Key Factors Driving the Adoption of Liquid Applied Roofing Solutions

The liquid applied roofing market is experiencing significant growth as construction industries worldwide seek durable, cost-effective, and sustainable roofing solutions. These coatings provide seamless protection against water infiltration, UV radiation, and harsh weather conditions, making them a preferred choice for commercial, residential, and industrial buildings. Several key factors are driving the increasing adoption of liquid applied roofing solutions in 2024 and beyond.

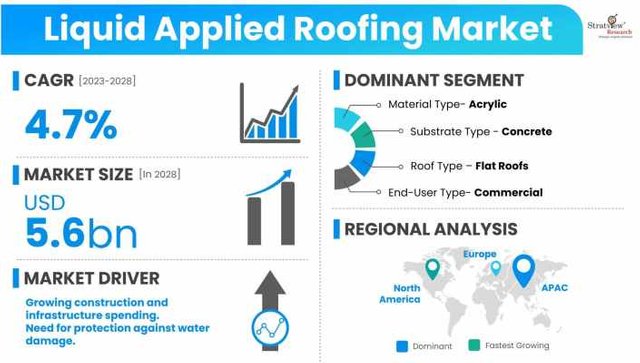

According to Stratview Research, the liquid applied roofing market is estimated to grow at a healthy CAGR of 4.7% during 2023-2028 to reach USD 5.6 billion in 2028.

1. Superior Waterproofing and Seamless Protection

One of the primary reasons for the rising adoption of liquid applied roofing solutions is their seamless waterproofing capabilities. Unlike traditional roofing materials that have joints and seams prone to leaks, liquid coatings form a continuous membrane, preventing water penetration and ensuring long-term protection against moisture damage.

2. Cost-Effective Roof Maintenance and Restoration

Building owners and facility managers are increasingly opting for liquid applied roofing to extend the lifespan of existing roofs without costly replacements. These coatings allow for efficient restoration of aging roofs, reducing labor, material, and disposal costs. Their ability to be applied over various roofing substrates makes them a versatile and budget-friendly option.

3. Energy Efficiency and Sustainability

With growing concerns about climate change and energy consumption, liquid applied roofing solutions are gaining popularity for their reflective properties. Cool roof coatings, often made of acrylic or silicone, help reduce heat absorption, lowering indoor temperatures and cutting energy costs for air conditioning. Additionally, low-VOC and eco-friendly formulations align with green building standards and sustainability goals.

4. Adaptability to Complex Roof Designs

Unlike traditional roofing materials, which may require extensive modifications, liquid coatings can be applied to irregular surfaces, slopes, and hard-to-reach areas. This flexibility makes them ideal for modern architectural designs and roof structures with multiple penetrations such as vents, HVAC units, and skylights.

5. Regulatory Compliance and Green Building Standards

Government regulations and industry standards promoting energy-efficient and eco-friendly construction are influencing the demand for liquid applied roofing solutions. Many formulations comply with LEED (Leadership in Energy and Environmental Design) standards, encouraging their use in sustainable construction projects.

6. Rapid Application and Minimal Disruption

Liquid applied roofing systems are easy to install, requiring minimal downtime compared to traditional roofing methods. Their quick curing times and compatibility with existing substrates make them an excellent solution for projects where business continuity and minimal disruption are essential.

Conclusion

The adoption of liquid applied roofing solutions is being driven by their durability, cost-effectiveness, energy efficiency, and sustainability. As industries shift towards smart, eco-friendly, and long-lasting construction materials, liquid applied roofing is set to play a crucial role in the future of roofing technology.