Lobe Pump Solutions: Enhancing Efficiency and Hygiene in Fluid Processing

A lobe pump is a high-performance, positive displacement pump known for its gentle handling, sanitary design, and ability to transfer a wide range of fluids efficiently. Its unique mechanical action and construction make it a preferred choice in demanding industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and biotechnology. With growing emphasis on cleanliness, consistency, and energy-efficient operation, the lobe pump has become an essential component in modern processing systems. Its ability to maintain product integrity while operating under various conditions sets it apart as a reliable and flexible solution.

How a Lobe Pump Operates

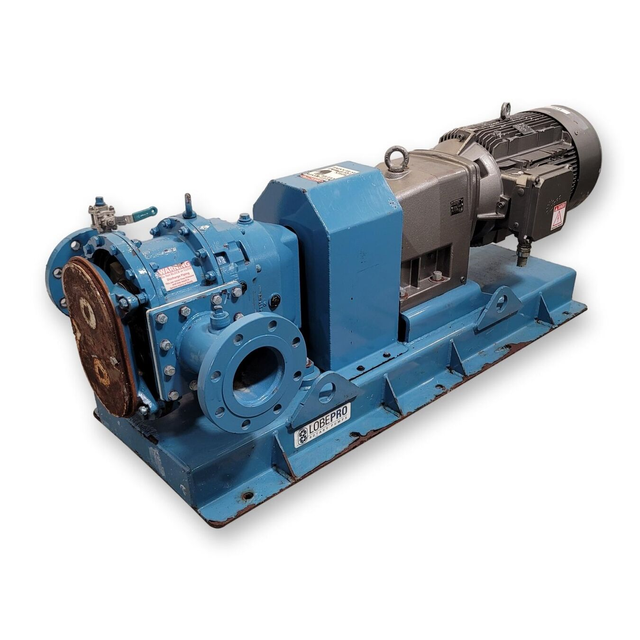

At the heart of a lobe pump is the rotation of two or more interlocking lobes mounted on parallel shafts inside a casing. As the lobes rotate in opposite directions, they create a vacuum on the suction side, drawing fluid into the pump chamber. The fluid is then carried around the inner walls of the casing in cavities formed between the lobes and the housing. Once it reaches the discharge side, the cavities collapse, pushing the fluid out in a continuous and smooth flow.

A major advantage of the lobe pump’s design is that the lobes do not touch each other or the casing. This non-contact operation minimizes wear and tear and eliminates the risk of product contamination. The precision of the movement ensures consistent flow without causing turbulence or shear, which is essential for maintaining the quality of delicate or high-viscosity fluids.

Versatile Applications Across Industries

The versatility of a lobe pump makes it indispensable across many processing industries. In food and beverage manufacturing, it is widely used to handle products like dairy, syrups, sauces, fruit fillings, and soft solids. The pump’s gentle action prevents damage to ingredients, preserving flavor, texture, and appearance. Its hygienic design also helps comply with food safety regulations and makes it suitable for clean-in-place (CIP) processes.

In pharmaceutical and biotech applications, a lobe pump is employed to transfer sterile fluids, active pharmaceutical ingredients (APIs), and sensitive biological materials. Its ability to operate in sterile environments while meeting stringent hygiene requirements is critical. The stainless steel construction and availability of aseptic sealing options further support use in regulated, high-purity environments.

In the chemical industry, the lobe pump handles a variety of corrosive, abrasive, and viscous substances, such as adhesives, slurries, paints, and solvents. The robust build and chemical-resistant materials make it suitable for harsh processing conditions. In cosmetics and personal care manufacturing, the pump efficiently transfers creams, gels, lotions, and emulsions without separating or damaging the product.

Why Choose a Lobe Pump?

A standout feature of a lobe pump is its low-shear pumping action, which is particularly beneficial for fluids containing solids or shear-sensitive compounds. Unlike high-speed centrifugal pumps, which can degrade product quality, a lobe pump maintains fluid integrity throughout the transfer process. This is especially important when handling delicate food products or pharmaceutical solutions.

The pump’s self-priming ability enhances operational flexibility. It can draw fluid into the system even when the suction line is empty or when air is present, making it suitable for intermittent operations or where priming the pump manually is impractical. This also reduces downtime and improves startup efficiency.

Ease of maintenance is another core benefit. Most lobe pump models are designed for quick disassembly and cleaning, allowing technicians to access internal components without removing the pump from the system. This design saves time and supports compliance with sanitary protocols, especially in clean environments where frequent maintenance is necessary.

Lobe pumps are also highly energy-efficient. Their mechanical design ensures minimal slippage and consistent flow, even under variable pressure or viscosity conditions. This efficiency translates into lower energy costs over time and supports sustainability goals in energy-conscious industries.

Selecting the Right Lobe Pump

To get the most out of a lobe pump, it’s important to match the pump’s configuration with the specific characteristics of the application. Key considerations include the viscosity of the fluid, the presence of solids or abrasives, operating temperature, and the chemical composition of the fluid. These factors influence the selection of materials, lobe shape, and sealing technology.

Flow rate and pressure requirements also play a crucial role. A lobe pump is capable of delivering consistent performance across a wide range of conditions, but selecting the right size and model ensures maximum efficiency. Some applications may require specialized features such as steam jackets, hygienic connections, or aseptic barriers to meet process-specific needs.

Compatibility with cleaning and sterilization procedures is another important factor. Pumps used in regulated environments must support CIP or SIP systems to maintain hygiene standards. A lobe pump with sanitary certifications and polished internal surfaces is ideal for such environments.

Evolving Technology in Lobe Pumps

Manufacturers like Ace Lobe Pump are continuously innovating to enhance the functionality and performance of lobe pumps. Advances in rotor design, precision machining, and sealing technologies have expanded the capabilities of these pumps. Today’s models offer higher efficiency, improved durability, and greater adaptability across applications.

Modern lobe pumps are increasingly integrated with smart technologies. Sensors and digital controllers enable real-time monitoring of pump conditions such as flow rate, pressure, and temperature. These systems allow for predictive maintenance and reduce the risk of unplanned downtime. Automated alerts and diagnostics make it easier to manage operations remotely and increase process reliability.

Customization is another area of growth. Companies now have the flexibility to configure their pumps based on specific process needs. Whether it’s a compact model for space-limited installations or a high-capacity unit for industrial production, manufacturers like Ace Lobe Pump provide tailored solutions to meet diverse operational requirements.

Conclusion

A lobe pump offers an unmatched combination of gentle handling, energy efficiency, hygiene, and durability, making it a critical tool in modern fluid processing. Its unique mechanical design allows it to manage a wide range of fluids—from delicate food mixtures to corrosive chemicals—without compromising product quality or process performance.

As industries continue to demand smarter, cleaner, and more adaptable fluid handling systems, the lobe pump remains at the forefront of innovation. Companies looking to upgrade their pumping systems or design new process lines can rely on trusted manufacturers like Ace Lobe Pump to deliver advanced, customizable solutions built for long-term success. Whether the goal is hygiene, efficiency, or reliability, the lobe pump continues to set the standard in industrial fluid transfer.