Obama's getting hammered.

As promised in a previous post I started to hammer out this Obama silver round. https://steemit.com/silver/@dirtyhippie/to-hammer-or-not-to-hammer-that-is-the-question It might take me a while to get around to making some jewelry out of it.  I'll just leave it like this for now, until I need the silver. It needs to be hammered till it's about half as thick as it is now.

I'll just leave it like this for now, until I need the silver. It needs to be hammered till it's about half as thick as it is now.  The one on top is a silver round I pounded till it's around 20 guage. All the little silver balls I melted down yesterday from scraps. They are nice to solder to rings and pendants as an accent.

The one on top is a silver round I pounded till it's around 20 guage. All the little silver balls I melted down yesterday from scraps. They are nice to solder to rings and pendants as an accent.  In order to hammer it that thin you have to "anneal" it. Annealing the metal is a process that softens the silver so it doesn't crack. Take a blowtorch and heat the silver until it is a dull red hot. Drop it in a container of cool water and it's annealed. Fine silver doesn't get fire scale like sterling silver does, so it's a pretty quick process. Just clean it with a brass wire brush or some 1200 grit sandpaper. Then it's time to hammer some more.

In order to hammer it that thin you have to "anneal" it. Annealing the metal is a process that softens the silver so it doesn't crack. Take a blowtorch and heat the silver until it is a dull red hot. Drop it in a container of cool water and it's annealed. Fine silver doesn't get fire scale like sterling silver does, so it's a pretty quick process. Just clean it with a brass wire brush or some 1200 grit sandpaper. Then it's time to hammer some more.  This garnet ring is an example of one I made from a silver round. The setting is made from sterling silver tubing. I'll do a detailed blog on making a tube setting in the future. https://www.mygypsystore.com/store/dirty-hippie-designs/ Here's a link to my online store. Lots of jewelry and some gemstones for sale. If you love silver don't forget to upvote, follow, and resteem. Thanks so much #steemit

This garnet ring is an example of one I made from a silver round. The setting is made from sterling silver tubing. I'll do a detailed blog on making a tube setting in the future. https://www.mygypsystore.com/store/dirty-hippie-designs/ Here's a link to my online store. Lots of jewelry and some gemstones for sale. If you love silver don't forget to upvote, follow, and resteem. Thanks so much #steemit

Obama finally got hammered! I was thinking about this the other day actually. Was looking at some jeweler and lapidary videos -- what a messy hobbie! I look forward to it!

"The complete metalsmith" by Tim Mccreight is a great book you can pick up pretty cheap. That and another titled "the design and creation of jewelry" were the required texts when I fisrt took a jewelry class in Junior College. I still refer to the metalsmith book to this day. Is there a mineral and gem society in your county? Sometimes they teach lapidary classes and such. I used to teach the junior classes at one in Sonoma County. I really need to join our local club but my truck hasn't been that reliable lately.

Thanks for the tip! My wallet hasn't been that reliable lately for much of anything so I feewl you there. Wanting to get out there and make stuff happen is easier said then done.

I would think that there is a mineral and gem society around here...this is agate central. I'll have to look it up.

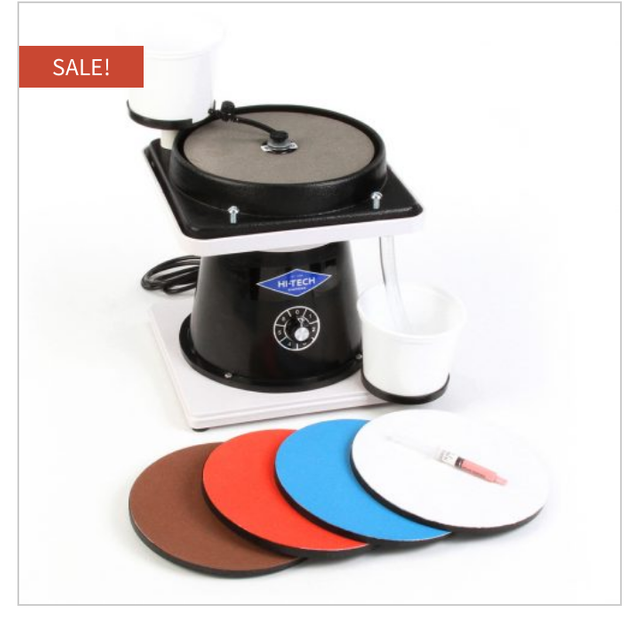

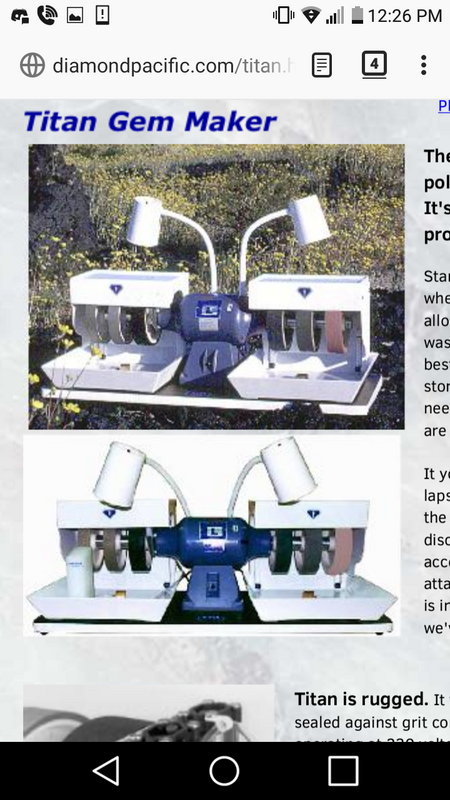

https://hitechdiamond.com/shop/all-u-need-lap-machine/ here's a link to the site for the cabbing machine I have. It be different than what you would want to build. One with verticle wheels might suite you better. These are pretty inexpensive as far as cabbing machines go. Check out the Titan from Diamond Pacific Co. If you could afford their Nova wheels and design a machine around that, you would have an amazing unit.

It be different than what you would want to build. One with verticle wheels might suite you better. These are pretty inexpensive as far as cabbing machines go. Check out the Titan from Diamond Pacific Co. If you could afford their Nova wheels and design a machine around that, you would have an amazing unit. a "Cab King" is another popular unit that is pretty popular lately. The wheels wear out fast so people put the Nova wheels on them...

a "Cab King" is another popular unit that is pretty popular lately. The wheels wear out fast so people put the Nova wheels on them...

Here's the same saw I use. Some people buy a cheap tile saw and put a good lapidary blade on it...

Hope you find one. Sometime's a club will have equiptment sometime's not. Certainly a good place to start though. My health hasn't been the best this winter. My wallet and truck are suffering as a result lol.

I've been watching a lot of DIY videos on how to build my own equipment. My buddy is a machinist, so he knows how to make the pieces I need. Also has a few belt sanders, but we need to make it safe.

One of my friends kept sanding his rocks dry, but I convinced him to stop until we can get some water involved. It'll be quite the project this summer that I plan on sharing here! Speaking of which -- would you share pictures of your tools? I'd love to see what all you use.

Ya working on stones dry is really bad idea. Serpentine and abalone shells have asbestos in them. I'll steal some screenshots of the machines I use off their websites. Be easier than dragging my saw out of my trailer lol.

Here's my unit set up in the sink of an old fifth wheel. I don't really care about the plumbing, so I just let the sludge of rock bits and water drain down the sink. Lol messy buisness for sure.

Thanks for all the info! Much appreciated! It's the results that counts, the set-up looks great!

I can't do any heavy production work on it, but it works for me. The main problem with this type is how long it takes to dry and change the wheels out. It takes like 10-20 minutes before you can move on to the next grit. Pretty time consuming so I don't usually sell the cabs by themselves... Nice to be able to make whatever I need for jewelry and sell some of my extras.

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by dirtyhippie from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.

🔨 Bam

I like how you did this ring!!

Your work is so beautiful!

Nicer setting!

I really am a fan of the tube setting. Prong settings are doomed for failure, eventually...

And thank you.