WHY USE STEAM CLEANING VS. HOT OR COLD WATER WASHING?

This article discusses how using steam differs from using high pressure hot water to clean – including reduced runoff and power consumption. All steam cleaners are not equal; some provide much greater output and cleaning effectiveness than others which may appear similar. There are numerous applications where users obtain significant savings and improved performance using steam. Understanding these differences will help you select the right equipment, which can save you time and money and can improve the capabilities of your organization.

TYPICAL APPLICATIONS FOR STEAM

Cleaning engines, transmissions, drive trains, and other equipment prior to performing service and maintenance work.

Thawing frozen drains, tanks, piping systems, culverts, etc., for street and highway departments, manufacturing and processing plants, pipelines, and other industries.

Thawing railroad tank cars to accelerate removal of viscous liquid contents, while ensuring that the maximum temperature is less than the boiling point of water (to prevent fires and other high temperature damage).

Removing chewing gum from sidewalks, tables, stadiums, entryways, etc.

Degassing tanks prior to welding or other maintenance work, especially gasoline, oil, and petrochemical tanks of all sizes.

Preparing surfaces for painting, especially removal of cutting oils, grease, and similar oily or greasy substances.

Degreasing dies and tools in manufacturing operations.

Removing fats, grease, oils, and substances from surfaces and equipment in food processing plants.

Melting and removing paraffin and wax or grease from traps and drains in wastewater treatment plants, petroleum refineries, and for similar use in other industries.

Cleaning and restoring brick, block, stone and other masonry surfaces for maintenance or restoration projects, at monuments, cemeteries, and similar applications, where steam is more gentle and less intrusive and damaging than high pressure cleaning.

Wide range of other specialty applications.

Vapor Expansion: The Key to Steam Cleaning

Although a cleaning machine may be capable of producing both heated high-pressure water and steam, there's a huge difference in the way the two cleaning processes work. In a pressure washer, a high-pressure, positive-displacement water pump simply pushes water through a restrictive nozzle. The narrow diameter of the nozzle increases the water's velocity and, consequently, its impact and cleaning power. In pressure washing, the restrictive nozzle is the last part of the machine through which water flows.

Steam Cleaning Is A Different Process

Steam cleaning is an entirely different process. The steam cleaner uses steam’s expansion to accelerate water droplets, at the boiling point, to a high velocity.

The closer the steam cleaner's nozzle is to the surface to be cleaned, the higher the temperature and velocity of the water/steam mixture, and the more rapid the cleaning action. The temperature of the water/steam mixture drops quickly as the distance between the nozzle and the surface to be cleaned increases. Consequently, for many cleaning applications, the nozzle should be held close to the soiled surface to achieve the best results.

320°F (160°C) Water

Water in a steam cleaner is heated to 320°F (160°C) at relatively low pressure (in the 100 to 250 PSI (96.9 to 17.24 BAR) range vs. 2,000 to 4,000 PSI (137.9 to 275.8 BAR) for the most common pressure washers), depending on the model.

Water at atmospheric pressure (14.696 PSI (1.01 BAR)) boils at 212°F (100°C). At higher pressure, it takes more energy to convert water molecules into steam, so the boiling temperature increases. At lower than atmospheric pressure, such as high altitude, the boiling temperature is less than 212°F (100°C).

Water in a steam cleaner is compressed to 250 PSI (17.24 BAR) by the pump, and heated to 320°F (160°C) prior to nozzle discharge. Water at this temperature remains a liquid at any pressure over 89.7 PSI (6.9 BAR).

Volume Expands by 1,517 The specific volume of water at 320°F (160°C) is 0.01765 cubic ft. / lb. of water. When water flashes into steam at 212°F (160°C), the specific volume increases to 26.78 cubic ft. / lb. The ratio of the final volume divided by the initial volume is 26.78 / 0.01765, which equates to 1,517 times its former volume. Therefore, when water vaporizes to steam (boils), it expands to 1,517 times its former volume.

Flashing To Steam

After the 320°F (160°C) water in a steam cleaner passes through the restrictive nozzle it is no longer under the additional pressure of the water pump and can not remain a liquid. Fifteen percent of the water instantly flashes into steam, cooling the mixture of steam and water from 320°F (160°C) to 212°F (100°C). This steam vapor, used with a properly designed steam cleaning nozzle, also accelerates the remaining water droplets.

Unlike a pressure washer nozzle, the steam cleaning nozzle has an expansion zone placed past the pressure orifice, which directs the water vapor energy to a smaller area, instead of dissipating in all directions. The tremendous expansion is directed by the conical steam nozzle, accelerating the water droplets. The expansion nozzle's effect can be compared to that of the choke of a shotgun. Not only does the expansion nozzle direct the steam cleaner's output, it serves as a propulsion chamber. The expansion nozzle both directs and accelerates the output.

Optimum Temperature and Pressure

A temperature of 320°F (160°C) and a pressure of 100 to 250 PSI (6.9 to 17.24 BAR) are considered optimum for a steam cleaner design.

Optimum Pressure: A steam cleaner could be operated at higher pressure by increasing the pump size, however, that would produce smaller water droplets, which would cool more quickly. The larger droplets also possess more mass, which increases the effect of their impact - much as a .45 caliber slug strikes with more authority than a .22 caliber bullet. Optimum Temperature: At temperatures above 320°F (160°C), excessive water would flash to steam, again producing smaller water droplets having less mass and impact. In addition, components, controls, guns, hoses, and accessories are cost prohibitive or are not available at higher temperatures. At lower temperatures, significantly less water is vaporized to steam, and consequently less propulsive energy is transferred to the water/steam discharge mixture, as shown in Table 1 later in this document.

Steam Nozzles: When a standard hot water pressure washer nozzle is used on a steam cleaner, the wide-angle spray design does not direct or accelerate the steam/water mixture. The result is a blossoming effect where the steam expansion cannot accelerate or direct the water droplets, and the effective cleaning capability is lost. Therefore, a properly designed steam cleaning nozzle is required for best results. In summary, steam cleaning action is not accomplished by a cloud of steam vapor, but by very hot water droplets accelerated by steam expansion in the nozzle. This process allows the water to reach the surface to be cleaned at a temperature as near the boiling point of water as is possible, enhancing the aggressiveness of most cleaning chemicals and making the task of thoroughly removing grease and oil much easier and faster.

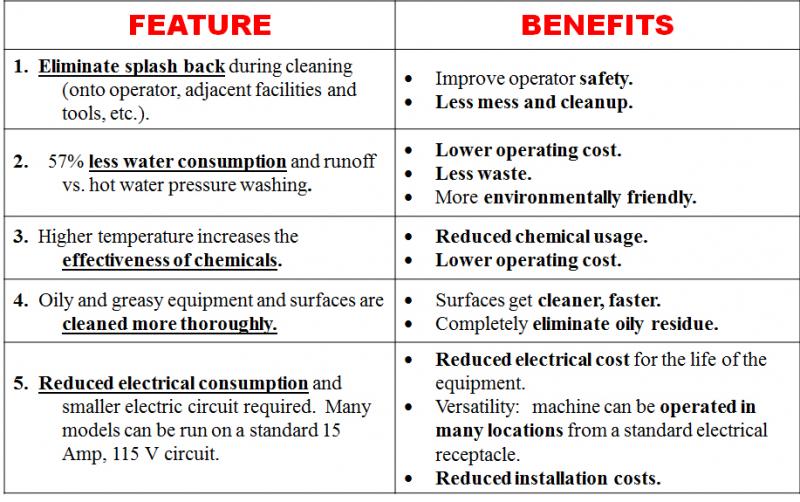

Advantages of Steam Cleaning Over Pressure Washing The following is the central question in the debate between steam cleaning versus hot water pressure washing: Is there still a place for steam cleaning in the power cleaning equipment marketplace?

Steam cleaner users and manufacturers respond enthusiastically to such questions with emphasis on steam's ability to cut grease and oil, and completely clean oily parts for painting, refinishing or rebuilding.

Pressure cleaning, even with hot water machines, leaves an oily film on surfaces.

High pressure washing splatters an oily mess back onto the operator and around the cleaning area more often than low volume, high temperature steam cleaning.

Higher steam temperatures enable faster and more effective sanitatizing, in a wide range of applications.

Steam supporters say that heat is steam cleaning's real advantage. Chemicals are more effective at the higher temperatures provided by steam cleaning, making emulsification of soils easier.

Steam cleaning removes more greasy soil with less water, resulting in less runoff.

With less runoff liquid, there is a smaller volume of waste to be handled, reducing the cost of the handling and disposal.

There is less splatter from steam cleaning, and the soiled water is therefore more easily contained for treatment. (Many ideas above are from Pressure Points Magazine, August 1989)

50% Water Reduction / 57.5% Runoff Reduction

If heat is what is really needed for cleaning, as is the case in many applications, a steam cleaner is the better choice. A 4 GPM (15.4 LPM) hot water washer has an input BTU rating of about 320,000 BTU/Hr, as does a 2 GPM (7.57 LPM) steam cleaner. Both transfer nearly the same quantity of heat to the surface to be cleaned. Since the water flow through the steam cleaner is half that of the hot water washer (2 vs. 4 GPM (7.57 vs. 15.4 LPM)), and 15% of the discharge water leaving the steam cleaner nozzle evaporates, (and in addition a higher percentage of the remaining hotter water, near the boiling point, evaporates), the steam cleaner produces (0.5) X (.85) = 42.5% of the runoff water compared to a hot water pressure washer, resulting in a 57.5% reduction in water runoff. Less consumption, less runoff, and less waste = LOWER OPERATING COSTS.

Smaller Electrical Circuit and Less Power Consumption

A steam cleaner has a smaller pump and motor, since it only needs to produce 100 to 250 PSI (6.9 to 17.24 BAR), not 2,000 to 4,000 PSI (137.9 to 275.8 BAR) as with a hot water washer. Therefore power consumption is significantly reduced, and a smaller electrical circuit is required, meaning it may be connected at more receptacles in shops or plants. Lower power consumption and lower installation cost = LOWER OPERATING COSTS.

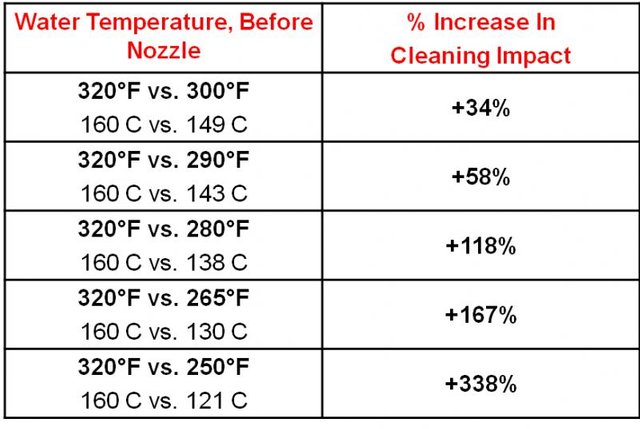

All Steam Cleaners Are Not Equal

All steam cleaners are not designed or created equally, and they do not perform equally! Discharge temperature makes a TREMENDOUS difference in cleaning quality. When the discharge temperature is increased, more of the heated water flashes to steam after it passes through the nozzle. The hotter the water, the more steam is produced, providing a substantial increase in water droplet acceleration and cleaning capability. The following chart shows the tremendous difference in cleaning impact comparing 250-290°F (lowest impact) to 320°F (highest impact). High impact provides a tremendous 338% increase in cleaning capability and speed. Increased cleaning speed = LOWER OPERATING COSTS.

Applications for Steam

Heat is one of steam cleaning's biggest advantages. The steam cleaning process delivers water at a temperature near 212°F (100°C).

If chemicals are used, the higher discharge temperature of a Sioux steam cleaner will increase the effectiveness of chemicals, significantly reducing chemical consumption and costs. In some cases, Sioux’s higher temperatures have completely eliminated the need for any chemicals or detergents, providing a benefit in environmentally sensitive areas. However, chemical and detergent use will usually improve cleaning speed and effectiveness, especially when removing grease and oil based substances. If chemicals or detergent can be used, they are usually recommended.

Less chemical consumption = LOWER OPERATING COSTS.

For cleaning applications where heat increases the effectiveness of cleaning, steam cleaning will dramatically increase the effectiveness of the cleaning operation. For example:

Cleaning engines, transmissions, drive trains, and other equipment prior to performing service and maintenance work.

Thawing frozen drains, tanks, piping systems or culverts, for street and highway departments, manufacturing and processing plants, pipelines, and other industries.

Thawing railroad tank cars to accelerate removal of viscous liquid contents, while ensuring that the maximum temperature is less than the boiling point of water (to prevent fires and other high temperature damage).

Removing chewing gum from sidewalks, tables, stadiums or entryways.

Degassing tanks prior to welding or other maintenance work, especially gasoline, oil, and petrochemical tanks.

Preparing surfaces for painting, especially for removal of cutting oils, grease, or other oily/greasy substances.

Degreasing dies and tools in manufacturing operations.

Removing fats, grease, oils, and substances from surfaces and equipment in food processing plants.

Melting and removing paraffin, wax or grease from traps and drains in waste water treatment plants, petroleum refineries, and other industries.

Cleaning and restoring brick, block, stone and other masonry surfaces for maintenance or restoration projects, (monuments, cemeteries, and similar applications), where steam is more gentle and less intrusive and damaging than high pressure cleaning.

Wide range of other specialty applications.

nice bro

thanks

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

http://www.sioux.com/why-steam.html

good article

thnks

nice article

thanks