Integrated Subassemblies for 800G/1.6T Transceivers

With the rapid development of artificial intelligence (AI) and large language models (LLMs), global data centers and AI computing clusters are experiencing an unprecedented demand for higher data transmission rates. Optical transceiver speeds are scaling from 100 Gbps to 400 Gbps, quickly advancing to 800 Gbps, and further toward 1.6 Tbps and beyond. This evolution not only enhances the transmission capacity of optical transceivers but also places greater demands on optical interconnect subassemblies in terms of reliability, coupling efficiency, and compactness.

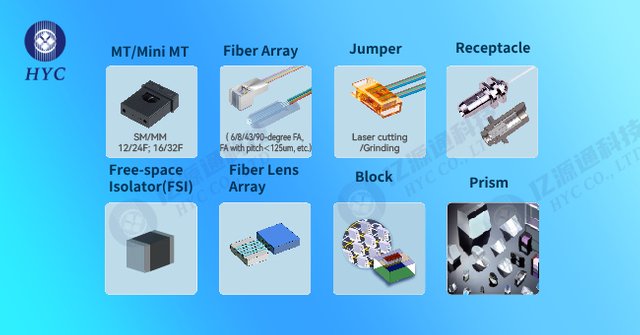

Based on seven core technology platforms, HYC offers flexible customizable integrated subassemblies for 800G/1.6T, Silicon Photonics, optical transceivers.

- Eight basic components

HYC is committed to developing eight foundational component platforms to meet the diverse integration needs of optical transceivers. These platforms include MT/Mini MT, Jumper (Laser cutting), Fiber Array (FA), Receptacle, Free-Space Isolator (FSI), Fiber Lens Array, Block, and Prism. These components serve as the building blocks for various customized subassembly solutions, such as 2×MT-3×FA, FA + Isolator, and FA + Lens array, and more.

- Parallel optics subassemblies for DR/PSM transceivers

Two main transmission solutions are used in optical transceivers: parallel optics and WDM optics. Parallel optics are preferred for short-reach applications due to their cost-effectiveness, while WDM is widely adopted for medium- to long-distance optical communications and interconnections in data centers.

Parallel optical modules, like SR4, SR8, PSM4, and DR8, utilize multiple data channels to transmit data simultaneously, increasing bandwidth and throughput. MT-FA (MT Fiber Array) and MT-Jumper (MT Patch Cord) are indeed widely used in parallel optical modules, particularly for high-speed data transmission applications like 400G and 800G. MT-FA and MT-Jumper are key components that facilitate efficient and compact parallel optical connections within these modules.

Depending on the module’s structure, components like isolators (FSI) and lens arrays can be integrated into the FA or Receptacle. For example, an MT-FA combined with a lens array is often used at the Rx (receiver) end to focus light effectively into the photodetector. This configuration improves coupling efficiency, simplifies optical packaging, reduces processing steps, and lowers overall manufacturing costs. MT-FA with Isolator integrates a fiber array with an isolator to prevent signal reflections and ensure unidirectional light transmission.

- WDM optics subassemblies for FR/LR transceivers

There are two main technologies used for implementing WDM optics technology in optical modules: Thin-Film Filters (TFF), based on free-space optics, and Arrayed Waveguide Grating (AWG), based on Planar Light Circuit (PLC) technology, as well as Echelle Diffraction Grating (EDG) and cascaded Mach-Zehnder Interferometer (MZI) arrays. Among these, TFF (using the Z-Block technology) and AWG are the most commonly used and representative MUX/DEMUX subcomponents.

Z-block-based assemblies integrate various functional components of optical transceivers, including the Receptacle, Collimator, Z-block, Lens Array, and Prism. This significantly simplifies the transceiver assembly process, enhances optical alignment, and improves production efficiency.

About HYC Co., Ltd

Founded in 2000, HYC is a leading global manufacturer of innovative and reliable passive optical components. HYC designs, develops, manufactures, and sells a comprehensive line of passive optical devices that enables 5G/6G, data center, data communication, FTTH, aeronautical communication networks.

.jpg)

.jpg)