounding the coil i.e. the windings are wound outside surrounding the core ring while shell type have the core surrounding the windings i.e the primary and secondary windings pass inside the core, forming a shell around the windings.

However, we have transformers which are of just a single winding, serving as both primary and secondary sides. They are the Autotransformers with just one winding but provided with various tap positions to get different level of voltage thereby acting as a step up or step down transformer. They are mostly found in use as power transformers.

From this little explanation, transformers can be considered as a step up or step down transformer. A transformer having it's secondary winding much higher than the primary is regarded as a step up transformer while one having the primary winding much higher than the secondary is regarded as a step down transformer.

The ability of a transformer to transform voltage levels around makes it a very unique equipment in the world of engineering. Small transformers are found in appliances such as charger adapters functioning as step down transformers to get a lower desirable voltage for low rated appliances.

The use of transformers are as well found at higher level applications for power transmission and distribution. Transformers found at high level application are referred to as Power transformers. They work with the same basic principle of magnetic induction, the are high rated transformers ranging from 50KVA to as much as 300MVA.

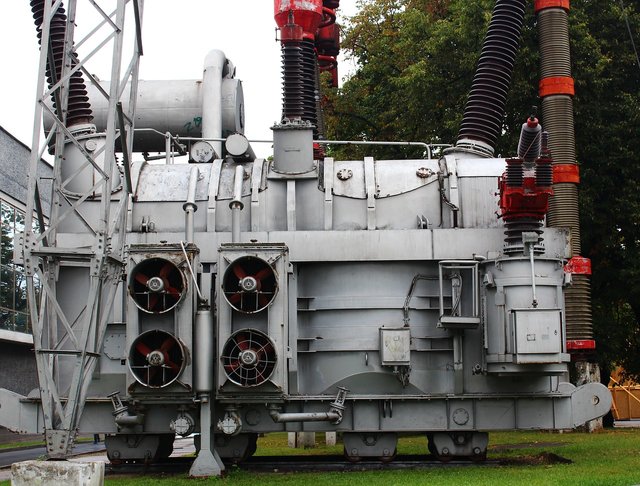

POWER TRANSFORMER

.jpg) Power Transformer. [CC0] , from Pixabay

Power Transformer. [CC0] , from Pixabay Power transformers are housed in a metal tank tightly sealed containing a special type of oil which cools the transformer during operation and at the same time serves the purpose of insulating the transformer.

The make up of a power transformer comprises various parts which functions to attain high efficiency from the transformer and also provide protection for the transformer.

The fundamental parts of a power transformer include:

• BREATHER: Power transformers are said to be tightly sealed but this is practically impossible. It is then absolutely important to prevent the transformer oil from moisture as it is lowers the dielectric strength of the transformer oil and as well affects the insulation. Therefore breathers are provided on transformers to make sure the air entering the transformer is moisture free. Breathers as the name suggests permits oil in the transformer to expand and contract as the temperature rises and fall. Doing this, the breather which consist of silical gel in a container entraps the moistire, absorbs it, not allowing the moisture to pass on to the oil thereby keeping the transformer oil from atmospheric moisture.

• COOLING FINS: Cooling fins are a form of cooling mechanisms provided on transformers to dissipate the heat generated. This is employed for better performance of the device as heat reduces the transformer efficiency.

• COOLING FANS: As vehicle radiators are always accompanied with cooling fans, so are cooling fans of transformers are also found attached to transformer cooling fins blowing air to the fins for cooling purposes

• HIGH VOLTAGE BUSHING: The high voltage bushing is the termination point for the primary winding of the transformer. For example, a transformer to step down 330KV/132KV will have its high Voltage bushing at the primary side.

• LOW VOLTAGE BUSHING: This is also the point at which the secondary winding of the transformer is being terminated. It's the termination point for the output voltage as the case of the step down transformer described. High and low voltage bushings can easily be distinguished from each other by their sizes and they generally serves the purpose of insulation.

• CONSERVATIVE TANK: This is a small sized tank found above the transformer, it is connected to the main transformer tank. It allows the expansion and contraction of of the transformer oil during temperature variation, conserving the transformer oil.

• DRAIN VALVE: The drain valve is located at the lower part of the transformer tank, where the opening and closing of the tank for oil check or replacement can be done.

• EXPLOSION VENT: The explosion vent is used as an escape route for transformer oil when internal faults occur within the transformer which may lead to an increase in the oil temperature. Instead the transformer getting exploded , the oil is expelled through this vent preventing transformer from exploding. It is placed above the conservator tank.

As much as transformer could give such an amazing features, they come with the setback of energy loss. Transformer losses mostly come in form of heat as a result of alternating magnetic field. This type of losses are regarded to as transformer iron loss.

Another loss found with transformers are ones offered due to electrical resistance of the primary and secondary winding which opposes the magnetising current going through them. This type of loss is regarded as copper loss. These losses found in transformer are determined by voltage and current, making the total transformers loss depend on voltage-Ampere. The reason transformers are mostly rated in KVA and not KW.

However, in order to minimise losses in transformers, the efficiency is improved by bringing the windings within close contact which improves the magnetic coupling and making the transformer core with laminated thin steel.

INSTRUMENT TRANSFORMER

Instrument Transformer. [CC0] , from Pixabay

Instrument Transformer. [CC0] , from Pixabay The application of transformers doesn't just stop with voltage level transformation. There are special type of transformers called the instrument transformers. These types of transformers are specially designed for metering operation providing some form of protection alongside.

Here is what I mean; It is impracticable to measure directly with low range measuring instruments (voltmeter and ammeter), the voltage and current of a power transmission line. Hence, instrument transformers are designed to be used alongside the low rating measuring instruments for the metering of power line voltage and current.

Instrument transformers are employed in this case, they are connected to the high voltage line to step down the voltage or current in a ratio of proportional magitude and the output is fed to the coils of the low range measuring instrument for metering. These instruments transformer are of the current and voltage type, they basically make the low range measuring instrument capable of measuring voltage and current from high voltage lines.

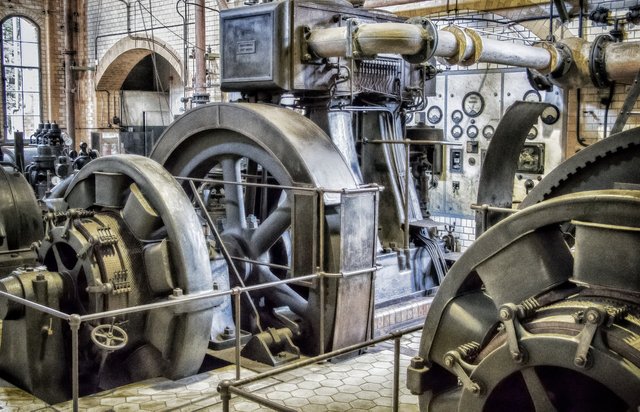

GENERATOR

Generator. [CC0] , from Pixabay

Generator. [CC0] , from Pixabay You call it a generator, Electrical Engineers call it alternator, it is also referred to as a synchronous machine. One of the electrical machines that has brought about revolution in the generation of power. A machine is said to be synchronous when it moves at a speed which delivers voltage at a standard frequency (50Hz or 60Hz), of power system. Hence, we a call a generator a Synchronous Machine

A Synchronous Machine or an alternator is a device capable of producing electrical energy with the principle that whenever flux is cut by a conductor, an electromotive force (emf) is induced in the conductor coils. The principle I'm referring to here belongs to Michael Faraday The concept of Faraday's electromagnetic Induction has made it possible the large production of electricity with the development of powerful alternators.

A Synchronous Machine basically consist of a stationary element (Stator) and the rotating element (rotor). Unlike transformers with no rotating part, synchronous machine have a rotating part which forms the basic principle of its operation. Simply going by the principle of electromagnetic induction, whenever the rotor rotates, the stationary conductors are cut by magnetic flux, thereby they have induced electromotive force (emf) produced in them.

The rotor of a synchronous motor are designed having north and south pole. By these, during operation, they induce electromotive force (emf) in the stator winding which flows in one direction then in the other which result in an alternating emf being produced in the stator conductor, in which the frequency depends on the number of North and South poles moving past the conductor in one second. This basically explains the concept of power generation in alternating current (AC). Maybe that's where alternators found it's name i.e the production of alternating current.

Similarly, we have generator which output is direct current, they are called the dc generators. They work on the same basic principle of electromagnetic induction as of the AC generators but just a reverse in arrangement. In dc generators, the conductor rotates while the field system is stationary. Commutators are used to collect alternating currents and convert into direct current and then brought out by brushes.

This concept has basically explained the principle of generator. Power is generated from generator as either alternating current AC (alternator) or direct current (Dc generator) with energy conversion based on the principle of electromagnetic Induction with essential parts being magnetic field and the conductor.

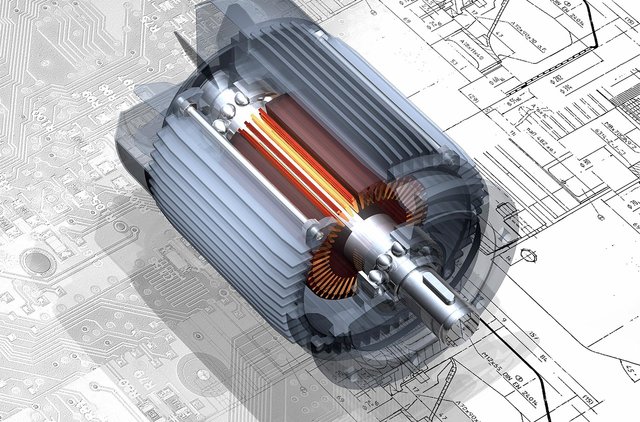

ELECTRIC MOTOR

Electric Motor. [CC0] , from Pixabay

Electric Motor. [CC0] , from Pixabay Electric Motors are also a very important electrical machines. An electric motor basically does the reverse action of generator, converting electrical energy to mechanical energy. As we have it in generators, electric motor can be of AC and DC type as well. They consist of stator coil in which alternating current is supplied, to cause a magnetic field on the rotor. The rotating effect caused in the rotor by induced current are used in many applications.

The electric fan is a simple example of the application an electric motor. The fan is an induction motor in which alternating current is supplied to the stator coils inducing a magnetic field on the rotor coils, thereby giving the fan the rotary motion. Electric Motors are found applicable in almost every aspect of life. They are found applicable both in home and industrial use.

In Summary, Electrical machines are found with diverse applications. They are energy converters which application can be found in almost every aspect of life.

I hope you've been able to get a few things about Electrical machines. I do appreciate your time here. Thanks for stopping-by.

REFERENCES

B. L Theraja & A. K. Theraja [S. Chand]. A Textbook of Electrical Technology

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

I'm a proud member of @promo-mentors where you get mentored and guided on how to make quality posts on steemit amongst other benefits. Do join us on discord. We anticipate your arrival.

Nice and short summary, keep up the good work.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

Reminder articles, I never loved electromechanical courses.

Just had to know them, now I appreciate it more wit thus article

Thanks for the information @olajidekehinde

Nice digging engr Kenny. You have done a pretty good job simplifying these.

Electrical machines have made life much more easier

Kudos to you

Hi @olajidekehinde!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

All thanks to Faraday, we are enjoying the gifts of electromagnetic induction. the applications are seemingly never ending!

Offcourse yes, the application never ends. All Thanks to the Faraday's of this world. Thanks for stopping-by @rharphelle

The use of transformers can not be overemphasised and from a fellow Electrical Engineer: I must say You did a fantastic job with this article @olajidekehinde

Great article. I majorly like the transformer part but why does the major transformer look so big compared to the ones in charger and the likes?