3D Artificial Bones Created to Repair Fractures

Thanks to 3D printing, artificial bones can be used in surgery, to alleviate dental problems and even cure bone cancer.

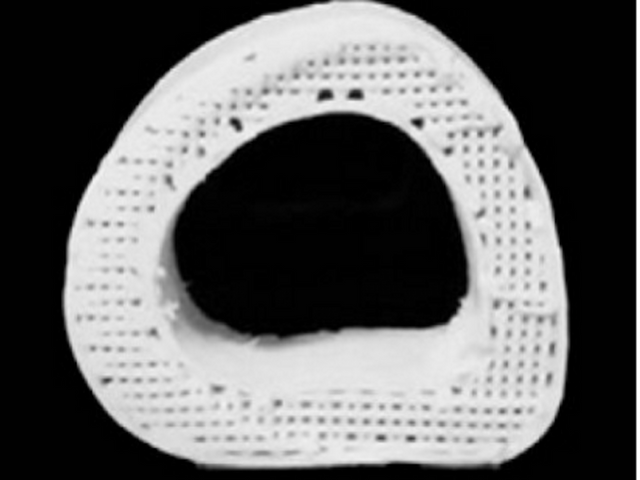

A team of American engineers has developed a 3D printable ink that produces implantable synthetic bone that induces natural bone to regenerate and grow. This hyperelastic bone material, whose shape can be customized, could be very useful for treating numerous problems, including deficiencies or defects in the skeleton of children, as well as for repairing more complicated fractures.

Currently, for this type of large fracture, various solutions are used, such as bone autografts, calcium phosphate products, fillers or mechanical implants. But in the future it could be possible to create personalized and cheap implants thanks to this 3D printing system that will allow the manufacture of custom-made artificial bones. So far, scientists at Northwestern and Illinois University, authors of the study, published in the journal Science Translational Medicine, have already successfully repaired damage to the spine of rats, as well as a malformation of the skull of a Rhesus monkey. These implants - called hyperelastic bones - are flexible and resistant, can regenerate damaged bone without assistance and are easy to place during an operation, as they are very porous, facilitating cell migration and allowing blood vessels to infiltrate.

Bone grafts are expensive and too fragile and difficult for surgeons to handle, while these artificial bones can be used to treat dental problems, perform plastic or reconstructive surgery, and even cure bone cancers. The material they are made of is bioactive and induces differentiation of stem cells into bone-forming cells, according to the researchers who made them. 75% of its total volume is composed of hydroxyapatite, the main mineral of natural bone, which avoids possible rejection or reactions to a foreign body, as can occur in natural bone grafts. The other component is the polymer that serves as a cement, poly-lactic acid-co-glycolic acid or polycaprolactone, which is used as a suture material. They are biocompatible and biodegradable polymers. Known and safe synthetic materials have been used to reduce the possible side effects of the interventions.

The physical and mechanical properties of these materials allow for the creation of customized implants that are tailored to the problems of each patient, and will be even more effective when applied with the help of CT images, which were not used in experiments with rats and monkeys. What the experts did was print approximately sized bones and then trim the material to fit the precise measurements in each case. Even so, the implants were able to integrate with the surrounding tissue until the vertebrae of the rats and the cranial malformation of the macaque healed, without infections or other side effects. That's why the field of 3D printing seems to have an extraordinary future.

Congratulations @interesting4u! You received a personal award!

Click here to view your Board of Honor

Congratulations @interesting4u! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!