Our Collage Project "Brick Molder Compactor"

I. SUMMARY

Bricks play an important role in our society. All through the years, it has been the most important thing that harnesses the people’s need for shelter. It has been use as pavers and wall decorative. And some houses used it for walling. Instead of using hollow blocks, bricks are found to be the best substitute for the construction of walls, for it is cheaper when it comes to the totality of the whole wall construction. To make the wall stronger and reliable, the present group incorporated a frog not exceeding 20% of the brick volume on the upper part of the brick on a stretcher position. No reinforcement bases are needed; the frog on the brick can hold enough and stabilize the wall with the aid of a grout.

Most bricks are made out of clay and fired in a kiln and some are made out of ordinary sand and cement. Based from previous research, they’ve found out that there is an alternative raw material to be mix with sand and cement in making bricks. It is banana fiber. It is also a good choice for it is abundant in the Philippines. Before arriving on the best proportion banana fiber, water, cement and sand, experimentation must be done to achieve strength-to-cost brick production. So the present group is also entitled in repairing a particular machine previously manufactured by a group of Silliman students that could mass produce the brick designed with a four bar linkage presser, four molds with holes on the side, banana fiber, cement, sand and water and a vibrator for proper distribution and compaction of the mixture with a minimum of three operators.

II. INTRODUCTION

Bricks are ceramic materials made usually form clay and other minerals molded into solid or hollow blocks, for use in construction of walls, floors, pavements and other structures. Most bricks can be made from different clay types which distinguish the color of the brick product. It may be dried using the heat from the sun or from other heating equipment like furnace or oven.

Building bricks are inexpensive building materials. Their low cost and structural versatility have led to their wide use for construction. These are made in sizes that can be lifted by hand since bricks are laid manually during construction. Even before, bricks were known to be the main building material of ancient civilizations like Mesopotamia, Sumeria, Babylonia and Palestine among others. For a fact, even the Great Wall of China was built with the said material. For thousands of years, good quality bricks have been used made out of very little and simple equipment. In the Philippines, even in our locality, usually bricks are used for pavements and wall decorative. Based on Dr. Benjamin Tobias’s point of view, solid bricks could be used as a substitute for hollow blocks for walling. And he added that it may result to a much cheaper and durable wall construction.

Nowadays, there are variations of bricks made from clay to bricks made from cement and other mixture. Several companies have already engaged themselves in manufacturing bricks made of sand and cement with the proper amount of water. Considering the present financial status of most Filipinos, most are becoming practical, thus seeing to it that the material that they are buying is relatively cheaper but safe and durable enough. As an answer to the call, the group with the help of Dr. Tobias, decided to use banana fiber which can be found anywhere to be mixed with the sand and cement.

Hypothesis

Good Quality bricks can be produced out of banana fiber, sand and cement.Subsidiary Question

What kind of standard mechanical property behavior of bricks should be investigated?

What is the appropriate banana fiber, cement, sand and water proportion?

Could it compete with hollow blocks based strength-to-cost ratio?

Aim

The aim of the project is to refabricate a mechanism that would be able to bring into being good quality bricks and to establish a reputation that the bricks produced can be used in walling houses.The main aim of this project proposal is to refabricate a mechanism from a previous design that would produce quality bricks with specific design parameters listed below.

The bricks to be produced incorporate cement, sand and banana fiber as main components of the mixture and, considering its strength-to-cost proportion.

Design Parameters

Bricks must have smooth surface finished.

Bricks are compacted to be made onto a high-density material.

Frog is present in the design brick to incorporate mortar during construction of wall for houses.

Bricks produced can be sold commercially and competitively in the market.

- Significance of the Proposal Work

The project is intended to help every Filipino unearth an alternative material to be used in constructing their house walls which is more cost-effective compared to the existing one known as the hollow blocks.

- Review of Relevant Research and Theory

Practicality is what the people believe nowadays. Especially in this time of

Economic crisis, people go for low-cost materials rather than those expensive ones. Under these circumstances, the researchers were geared on helping solve this problem even just on the matter of bricks used for walls.

In the past, there had been actions with regards to the making of construction materials for walling purposes. As time went on, modifications of these designs were made, and to the extent of making brick-molding mechanism. Silliman University College of Engineering had projects on molding construction materials such as hollow bricks done by past students. The first brick mechanism designed by Silliman University engineering students was a modification of the hollow brick mechanism. Their mechanism produces bricks with a hole used for walling. The bricks they produced had a 50-50 mixture of silica and cement. The mechanism is relatively simple. It is made of steel plates and steel bars. The mechanism had two molds positioned in a vertical manner. Once the mixture is placed in the molds and compacted, a lever about 5-feet is pulled to activate a linkage system to lift the molded bricks. And they also concluded in their paper that the design was found to be defective and needed some proper modifications. The bricks were ineffective because the group said that they have never experimented and tested some samples of silica, cement and water proportions. In the present researcher’s case,1:3is the mixture of the bricks but can still be improved for it is our basis for further developments. The size of the bricks is based on the standard format sizes of modular bricks.

Ryan, W. G. (1992). Australian Concrete Technology. Australia: Longman Cheshire Pty. Ltd.

So the researchers, with the help of our adviser decided to produce a solid bricks which has a frog at the top on a stretcher position because the frog serves as a stabilizer without incorporating reinforcement bars so maybe it is more economical compared to a hollow one.

There are a lot of advantages of bricks over hollow blocks aside from its being economically practical to use. Hollow blocks may be cheaper when it comes to individual price, but in totality, it comes out to be more expensive because of the process it takes like the finishing touches it requires to look attractive and presentable, the added hefty cement placed in its large holes with bars for stability, and it is weaker than bricks when it comes to compactness and durability. Bricks on the other hand, maybe slightly higher in individual price, but still turns out to be cheaper because varying bonds can directly be designed in the appearance of the wall, and only a small amount of cement is needed to stabilize the wall because of its smaller holes and compactness.

“Cement” Microsoft Encarta Reference Library 2010

The bricks to be produced are employing Portland cement, banana fiber and sand. We employed Portland cement due to its high drying capabilities as well as strength. Cement is one of the most essential materials in the construction of any structure such as buildings, roads, dams, and piers. It is a flour-like powder which varies in color from greenish gray to brownish gray. Cement is a basic industry—it uses basic (naturally occurring) materials. It is the world’s most important building product. Cement goes back as far as the Roman empire. They made kiln dried bricks and held them together with a lime and volcanic ash mixture, which is similar to present day pozzolanic cement.Modern cement is called Portland Cement and has its origins beginning in the early 19th century in England. Now it’s one of the highest commodities used per person in the world. Portland cement is classified into 5 main types—normal or ordinary, modified or moderate-heat-of hardening and sulfate-resisting, high-early-strength, low-heat, and sulfate-resistant. There are four major chemical elements in Portland cement classified as oxides, these include—lime, silica, alumina, and iron. They constitute more than 90% of the total composition of the clinker. Portland cement is a mixture of three parts of limy material in the form of limestone and one part clayish material in the form of shale. Portland cement is obtained by pulverizing the clinker consisting essentially of calcium silicates.

Other component of the designed bricks is the banana fiber. The abundance of this material can be addressed to tropical countries such as the Philippines. Natural fibers present important advantages such as low density, appropriate stiffness and mechanical properties and high disposability and renewability. Moreover, they are recyclable and biodegradable. There has been lot of research on use of natural fibers in reinforcements. Banana fiber, a ligno-cellulosic fiber, obtained from the pseudo-stem of banana plant (Musa sepientum), is a vast fiber with relatively good mechanical properties. [3]

The strength testing of the concrete involves drop tests only as the bricks produced are not load bearing materials as told byour adviser, Dr. Benjamin Tobias.

http://www.jeffjournal.org/papers/Volume3/Mukhopadhyay3.2.pdf

III. METHODOLOGY

First a frog plates are placed under the molder boxes. The fresh molded bricks are placed on this plate after it is being pressed and the mold is being ejected. The machine has a table above the motor and parallel to the molders and it is where the mixture is placed and then pushed to the four molders. Best proportion of the bricks is to be achieved through experimentation. And some considerations of other mixture quantities are still open to be tested. As the motor runs and creates a vibratory motion of the molder due to the counter weight that is turning the mixture then fills up the mold boxes much easily and therefore pressing of the mixture is much more efficient and with the help of the top cover and a hydraulic jack. After the filling process the motor is switch off and the molds are ejected using a lever connected to a four-bar linked that will push the molds on a vertical position. The frog plates together with the formed bricks is lifted outside of the molder and then transfer to the curing area where it will be cured under the heat of the sun. The new sets of frog plates are then being removed by heating its edges and the product is piled out.

The designed bricks are to be used for walling of average houses. It is to be laid in a stretcher position overlapping from one to the other.

- Design

A. Molding Design

- starting mixture must be based from experimentation.

- the mold is designed based on standard size brick of typical brick size in the

U.S. (4” x 2 2/4” x 8”). - holes are incorporated at the sides to let excess air and water in the mixture to escape and prevent cavitations of the product.

- many sets of frog plates (see fig. 4) are incorporated as an accessory of the molder. Depending on the number of frog plates will also determine how many bricks can be made for this will only be removed if the bricks are hard enough not to be broken when the plates are to be removed.

- the mold should be tapered at least 1mm. on all sides to minimize friction.

- 4 bricks can be molded at a time for easy and much faster operation.

B. Design of Fabricating Set-up

- the molders must be at least to the waistline of an average person for the convenience when operation of the machine is done.

- the molder must vibrate strong enough to ensure a good compact mixture.

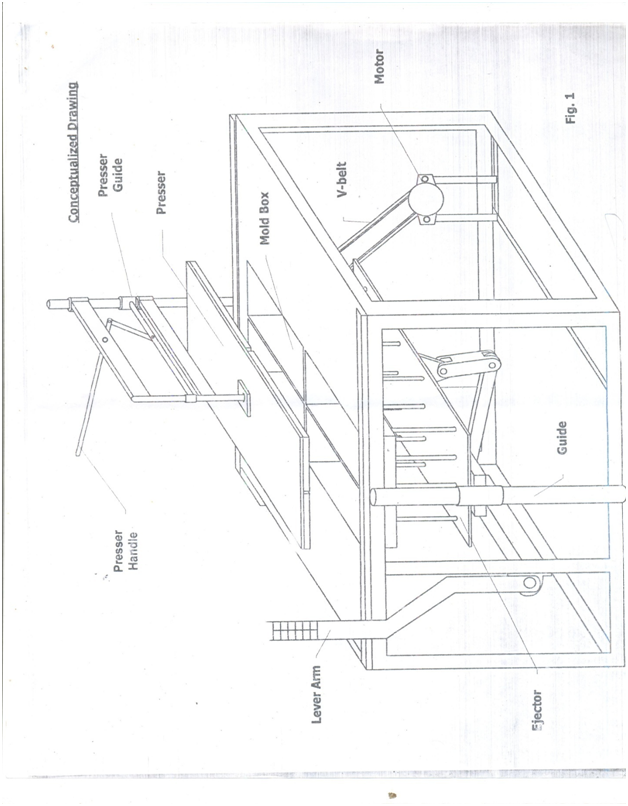

- a presser ( see fig. 1 ) with the help of a hydraulic jack must be used for compacting process.

- 3 workers are needed every operation (operator, mixer /handler, handler).

- the molder has a table to place the mixture into it when operation is on process.

The design as seen in Figure 1 is to be equipped with a vibrator system in such a way that the whole mechanism or the mold boxes will shudder so that it will ensure equal compaction and distribution of the mixture to all sides of the mold. And to address one design parameter that is the brick must be smooth surface finish and that it is of high density material holes are incorporated at the sides of the mold in order for the excess air and water to escape and prevents any cavitations to form within the bricks. The new design is designed to have a vertical ejection so that the bricks that will be form will be of precise size, not like the horizontal ejection the dimensions of the bricks may vary due to the movement caused by the molder walls where it is the walls that is used to push the bricks out. There will be 4 bricks form at the time for this will ensure faster and easy operation of the molder since there will only be 3 workers for this mold (the operator, the handler at the right side and the handler/ mixer at the left side).

The molder is equipped with a table where the mixture is to be put into. The mixture is then pushed to the mold boxes. There will also be frog plates that will be used in order to make the frog of the bricks and helps it ejects the mold. The group could then precede the design and tests on different mixture proportions that would provide good quality product using ASTM standards or British standards.

- Performance Characterization

Initial investigation of the constituent’s proportion has been done in order to rationalize the mixture of banana fibers, cement and water.

- Sample Preparation

The group was able to make some brick samples with varying composition as to determine the appropriate proportion of banana fibers, cement and water and to find out if the product has an acceptable drop test result with respect to the economy for walling purposes as showed below.

These are the following steps in preparation of the samples. First the researchers started filtering the sand (by using finest screen available in market). Then the filtered sand were washed to drain the dirt. Then the researchers made frog plates of plywood material. Next the researchers cut out fibers from the banana trunks that were processed by the Fibering Machine of Dr. Benjamin Tobias, our adviser. The group and the adviser have decided to have two kinds of banana fibers; (1) non-particulate and (2) particulate as to obtain the best possible combination of the bricks. The non-particulate fibers are of about 1-2 cm in length while the particulate fibers are of about 1-2mm in length. Then the mixing can now be done for all materials needed are ready.

- Operating Procedure

Proper operation is very important in machines. It is one way of serving time as well as providing operator’s safety.

4.1 Mixing

The first operating procedure is mixing, based from the advisedproportion of sand and cement; banana fiber is mixed with cement and water. The researchers first mixed the cement and sand. Then the researchers added the desired amount and type of fiber that was cut out before the mixing. For the fiber that was based from the volume of the mixture, the researchers used a measuring cup in measuring the desired volume for the fiber to be added. While for the weight based fiber, the researchers used a small weighing scale to measure the desired weight of the fibers to be added to the mixture. After it is mixed, water is then added to the mixture and then now it is placed in the machine’s table for it to be pushed to the molds.

4.2 Filling

When the mixture is in place, it is then pushed to its right location on the mould boxes thus filling it with its initial amount.

4.3 Vibrating

The next step is to shake the mold boxes using a vibrator to assure homogeneity of the mixture. When the mould boxes are not filled enough, the remaining mixture must be added.

4.4 Pressing

After filling the mold boxes, the motor of the vibrator is turned off; then mixture is then pressed by the top cover with the aid of a hydraulic jack to add compactness to the mixture.

4.5 Ejecting

When pressing is done, the molded mixture is then ejected with the frog plate and to be placed to the curing area.

4.6 Refilling

After ejection method, refilling is done by following the whole operation procedure.

- Mechanical Property Test

From the structural viewpoint, the main classification of a brick is according to its compressive strength and also its compactness. The strength must be maintained for the required design life. So the group is entitled to test their sample bricks to be able to determine the strength capability against the bricks compositions.

The researchers only tested the bricks’ compactness by conducting a drop test, for bricks are not load bearing so compressive strength test is not needed as advised by Dr. Benjamin Tobias, our adviser. The following is the table consisting of the different combinations of the bricks and its drop test results. The 1:3 proportion of the sand and cement, amount of water used in the mixture, the time where the mixture is vibrated, and the curing period of the bricks were held constant by the researchers. The researchers had 10 samples of bricks in each combination, 5 of them was tested by drop test in order to obtain data as to what height will the bricks start to crack. And the other 5 was dropped in order to obtain data as to what height would the bricks break.

If you have questions and comments, feel free to ask me and leave a comment.

Have a nice dayeveryone!

-Ren

Congratulations @rmebelgs! You have received a personal award!

Click on the badge to view your Board of Honor.

Do not miss the last post from @steemitboard:

Congratulations @rmebelgs! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Do not miss the last post from @steemitboard:

Vote for @Steemitboard as a witness to get one more award and increased upvotes!