Tsinghua University team develops ideal extreme ultraviolet photoresist material, achieving a new record of 18nm linewidth

Professor Xu Huaping's team at Tsinghua University recently achieved a major breakthrough in the field of extreme ultraviolet (EUV) photoresists, successfully developing a new polytelluroxide (PTeO)-based photoresist that achieves a new record-breaking 18-nanometer linewidth and lays the foundation for the design of next-generation EUV photoresists. This achievement is not only technologically significant but also provides key support for China's independent and controllable development of high-end chip manufacturing.

As integrated circuit manufacturing continues to advance toward 7nm nodes and below, 13.5nm wavelength EUV lithography has become a core technology for advanced chip manufacturing. However, the high reflection loss and low brightness of EUV light sources pose significant challenges to photoresists in terms of absorption efficiency, reaction mechanisms, and defect control. Current mainstream EUV photoresists rely on chemical amplification mechanisms or metal-sensitized clusters to enhance sensitivity, but these often face challenges such as complex structures, uneven component distribution, prone to reaction diffusion, and the introduction of random defects.

According to Tsinghua University's official website, overcoming these bottlenecks and constructing an ideal photoresist system has become a core challenge in the current EUV lithography material field. Academics generally agree that an ideal EUV photoresist should possess the following four key elements: first, high EUV absorption to reduce exposure dose and improve sensitivity; second, high energy efficiency to ensure efficient conversion of light energy into changes in the photoresist material's solubility within a small volume; third, molecular-scale uniformity to avoid defect noise caused by random distribution and diffusion of components; and fourth, minimal building blocks to eliminate the impact of elementary feature size on resolution and reduce line-edge roughness (LER). For a long time, few material systems have been able to simultaneously meet all four criteria.

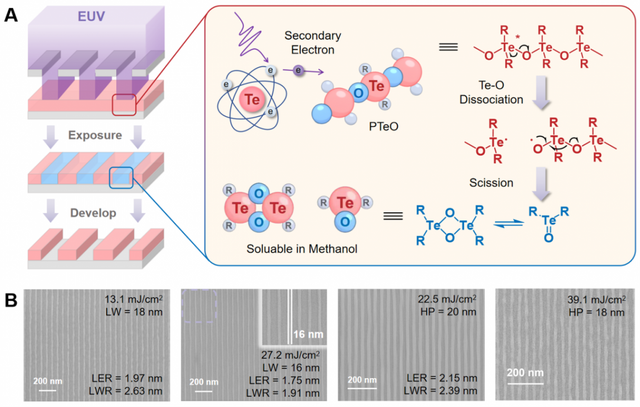

Professor Xu Huaping's research team, based on their earlier invention of polytelluroxane, has developed a new EUV photoresist that meets these ideal requirements. By integrating tellurium into the polymer backbone, the team designed a homogeneous photoresist system with high absorption and energy efficiency. This photoresist achieved an 18nm linewidth and a low line-edge roughness (LER) of 1.97nm at a dose of 13.1 mJ/cm², significantly outperforming conventional photoresists. Polytelluroxane is unique in that its backbone contains tellurium-oxygen (Te-O) bonds. These weak bonds easily break under extreme ultraviolet (EUV) light, resulting in excellent positive-tone lithography performance.

Compared to traditional chemically amplified photoresists or metal oxide photoresists, polytelluroxane has a simpler structure and synthesis method, and eliminates the baking step, making it more efficient and economical in practical applications. Furthermore, the high absorptivity and uniformity of polytelluroxane help reduce random defects in the photoresist, which is crucial for achieving smaller feature sizes in advanced processes.

This research finding provides a clear and feasible path for the design of next-generation EUV photoresists. This photoresist design approach, combining the highly absorptive element Te, a backbone cleavage mechanism, and material uniformity, is expected to advance the development of next-generation EUV lithography materials and contribute to innovations in advanced semiconductor process technology.

More semiconductor related information: https://www.avaq.com/technology