DRYING AS A BACKBONE OF AGRICULTURAL STORAGE : Why and How it has to be done

If you're reading this, it means you're still alive and that will mean you're breathing dry air. Unlike many things that are overrated these days, being alive is something to rejoice about, so I'll suggest we eat and drink to that. I made Yam porridge this morning. What will you like to drink? Beer? Malt? Whichever one you choose we'll need cups and I don't have any, so why don't we take a walk to the store down the street and get cups, in the process, let me tell you about something, it may look so simple like a regular thing, but trust me, without its careful use, we will neither have malt nor beer to drink.

What am I talking about, what is so commonly fundamental to yam, beer and malt? Of course, I'm not talking about grains, yam is a tuber crop, I'm certainly not talking about planting nor harvesting, you're thinking Storage? If you are, then you're closer to the truth than your first guess. I must confess that I've been recently tempted to talk about the great place of storage in agriculture, however, due to its complexity, I've decided to complete research on some things before I present that.

For that reason you may notice that I've been trying to explain some aspects of Storage recently. Today will be no different, I'll be discussing a process that is so fundamental to Storage, that without it, nothing can really be stored- Drying

Yes, Drying plays a very important part in making sure that agricultural products get to us in a way they can be beneficial to us. What do I mean? When I told you earlier that I boiled some yam for the porridge, you may remember that yam in its natural form has a lot of water, this feature of yam coupled with some other reasons that will be discussed very shortly will make sure that the yam begins to spoil after some time, but if you could reduce this water content to the barest minimum in that yam, then it can stay much longer to the point where it can be transported from the farm after harvest, stored, and eventually distributed until it gets to me-too the final consumer, even until today that I decided to eat it.

What of the grains? You may want to remind me that not long ago, I said it myself that Silos are the Lords of storage when it comes to these, I know I said so. But, I'm sure you know that without citizens and subordinate rulers a Lord is nothing. In the same vein, you will remember that one of the major ways of classifying those Silos depend on the method of aerating them. These methods of aeration are usually associated with how the grains kept in the Silo are kept dry.

Why is there so much fuss about drying, why do agricultural products really need dryino to be successfully stored, what more is there to know about agricultural drying? Allow me to answer those questions and more.

DRYING IN AGRICULTURE

As you already know, drying involves reducing or totally removing moisture from a substance. In the case of agricultural products, though, this moisture can either be water or oils (in the case of oil seeds). It is a process that can occur naturally either through the effect of heat from the sun ornthe movement of air through the products. This natural process has been in use since the existence of mankind and still continues to be used, however both the air and the sunlight that are the tools in this type of drying are non-living and are unconsciously doing the job, so the rate at which the drying occurs and its efficiency can fluctuate and may not readily conform to what is required for a particular crop product.

This reason and others to be explained soon has necessitated the invention of use of drying methods other than the natural ones, and these systems of drying are collectively referred to as Artificial drying. Before going into details of the types of drying available for use, permit me to inform of the reasons why the importance of drying cannot be overemphasized in agricultural storage.

Why Drying is paramount to Storage

I have for you some good news and and some not very bad news, which one first? Okay, the bad news first then. As much as we love our agricultural products, there are many "enemies" working to make sure we don't always get them healthy, albeit most of them work unintentionally. Let me mention some.

Agricultural materials are living materials, and for this reason they carry out metabolism, that is the breakdown of their available reserves, usually as a result of their respiration. One of the products of this metabolism is water, and the more water present in the crop, the more unstable it becomes, and the more prone it is to microbial and pest attack. This metabolism can sometimes hasten ripening and aging in the products beyond the rate that is comfortable for the farmer.

Another property of agricultural materials is what necessitates the drying of those products- they are hygroscopic. What those that coined that English word are actually trying to say is that, those products respond to their ambient weather conditions. This means that when there surrounding has more moisture content than they do, they will absorb moisture, however, when the case is reversed, they release moisture to their surroundings. This goes on and on for as long as the ambience keeps changing, thus rendering the materials unstable, except the material reaches its Equilibrium Moisture Content (EMC) at which point, it becomes stable. The EMC Cam be reached when the product is properly dried.

Did you know?

Trucks transporting fresh products like tomatoes and onions from the North to the Western parts of Nigeria are usually driven at night to avoid as much hygroscopy in the products as possible.

I suppose these ones should be tagged public enemy in storage, I just don't know if they should take the number 1 spot- Insects and micro-organisms. These too, like us, enjoy feeding on agricultural products, we just need someone to tell them that they damage the quality of the products while doing so, not that they will listen though. However, the presence of moisture in products is what predisposes them to attack. Most micro-organisms for example thrive better in moist conditions.

At times, agricultural materials like grains are stored in bulks, at such, while in storage, some parts of them that are not getting enough air, begin to build up moisture, creating wet spots in the stored products, which can eventually spread, resulting in serious damage, quantity and quality loss of the products.

Is the picture I'm painting already too grim? I'm sorry, I'm usually more positive, it's just reality. In any case, the good news is that you can silence all these enemies by properly practicing Drying before and after during storage. How can you go about it? There are some choices you have to make. Let's discuss four of them.

Principle of drying

One of the major choices you have to make in drying is how you actually intend to dry your products. You may feel that the sunlight or natural air movement is enough to dry your products, in this case you will be said to be practicing Natural drying, you could also go for this due to your financial power, since it is cheap. However, it is not usually as efficient as the artificial methods, that is why natural drying is usually used in conjunction with other artificial drying methods to efficiently dry products.

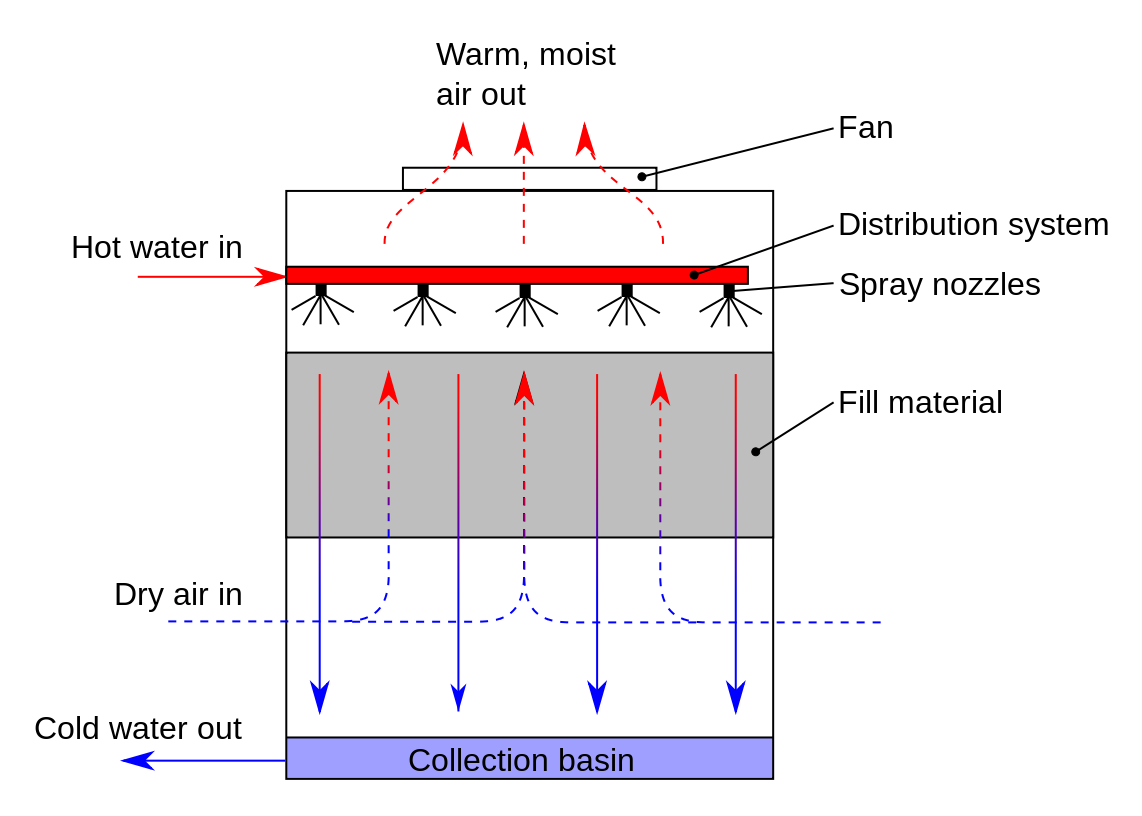

Every other method apart from the natural ways are Artificial, but I said that already, right? In this case, your main drying tools are still heat and air, the difference though, is that you control how and when both of these reach your products. You have the choice of going Mechanical by employing blowers to deliver and circulate the air. Of course, in this case they speed of the blower for different products have to be determined during design for efficient drying.

You could focus on delivering and circulating the heat too. In which case you will be employing the Heating Method, by having a source of heat, either Solar, Electrical or Di-electric, harnessing the heat from these sources and properly delivering them to the products in the heating chamber. The obvious advantage here is that you're in control and for most products (especially food products), you can ensure an hygienic drying process.

How will you circulate the air for drying the material?

Plainly put, you have three options here, and these options are mainly differentiated by how you configure the movement of air relative to the movement of products in the dryer. You may decide to have your air or heat move in the same direction that the materials are moving, that means that the materials are exposed to the highest heat while they are at their wettest point. This is known as Co-current flow Drying. The deeper the products go in the dryer, the lesser heat they experience. Some of these type of dryers have up to three chambers with differing temperatures to ensure efficient drying. They are usually employed when there is need for a high initial drying rate.

A COUNTER CURRENT FLOW DRYER from Wikimedia under CC-BY-SA 3.0 license by Edherer Modified by Zerodamage

Another option is the Counter-current flow Drying, in which case the products and the air flow in opposite directions. It is worthy of note that this means the products are exposed to the highest heat just when they are about to leave the dryer, whereas they experience least drying at the initial stage. Products that are needed at high temperature for processing are usually dried using these method. Products dried under this method for the purpose of storage, however, must be properly cooled before storing to avoid problems in storage.

The final option here combines the principles employed in both of the aforementioned methods such that the materials are exposed to very high heat both upon entering and leaving the dryer, also relatively high heat is maintained throughout the drying process compared to the other methods.

Where will your heat come from?

This question will need to be answered if you plan to employ any artificial drying method. Your source of heat could be from the sun itself if you fancy Solar drying or you live in the tropics where you are more likely to get enough sunlight exposure. You could choose to employ heating elements connected to an electrical source for Electrical drying. If you're not so sure of the availability or cost efficiency of drying with electricity, you may choose to go for heating with Coal.

Another option is a new one and requires enough technical know-how, Di-electric heating. We should also not forget the option of microwave drying, although I've only seen this applied when the quantity to be dried is little.

How to control the process

All of these methods discussed still require effective control to make sure that the drying is efficient and is a success, and how you do this is another decision you have to make. The Conventional method means you will manually determine, monitor and control how much air and heat gets to your products and when. You could decide to leave the determination and monitoring of the conditions to pre-installed measuring devices, but still be the one to effect changes in the drying process if you decide to go Semi-automated. For the Fully-automated system, the determination, monitor and control of the whole drying process is left to an arrangement of sensors and computers that rely on the feedback from the sensors to start and stop the process.

All the four choices you have to make as explained above are the major ways of classifying drying systems.

Drying Rate

When drying takes place, it occurs at the different rates, usually at the beginning of drying, the moisture is removed from the product at a uniform rate in what is called the Constant Drying rate, this is the point where you say Adios to the water of saturation and even the free surface water. However, as you near the end of the process, the rate of moisture removal would have lost its uniformity and now begins to occur at a declining rate in what is termed Falling Drying rate.

Although, heating is an important part of drying, when the purpose of drying is storage, it is important to incorporate cooling systems as an intermediary between drying and storage, else, the whole drying process might be counter-productive after all.

Also, it should be noted that some agricultural products do not only contain water, they also have oil, and for that reason, the temperature at which such oily products are dried is usually lower than that of non-oil products (usually below 46 degrees Celsius. If this is not done, the oil begins to flow from the product, thus rendering the whole process useless and wasting the products.

The purpose of the whole drying process, don't forget is to attain the Equilibrium Moisture content in the products where they become stable before storing them, at this point, the moisture content, temperature and relative humidity are at points that can maintain the product's quality for a very long time, in fact, when properly monitored and managed under automated or controlled atmosphere storage conditions, products can stay in storage for years.

Many of the drying methods mentioned here and some others not yet mentioned work in significantly different ways, while a particular drying method may even have variants. Please check back very soon to know details about these.

REFERENCES

- NAS. 1998. Post harvest losses in the developing countries Publication of the National Academy of Science, Washington, D.C, U.S.

- Okunola, A.A 1995. Equilibrium moisture content and relative humidity of source tropical root crops. Proceeding of the Agricultural Society of Nigeria

- Okunola, A.A. and J.C Igbeka. 2000. Water absorption characteristics of plantain and sweet potato. Proceeding of the Nigeria Institution of Agricultural Engineers, 22:20-25.

- Sinha, R.N 1971. Interrelations of physical, chemical and biological variables in deterioration of stored grains. In: Grain storage Part of the system.

GRAIN DRYING | CO-CURRENT VS COUNTER CURRENT DRYING | DRYING

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details.

Someone's sitting in the shade today because someone planted a tree a long time ago.

Hello! I find your post valuable for the wafrica community! Thanks for the great post! @wafrica is now following you! ALWAYs follow @wafrica and use the wafrica tag!

Here in our country dried fish is a must have in every dining table. Kudos for an excellent article @sogless!

I guess my subconscious picked the first picture for me as I grew up eating different kinds of smoked fish. Thanks for stopping by and for your encouraging comment.

Beautiful one @sogless

You've really shown drying to be a backbone of agricultural storage..An educating one

Good job

Awesome work you did here mate! Long and rich in content

Drying is by far one of the oldest and most effective way of preserving things...

It nice having a post to fully explain and guide one on how to and why we need to

Thanks for this awesome post

Drying works almost too well. Thank you for reading and for your comment.

It's a pleasure

Mr Storage. Nice post. Read about your post on Silos too, and I can see that you're really into developing a good storage system for most products. Nice job man.

I'm glad to have a regular visitor to my blog and that you still keep the things you saw in mind. Thanks.

The Agric business is still Nigeria's surest business. I like that you showed me how it's been done. My point of interest is that you have be to be careful when drying if you have oily seeds together with'water' produce. Thank you!

If the Nigerian government could depend on the Soil like it depends on Oil, things will be a lot different. Countries like Malaysia and Israel have and are still showing what agriculture can do.

You are right here. I think we are bad imitators. Everyone wants to be a techie or the office person. We're slowly running away from our grassroot and it is saddening.

Pretty soon, the folly will hit us in the face.