Product Testing, Part 1

Laboratory Testing Of High Quality Products, Part 1

A Laboratory

In industries across the world, and especially in the vast areas of chemical engineering, many processes occur. Many of these processes may differ with respect to chemical compositions as well as objectives, but there is a similarity between these factors. An overall end product. This product that is produced is, in the most ideal case, of superior quality and may contain a 0% impurity composition. Unfortunately, in the real world, these outcomes are of Fairy Tail predictions. In reality, we do not get these highly desirable characteristics in our product, although we strive to meet these criteria. In order to know whether these criteria have been met, certain tests are performed in order to identify the quality of the product streams and also used in facilitating the controls in refinery operations.

In conjunction to my previous posts, I introduced the fluid known as crude oil. To elaborate and explain the types of tests used, I will be using crude oil as an example of the fluid used. There are many test that can be done to criticize the composition of fluids, but the most important tests are:

- API gravity and specific gravity

- Vapour pressure (reid)

- ASTM distillation

- Flash and Fire points

- Colour

- Viscosity

- Cloud and Pour points

- Knocking characteristics

- Sulphur tests

- Gum and gasoline

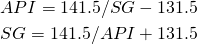

API gravity and specific gravity

This is a form of testing that allows us to evaluate the physical characteristics of crude oil. It allows us to inspect the density of the fluid, and in doing so, allows us to determine which fraction of crude oil the fluid belongs to.

The API of the entire fluid (the stabilized crude oil) gives us an accurate indication of the magnitude of products that are of a lighter distillate that are likely to be present.

Specific gravity is an indication of how well a fluid/ a material floats in relation to that of water. It is a ratio of the density of the fluid/ material as well as the density of water.

Equations

It is important to note that as the density of the product increases, the yield of the lighter fractions of crude oil (such as that of gasoline, kerosene as well as naphtha) decrease. Consequently, as the density increases the degree of API decreases.

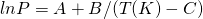

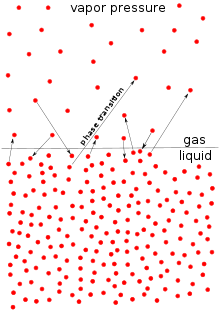

Vapour pressure

Vapour pressure, as well as reid vapour pressure , abbreviated as RVP, is often referred to as the magnitude of absolute pressure that is exerted by that of molecules in the vapour phase, when these molecules are in thermodynamic equilibrium with that of the other two phases (i.e. liquid and solid) in an isolated system. Vapour pressure can be calculated using the Antoine equation, whereby each constant in the equation has a numerical value that differs from molecule to molecule:

Antoine Equation

Vapour pressures are used to determine the relative volatility of our fluid. It is also used as a safety indication, as it is used to monitor the pressure build-up within vessels on a plantation site.

RVP measures the absolute vapour pressures of many volatile products in the petroleum industry using ASTM method, which will be explained next.

ASTM Distillation

ASTM Logo

ASTM is an abbreviation for the American Society for Testing Materials. ASTM was established in 1898 and is situated in Pennsylvania of the United States of America. ASTM is an organisation that tests certain properties of materials and releases the results found upon testing. There are more than 12 000 ASTM standards worldwide. In the production of crude oil, the results obtained from the testing of distillation is required from ASTM. More especially, the boiling point tests are required for fluids such as naptha, gasoline, kerosene as well as gas oil fractions. These obtained values, which are often extremely accurate, is used to generate a plot of the boiling point of each fluid against the percentage of distillation achieved, for each fraction. This plot allows us to identify the optimal boiling point, for which maximum distillation will occur. It will also allow us to compare the distillation achieved for every fluid at the same boiling point. From the result, we identify a compromise boiling point, in which a maximum amount of distillation can occur for all components of the fluid. This form of test also allows us to predict the amount of energy, in the form of heat, that will be required.

Flash and Fire points

Flash and Fire points is a form of testing that is strongly correlated to a safety measure in the working place. These points indicate to us a maximum threshold in relation to the physical property that is being investigated.

A flash point is the temperature of an environment at which vapour, that is above a present oil in the environment, will come into contact and in turn explode in the presence of an open flame. This test is of extreme importance in not just crude oil production but all chemical engineering processes, as vapour is always present in experimental procedures.

A fire point is the temperature at which the present vapours in an environment can evolve rapidly enough to burn continuously at a constant or non constant rate. This can be due to the present vapours in the environment, as well as the combustibility of fluids present.

Colour

Colour is a factor that many people take for granted daily. Colour brightens up our lives and allows us to view all that is present, but what many people do not understand is that colour is also an important factor that is used in industry. Colour is a property that is directly related to the degree of refining and the quality of a product.

Colour

For a process in which a high quality final product is of a dark brown colour, any other colour of product would be an indication of inferior properties. This would immediately indicate that the process needs to be repeated and the deteriorating step, in which the inferior product was produced, must be identified and corrected.

In the production of crude oil, a Saybolt Chromometer is used, and this is used to identify the colours required for high quality gasoline and oil products. On the colour scale range, gasoline has a reading of approximately 30.

Testing Processes

This brings us to the end of my first installment on laboratory testing for high quality products. We must understand that in my posts I make reference to crude oil as an elaboration. These tests occur on many other products also, and some products may require even further testing. Thank you for your time.

Images are linked to their sources in their description

The End

References:

[1]https://en.wikipedia.org/wiki/Laboratory

[2]https://www.engineeringtoolbox.com/api-gravity-d_1212.html

[3]https://www.britannica.com/science/specific-gravity

[4]https://www.astm.org/Standard/standards-and-publications.html

[5]https://www.astm.org › Standards & Publications

[6]https://www.ilpi.com/msds/ref/flashpoint.html

[7]https://en.wikipedia.org/wiki/Fire_point

[8]https://en.wikipedia.org/wiki/Crude_oil_assay

[9]https://www.intertek.com/petroleum/testing/crude-oil-quality/

Congratulations @akeelsingh! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard!

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes

Congratulations @akeelsingh! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on the badge to view your Board of Honor.

If you no longer want to receive notifications, reply to this comment with the word

STOPDo not miss the last post from @steemitboard!

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes