Borehole Drilling

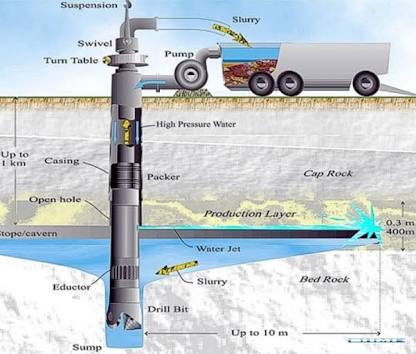

Borehole mining tool and technology principle schematic, source: wikimedia commons

The comprehension design of a borehole involves the selection of appropriate casing size and material; length, diameter and material for the screen; estimation of well depth and size of the screen slot; and choosing the construction of method. The design is usually influenced by the type of drilling rig. A successful pumping borehole requires an experienced hydro-geologist to locate the site, a competent drilling contractor using modern techniques and materials, and correct selection of pump.

A properly designed and contructed borehole has a life span of over 30years. Drilling, casing and screen costs constitute the major part of the total cost of the well. The estimated safe yield of a borehole is limited by the aquifer characteristics.

The diameter of the casing must be large enough to accommodate the pump and to ensure an uphole velocity less than 1.5m/s.

Site Investigation

An essential preliminary aspect of groundwater development and borehole design is site investigation. Site investigation is essential in order to locate the ground water source. High cost of drilling makes it important to ensure the existence of satisfactory aquifer before embarking on full development. The methods used may be classified broadly into surface and subsuface methods. One of the most prominent surface methods is the geographical methods. The geographical methods enable the determination of stratification in soils and rocks by measuring changes in physical characteristics of the material such as magnetism, electrical resistivity and density. Some of the geographical methods are the Electrical resistivity method, seismic method,magnetic method and so on.

The Electrical Resistivity Method

The Electrical method relies on the differences in electrical resistance or conductivity between one soil or rock type and another. An electric current is passed through the ground between a pair of electrodes, and the drop in potential measured by an inner pair of electrodes. Since water increases the conductivity of the soil rock, the presence of groundwater may be indicated by a decrease in resistivity. Hence, if the distribution of the electrical resistance in the subsoil is known, conclusions can be drawn concerning the thickness of and depths to the interfaces of the surfaces layers. For instance, the apparent depths and resistance of a stratified subsoil can be determined by vertical electric sounding (VES).

Although electrical resistivity method has some very useful applications in site investigation for water resources development, it has some disadvantages. Lateral resistivity variations may hinder accurate interpretation of sounding data. Besides, depending on the minimum electrode spacing used, narrow fracture zones might be missed by resistivity profiling. For such narrow productive fracture zones, electromagnetic traversing should give better results.Seismic and Magnetic Method

Under seismic method, a charge of explosives is fired near the ground surface and the time of travel of the resultant shock waves to series of geophones away from the shot point noted. The time of arrival of the waves depends on the nature and depth of the underlying strata which are deduced from a seismometer.

In magnetic method, the intensity of the earth's magnetic field is measured. A special type of an electromagnetic (EM) geophysical equipment is the slingram which was developed by ABEM/Swedish Geological Company. It comprises of a portable transmitter and receiver carried by one person each. The two persons walk along a survey line of 1 to 1.5km per hour, separated by a constant distance of 20 metres by a connecting cable. The distance depends on the depth of overburden and the penetration desired. The transmitter creates a primary electromagnetic (EM) field with frequency of 3.6KHz which in turn induces a secondary field in the ground. This field is then picked up by the receiver and compared with the transmitter 's primary field. The secondary field varies according to the nature of the groundwater and the surrounding rocks. Such variations (called anomalies) are indicated in the instrument readings as curves with different characteristics. Two different readings, real (in phase) and imaginary (out of phase) are made each time. The ground water potentials are located from the knowledge of the shape of the EM profile, position and sizes of minima and maxima, amplitude of minima and maxima and relationship between real and imaginary readings.

This method has proved very successful in UNICEF assisted projects in Kwara and Gongola states of Nigeria with over 90% success rate for over 2000 well sites located as against 60-70% without such surveys. The depth of the overburden surveyed is influenced by the coil spacing, conductivity and thickness of formation, and the frequency of transmitted em field.

Geographical Survey and Interpretation of Aerial Photographs

By examination of the geological features such as joints and fractures water bearing formations can be delineated. The nature and thickness of overlying formations and dip of water bearing strata enable the estimation of the drilling depth.

On the interpretation of aerial photograph, surface features such as vegetation, erosion, drainage patterns and rock types are associated with the occurrence of groundwater. Hence, the aerial photographs of these features and their interpretation can help locate water bearing formations. The subsurface exploration is useful in confirming the actual location and nature of the aquifer. The permeability and yield are obtained from samples of soils and rock obtained with small diameter test holes.

Design

A borehole or well essentially consist of the conduit portion where the pump is installed and a passage is provided for the flow of water to the pumping intake and then intake portion where the groundwater enters the well. A properly designed borehole or well should be able to abstract clean water at a maximum rate that will not facilitate the clogging of the screen and at a minimum cost and frictional loss without polluting the water source. Boreholes are designed based on available data from hydro-geological and geophysical surveys and from the boreholes drilled earlier in the area.Design Steps

The design steps are dependent on the availability of data, method of construction and type of well. The design steps for a borehole are based on the projected population the water demand is determined, the anticipated yield of the well is estimated and compared with the water demand, using the yield from the corresponding nominal size of the pump bowls and the optimum and smallest sizes of the pump bowls and the optimum and smallest sizes of the well casing, estimate the drilling bit for the test /pilot holes, drill the test holes and collect samples at the intervals for sieve analysis for design of the screen slot, determination of the zones of highest conductivity, that is the most productive layers, conduct pumping tests for determination of transmissibility, coefficient of permeability, specific capacity and yield of the aquifer, determine the screen length, check whether the entrance screen velocity is within limits and finally check the coefficient of permeability.

Drilling

Drilling requires the use of a drilling fluid or mud. The drilling fluid is indispensable in drilling operations and except when it is performed through hard rocks where compressed air is used. A drilling fluid is essential to cool the drill bits and lower the friction between the drill tools and the geological formation, thereby facilitating cutting. During drilling operations, the fluid from a tough coating against the borehole walls thereby stabilizing it. The fluid also buoys up loose soil and rock cuttings to the surface during drilling and prevents them from sliding to the bottom of the hole during stoppages. A special drilling fluid normally used is bentonite. This is a swelling clay mainly of montmorillonite, a mineral with strong water absorbing gel-forming characteristics. A suitable mud should have a specific gravity of about 1.16. The rate at which mud is introduced or pumped affects the rate of cutting. As drilling proceeds deeper, high speed of pumping mud is essential to ensure quicker Return Of cutting from such depths. The cut outs are flushed out before changing or adding another drill pipe to avoid blocking the screens.Procedure of Sinking a Borehole

Rig drilling known locally as Borewell for Water well drilling in operation in India, source: wikimedia commons

The procedure for constructiconstruction of a borehole or well depends on its type, depth and technology available for its construction. The general procedure of sinking a borehole is as follows:

The first step to consider is to sink a cased borehole with 200-300mm diameter larger than the inner well casing. A large diameter borehole or well shoLid not be constructed near existing structures to avoid land subsidence. Boreholes should be spaced beyond their radius of influence to avoid interference (that is, a situation where pumping from one borehole influences the quantity of water drawn from the other). The suggested spacing is 600-1000m for alluvial soil and 100-200m for Hard Rock.

The second step is to insert the inner well casing which is provided with a perforated screen where abstraction from the aquifer is required. The screen terminates in a 3-5 length of imperforated pipe to act as sump to collect any fine material which may enter through the screen. The screen may consist of the slotted PVC tube surrounded by filter in the form of a nylon or terylene mechanism sleeve. Slots are preferable to holes to reduce risk of blockage from round stones.

The third step is to place a graded gravel between the inner casing and the out casing over the length of the screen. This step may e omitted if the soil is such that the screen can stand alone.

The fourth step is to withdraw the outer casing in stages as the gravel is placed.

The fith step is to backfill the remaining space above the screen with any available material.

The sixth step is to allow water to surge upward and downward through the screen using a boring tool. This will also help remove unwanted fines in the sump by baler.

And the final step is to install the submersible pump.

General Pumping Consideration and Summary

Pumping rate should never fall to the point of allowing cascading to occur. Cascading water causes entrapment of air which is drawn into the pump suction resulting in undue wear and a reduction in performance. Also, the air oxidizes iron to form ferric hydroxide which chokes the screens, pump and pipe work. The head of water should always be positive even under drawdown conditions so that iron is held in solution. Reduction in groundwater pressure due to pumping causes the release of carbon dioxide and deposition of calcium carbonate.

In summary, boreholes are constructed for different purposes. For example like extraction of water, petroleum liquid and natural gas. Boreholes may be sank by using a drilling rig or a hand-operated rig. The techniques and machineries used to sink a borehole varies from the manufacturer, geological conditions and the intended purpose.

Reference

[1] Borehole mining

[2] Borehole

[3] Borehole water journal online

[4] Borehole encyclopedia

[5] Facts About Water And Water Boreholes

[6] Water borehole drilling process

[7] Borehole design construction and selection

.png)

In my country, a borehole is to be found in nearly a radius of about every 5 kilometers, in at least every village. That popular are boreholes.

This a good detail of borehole drilling, one caveat I thought you might want to make, is that given selected sites must, besides satisfying the condition of being located in topographically favorable areas where there is a wide zone of weathering with deep rock fracturing, must also – and this is very important – meet environmental criteria, ie.e. located away from groundwater pollutants.

But of course that, as you finally indicate, depends on the purpose for which the borehole is being drilled. It wouldn't probably matter much if it is being drilled for agricultural purposes, but if for human consumption like in my country, it matters a great deal.

I have always wondered how life will be like without borehole technology in Nigeria given the almost comatose state of the public water supply agencies.

@greenrun life would be boring I must say. During my National youth Service in northern Nigeria i had water issue. No good source of water. If not the help of UNICEF support water project It would have been horrible. Thanks for your feedback boss!

Water issues are part of my professional research. I'd be very interested to read anything you have to write about that.

que bueno aquí en Venezuela hace mucha falta,éxito, te sigo

gracias por tus comentarios!

A lot of borehole drillers here in Nigeria do not really do the necessary survey before choosing where to drill because i have experienced up to two failed boreholes... Or am i being subject to stereotype?

You are correct. You know most of them lack the basic engineering principles and specifications on borehole drilling, they carry out what is called eye gauge to drill boreholes and the aftermath is failures.

Eye gauge you say(lol). Thats what majority of these local engineers keep doing.. Even when it comes to machining on a lathe. They do eye gauge as well.. And when you ask them they will tell you they aren't new in the game meaning thats not the first time they are doing things like that without precision or the ideal steps which is prone to error in a short while most often ..

Thanks for this eye opening bole hole drilling system. Great job

Yup! So bad of the quack engineers.

Would be nice if you had given us examples of 'when things go wrong'! Maybe illustrate each section by a historical case where it went bad.

yeah. You can check my blog on Borehole failure. I wrote an article on it.

Wow, how come i didnt see this post until now.

Are you a geophysicst?

Cos that is what i'm currently studing, and in my course for this semester, im taking AGP 401- Borehole Geophysics. And i find this helpful, i understand the course a lot more now.

Thank you so very much

you are welcome!

I'm Soil and Water Conservation Engineer. My field is related to Geophysics.