Equipment of Filtration, Part 3

Filtration Equipment, Part 3

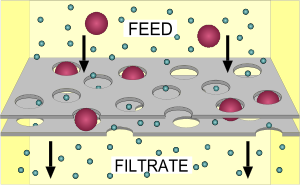

FiltrationImage Credit: https://en.wikipedia.org/wiki/Filtration

As a recap, filter media is the choice of material for a medium, through which, the slurry is passed through. In the filtration process, the choice of filter media is one of the most important factors to take into consideration when the cycle is occurring. The reason for this is due to the fact that the filter media can increase the overall efficiency of filtration but only dependent upon the quality and the selected choice of filter media.

Types of Filter Media:

In my last post, I introduced the concept of filter media as well as the requirements that need to be met by the media that is chosen. To elaborate on this topic, it is important to note that one of the advantages of filter media is due to the reasoning that filter media have individual types available in a wide range of very materials such as:

Incorporation of Filter MediaImage Credit: Self Image

- Media of fabrics that consist of woven fibres

- Media that consist of metal fabrics as well as contains screens or parallel plates (extremely thin plates)

- The most convenient filter papers

- Media that consist of membrane thin material such as polymer membrane

- Cotton batting as well as pressed felts

- A porous media that has the physical properties of being rigid and strong.

Filter Aids:

In any process in the industrial world, it is often identified that a process can never be completed satisfactorily without a few problems along the way. In order to either avoid these problems or to derive a solution to them, engineers would have to create a method in which the end product shall be of satisfactory quality. The process of filtration is no exception to the above and also incurs a few problems during the process. Since some of these problems cannot be avoided, engineers created a technique known as filter aids to help solve these problems that cannot be avoided. The problems that cannot be avoided during the filtration process are often:

The low yield produced due to the slow rate of filtration, the binding of the medium chosen that occurs rapidly, as well as the unsatisfactory filtrate that is produced due to it’s undesired low clarity.

Production of High Quality FiltrateImage Credit: https://commons.wikimedia.org/w/index.php?search=filtration%27&title=Special:Search&go=Go&searchToken=a1ge3s95yko3rvooni1f0t4lv

Filter aids are generally solids that are made of other granular or fibrous material that are incorporated to either the slurry or the filter cake to facilitate and eradicate the aforementioned problems with filtration. The reason why it’s chemical components consists of these types of material is due to the fact that a filter aid needs to have the characteristics of a highly permeable membrane, thus forming a highly permeable filter cake in the end product. All processes can not be conducted with 100% efficiency and in this method, the product (a solid), may contain certain impurities that are small enough to fit through this membrane. Due to this reason, the filter cake can be noted to often have very fine solids of slimy, deformed floccs (produced via flocculation) that are trapped within the cake.

In industry, economical efficiency is an important factor in the everyday operation of a plant. For maximum efficiency, all factors relating to that particular process plant must be at its highest work rate. In order for this to occur, the quality of materials being used must be extremely high. When related to our sub topic of filter aids, high quality characteristics should include having a low bulk density (as this minimises the settling time and distribution, as well as facilitates good distribution on the filter medium). Filter aids should also be porous and have the capability of forming a porous cake filtrate, when required. When these factors are met, it allows us to filter in any non-horizontal manner ,which is an added advantage to the process, but only when high quality materials are used.

Filter Aids Applications:

Filter aids are extremely versatile due to their extensive range of uses as well as ways of applications. The filter aid used can either be added to the slurry before filtration or by pre-coating the slurry before filtration. It should be noted that the most frequently used method is by adding the filter it to the slurry. In this method, the filter aid can be easily separated by the filter cake (after filtration), by either dissolving away the solid compounds or burning out the filter aid. If the solids in the filter cake have no value to the industry, meaning that the filtrate (liquid portion) is of value, the solids and the filter aid, (which are amalgamated together in the cake) can be discarded. Due to this self-sufficient way of getting rid of the filter aid, this method is more widely used than pre coating.

Examples of Filter Aids:

Physical Appearance of a branch of SilicaImage Credit: https://en.wikipedia.org/wiki/Silicon_dioxide

Diatomaceous Earth: this is an example of an extensively used filter aid which has a dry bulk density of between 128 to 320 kilograms per metre cubed and has a chemical composition that consists mainly of silica. The microscopic properties of this filter aid include, consisting of particles that are smaller than 50 micrometers and producing a filter cake with a porosity of almost 0.9. It is worthy to note that the porosity of randomly packed uniform spherical particles are only 0.38 and for a typical filter cake the porosity is between a low 0.2 to 0.3, thus the high porosity of diatomaceous silica indicates a high filter aid ability.

Perlite: another commonly used filter aid is known as perlite. Perlite has a lower bulk density than that of the previously mentioned filter aid, in a range of between 48 to 96 kilograms per metre cubed and contains a higher fraction of particles in the range of between 50 to 150 micrometers. Although it may seem that perlite has more favourable characteristics then diatomaceous silica, it's low porosity of 0.6 (when compared to diatomaceous silica) hinders it’s abilities as a filter aid.

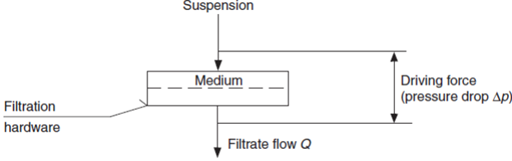

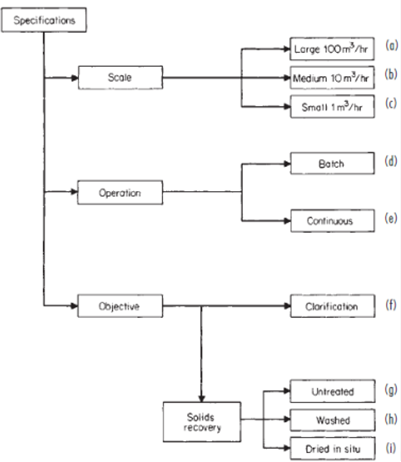

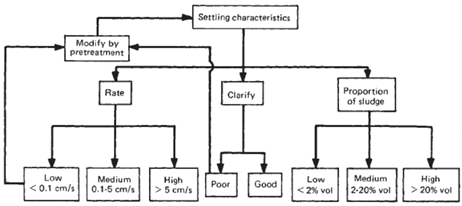

Selection of filtration equipment

Along with material quality, proper selection of filtration equipment is an important aspect that contributes to the overall efficiency of a process, thus, the choice of filtration equipment is extremely important. Although there no direct or proper selection techniques available, a published suggestion guide was created by engineers who have experiences in these fields as well as experiences working with these individual pieces of equipment. This process was referred to as the “Method of decision tree” by Tiller in 1974. In the years to follow, this method was refreshed and further adapted to the newer evolved equipment available at that point in time. This new method was referred to as the “Coding Method”, which was proposed by Purchas in 1987. This method can be evaluated below,

Method 1 Image Credit Self Image

Method 2Image Credit: Self Image

This brings us to an end of my 3 part series on filtration equipment. I hope that this has broadened your knowledge on the processes in a chemical engineering plant as well as giving you insight into the different methods applied in industry.

Images are linked to their sources in their description

The End

References:

[1]https://www.aquamat.co.za/filter-media

[2]https://en.wikipedia.org/wiki/Media_filter

[3]Coulson and Richardson's Chemical Engineering. Vol. 2, Oxford, ButterworthHeinemann by RICHARDSON, J. F., HARKER, J. H., BACKHURST, J. R., & COULSON, J. M. (2002).

[4]https://www.eaton.com›Home›Products&Solutions›Filtration

[5]Unit Operations of Chemical Engineering by McCabe W.L., Smit J.C. and Harriot P (McGrawHill, 7th Edition, 2005)

Hello @akeelsingh you have done a good job here but as part of the Steemstem mentor team, I have noticed you should properly reference your images. For example, this is how I would do the first image:

Filtration. Image Credit: Wikiwayman at English Wikipedia

Note that user Wikiwayman has asked to be attributed this way when you click on the image credit link.

Hi @terrylovejoy, thank you for your feedback, i really appreciate it. I will definitely update my further posts to this layout. Thank you again.

My pleasure @akeelsingh , thanks for your understanding. I know had to correct one of my posts recently for the same reason :)

I shall re-edit it now :)

Congratulations @akeelsingh! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

To support your work, I also upvoted your post!

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP