FORGING AND FORGING - INTERESTING FACTS AND NOT ONLY

One of the oldest arts of metal processing is forging. With its help, people created iron products, necessary and facilitating the life of distant times. Fused tools and tools were particularly appreciated because of their strength and durability. Found in Central Russia, steel samples of the V-VI century AD speak of the excellent professionalism of forge masters.

"The excavated artifacts are not only masterfully made, but also skilfully decorated. This is evidenced by the finds of remains of kitchen utensils and wondrous decorations"

APPEARANCE OF IRON

The first materials used in forging were natural gold and copper nuggets. Later, experimenting with alloys, smiths smelted bronze. An important discovery and breakthrough in science and weaponry was the treatment of meteoric iron. The alloy of iron and carbon gave a great perspective in the development of many industries, from agriculture to metalworking.

"Steel items from ancient times people used in their home life, and in other areas of activity. Therefore, the blacksmith's craft was so highly respected in society. It's not for nothing that folk wisdom says: "The smith is a father to all affairs."

GOD-SMITHS

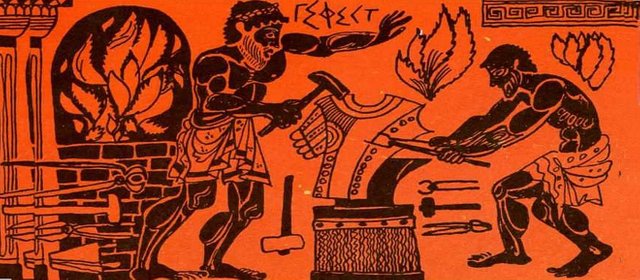

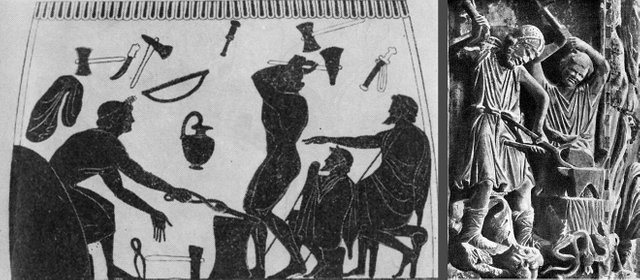

From the early pagan times, the gods dominated the hierarchy of gods, the demigods-smiths or their descendants associated with the elements of fire and the process of iron processing. We know such patrons of the blacksmith's trade: Hephaestus is the Greek god, Thor is Scandinavian, Woland is European. In popular beliefs there are blacksmiths - sorcerers, shamans and lords of fire elements.

In Ancient Russia, honor Svarog - the god-blacksmith sent to Earth for the construction of the human universe. Assistant blacksmiths were priests of Svarog. They are endowed in the historical epic with positive characteristics of heroes: an unprecedented force, excellent courage and incredible endurance. Forged things were very appreciated, hence the great authority of the blacksmith in the community and the state of the early period derives.

THE MYSTERY OF THE TRANSFORMATION OF THE Marsh Ore

The secrets of ore mining were classified and accessible to a narrow circle, so they became conglomerate and rumors. Mythicalness was added to the use of meteorite iron in smithies. He was given a special unearthly origin. The nebulae were driven by artisans as well. Actions with "unearthly material" were conducted in strict secrecy and were available to the units. Even the fellow villagers were afraid to show interest in what is happening in the workshops because of fear and superstitious prejudices.

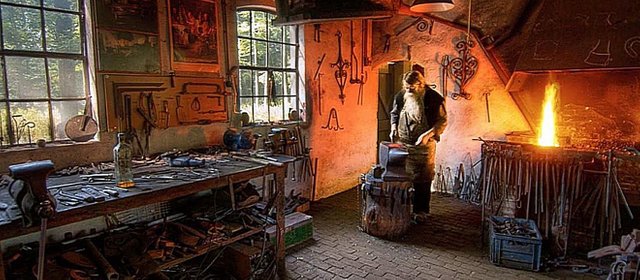

Forges have always been erected on the outskirts of the settlement, due to fire safety, as well as near ore and coal reserves. They were built in the ground. There were no windows in the room. In such a construction it is convenient to maintain the desired temperature. Semi-darkness helped the master "by eye" to determine the level of metal heating, which definitely influenced the quality of forged elements.

TEMPERATURE MODE

Warm up the iron needed to a temperature of 800-1200 C. Is this small or a lot? Now such figures do not surprise anyone. But in the old days, to achieve such temperatures it was necessary to spend more than one hour. Steel got very heavy work. Blacksmiths-apprentices manually inflated leather fur in a melting furnace, and today for these purposes a pyrometer or thermocouples are used.

MYTHS ABOUT MASTERS-SMITHS

Considering the paintings about smithies and forge, we usually see the image of a hardened hero with a massive sledgehammer in his hands. The bared torso is covered with a leather apron, strong muscles are visible under it. Burning sparks fly out from under the hammer. So pathetic is the representative of the blacksmith profession in the illustrations. In fact, a person who has been forging for many years, often wiry and dried by the heat of the day.

The master supervised the process of forging - he held the handbrake and gave orders to the apprentice when and where to beat on the hot workpiece. The entire cycle should occur quickly and smoothly, until the iron has cooled. Constant blows not only dried the hands of the hammer, but also led to diseases and deformities of the joints. All this is the cost of working in a hot shop. The smith's work was harmful and dangerous for health. But despite this, getting into the disciples to the artisan blacksmith was a huge success.