Kevlar, The synthetic polymer able to save more lives

Kevlar

If you do not know this product, Kevlar, probably think that it is a medicine, but in fact, it is a high strength fiber, ideal for the manufacture of bulletproof vests. The invention of his invention is an interesting story both for the unexpected technological progress that it entailed and for the fact that behind it was an inventor and that unfortunately, the inventions attributed to women have been a minority throughout history, although the situation as in so many aspects of life is changing.

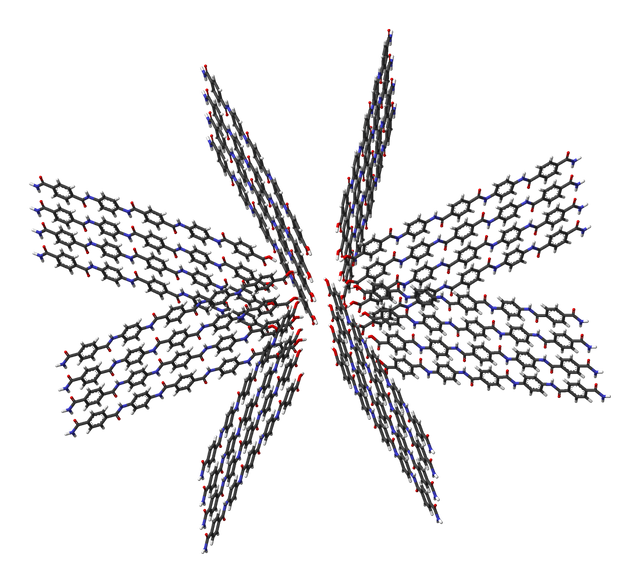

Kevlar is a super strong plastic. The Kevlar properties are due in part to their internal structure (with their molecules arranged in regular and parallel lines) and partly because of the way they are transformed into tightly bonded fibers. It is a synthetic material (manufactured in a laboratory, not extracted from nature)

Chemically it is a synthetic polymer of aromatic polyamide. A polymer is made of identical molecules. Kevlar monomers are based on a modified ring structure similar to benzene.

Discovery

Stephanie Kwolek worked with low-temperature polymers, which when dissolved can become thin fibers. A specific group of these elements was able to produce resistant fibers that decomposed at high temperatures. It was in 1965 that he discovered a liquid polymer that would shortly be known as Kevlar and received his patent in 1971. Stephanie was conducting experiments with polymers when she arrived at results that she considered erroneous; This is because Kevlar is a crystalline solution while most of these elements are viscous in consistency. This is why Kwolek thought, at first, that the discovery had been an accident.

This polyamide contains aromatic groups, among which there are interactions, as well as interactions by hydrogen bonds between the Amide groups. Because of these interactions, insecurity rates are high. In them, the macromolecules look perfectly oriented in the same direction and very well packaged.

Its fibers consist of long strings of poliparafenileno tereftalamida, which can withstand temperatures with which it can be made much lighter, stronger than steel and does not affect corrosion. It is currently used to reinforce mountain garments due to its great capacity and resistance, such as on the shoulders of jackets to avoid wear due to friction with the backpack.

OBTAINING

Kevlar filaments are produced by extruding the precursor through a spinneret Extrusion imparts anisotropy (increased strength in the longitudinal direction) to the filaments. Kevlar can protect carbon fibers and improve their properties: hybrid fabric (Kevlar + carbon fibers) combines very high tensile strength with a high impact and abrasion resistance.

The most popular matrix materials for the manufacture of Kevlar (aramid) Fiber reinforced polymers are thermosetting such as epoxies (EP), vinyl ester and phenolic compounds (PF). Kevlar fiber reinforced polymers are manufactured by open mold processes, closed the molding processes and the pultrusion method. Kevlar's distinctive features are high impact strength and low density.

Properties

Unlike most plastics, it does not melt: it is reasonably good to withstand temperatures and decomposes only at about 450 ° C.

Very low temperatures have no effect on Kevlar: Tests found no degradation up to -196 ° C.

Kevlar can resist the attacks of many different chemicals, even if the exposure is prolonged to acids or strong bases which will degrade over time.

In the tests, Kevlar remained almost unchanged after exposure to hot water.

Uses of Kevlar

Kevlar has played a significant role in many critical uses:

- Ropes, airbags in the Mars Pathfinder landing system

- Small diameter ropes;

- Anti-aircraft shielding in jet aircraft engines, protection of passengers in case of explosion;

- Functional tires that run flat;

- Gloves against cuts, scrapes, and other injuries;

- Kayaks with impact resistance, without additional weight;

- Skis, helmets and strong, light racquets.

- Bulletproof vest.

Although it also has to point out that Kevlar has some drawbacks. In particular, although it has a very high tensile strength, its resistance to compression is very low. That is why Kevlar is not used in place of steel as the main construction material in buildings such as buildings, bridges and other structures where compression forces are common.

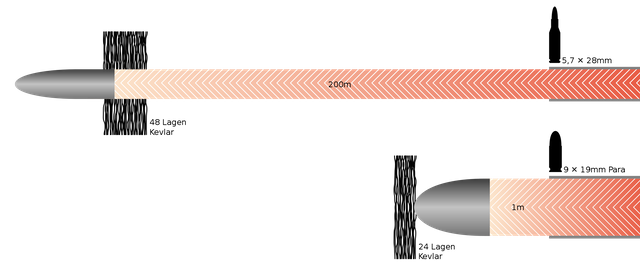

Kevlar can be used alone or as part of a composite material (a material combined with others) to give more strength. Kevlar is an excellent anti-ballistic material because it requires a lot of energy that can be a knife or a bullet through it. The woven fibers of the polymer are very difficult to separate. It takes energy to separate them. A bullet will lose energy while trying to open the way. If it manages to penetrate the material, it slows down considerably, doing much less damage.

Reply to my last blog post everytime you make a blog post and I will upvote and resteem it for free to my 36,000+ followers. @a-0-0