Vaccum pumping system and its types

Pumping systems

A system, initially at atmospheric pressure, is first evacuated by a medium-vacuum pump (forepump) until a pressure is reached where a high-vacuum pump becomes effective and can be used for final evacuation to the desired pressure.

The most common forepumps are

* mechanical pumps (rotary pumps)

and the usual high-vacuum pumps are

* diffusion pumps

* turbomolecularpumps

In ultra-high vacuum applications, specific pumps are used as

* cryopumps

*sputter-ion pumps

Mechanical pumps (1)

Most mechanical vacuum pumps are of rotary type and are sealed with oil. A small quantity of gas from the system is isolated, compressed and discharged to the atmosphere with each rotation of the piston or vane. These pumps have intrinsic speedsS0ranging from 5·10-4to 0.35 m3s-1.

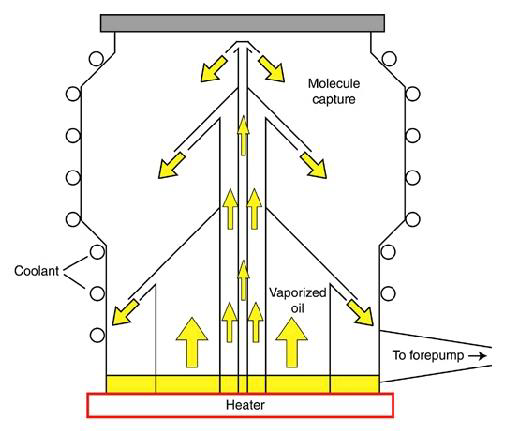

Diffusion pumps :

A diffusion pump utilizes a vapour jet to impart increased momentum to the gas molecules being removed from the system. The gas molecules are forced out of mouth of the discharge into a mechanical forepump.

The pump liquid is heated in the boiler and its vapour is carried to a multistage nozzle from which it is ejected as a high-velocity jet directed downwards and towards the wall of the pump. The jet expands and finally strikes the water-cooled wall, the working fluid condenses and flows down the wall back to the boiler.

The vapour jet collides with the residual gas molecules, which are driven toward the bottom of the pump and compressed at the exit side.Several jets working in series serve to enhance the pumping action.

The vapour jet collides with the residual gas molecules, which are driven toward the bottom of the pump and compressed at the exit side.Several jets working in series serve to enhance the pumping action.

Diffusion pumps operate under molecular flow regime, therefore a mechanical forepumpis required.

A serious problem associated with diffusion pumps is the backstreamingof the working fluid (typically silicone oil) into the chamber.

In order to minimize backstreaming, cold baffles are used between the pump and the vacuum chamber. The surfaces are generally cooled by liquid N2and vapours condense on them.

Diffusion pumps are capable of attaining pressures lower than 10-6mbar without traps.

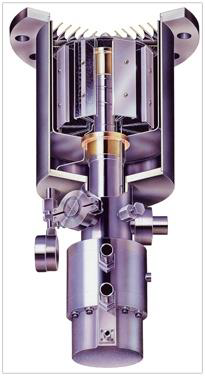

Turbo molecularpumps:

In turbo molecularpumps, the gas molecules are imparted a velocity by momentum transfer from a fast-moving solid surface.

These pumps consist of many rotor/stator stages mounted in series (rotor speed of 20,000 to 30,000 rpm).

Gas captured by the upper stages is transferred to the lower stages where it is successively compressed to the level of the fore-vacuum pressure.

Turbomolecularpumps (2)

The compression ratio varies exponentially with the product of the tangential rotor speed and square root of the molecular weight of the gas. Typical maximum compression ratios for hydrocarbons, N2and H2are 1010, 109and 103, respectively. Conversely, the pumping speed is weakly dependent on the molecular mass of the pumped gas, because of the compensating effect given by higher arrival rate (conductance) of light gases.

An important consequence of the very high compression ratio is that oil back streaming from lubricated bearings is reduced to very low levels. Magnetically levitated bearings can also be used.

Turbomolecularpumps are expensive, but are increasingly employed in thin-film deposition and characterization equipment.

Typical characteristics include pumping speeds of 103litres/s and ultimate pressures of 10-10mbar.

Cryopumps::

Cryogenic pumps are capable of creating very clean vacuum in the high-vacuum or ultrahigh-vacuum range (10-3to 10-10mbar).

These pumps rely on the condensation of vapour molecules on surfaces cooled below 120 K.

Cryopumpsfor UHV have panels that are cooled to low temperature (20 K) by closed-cycle refrigerators. These surfaces are surrounded by shields cooled by liquid nitrogen, otherwise the radiant heat load should be too large.

In addition, an initial low pressure (~10-3mbar) is required, in order to reduce the thermal load on the refrigerant and to avoid the accumulation of a thick ice layer on the cryopanels.

Cryopumpsare regenerated by allowing them to warm up or baking at higher temperature.

All gases, except He, condense to form a solid phase at sufficiently low temperatures (cryocondensation). A temperature of 20 K is low enough to achieve UHV conditions with all gases, except He, Ne and H2.

The effectiveness of a cryopumpis increased very significantly by cryosorption: a gas is adsorbed on a cooled solid at temperatures higher than the boiling point of the gas itself. Adsorbantswith high surface area, like activated charcoal or molecular sieves, are commonly used.

All gases, except He, condense to form a solid phase at sufficiently low temperatures (cryocondensation). A temperature of 20 K is low enough to achieve UHV conditions with all gases, except He, Ne and H2.

The effectiveness of a cryopumpis increased very significantly by cryosorption: a gas is adsorbed on a cooled solid at temperatures higher than the boiling point of the gas itself. Adsorbantswith high surface area, like activated charcoal or molecular sieves, are commonly used.

Source:Mattox D.M., Handbook of Physical Vapour Deposition (PVD) processing, Noyes Publications, 1998.

Congratulations @bharathsg! You have received a personal award!

Click on the badge to view your Board of Honor.

Do not miss the last post from @steemitboard:

SteemitBoard World Cup Contest - Belgium vs Japan

Participate in the SteemitBoard World Cup Contest!

Collect World Cup badges and win free SBD

Support the Gold Sponsors of the contest: @good-karma and @lukestokes