Turning my Garage into a Workshop — Part 3b: SawStop® Assembly

Eighteen days ago I pictoralised stage one of my table saw construction. Let's get this thing finished!

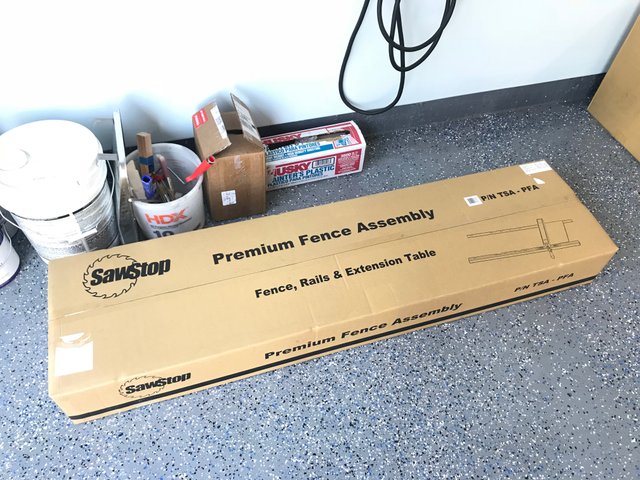

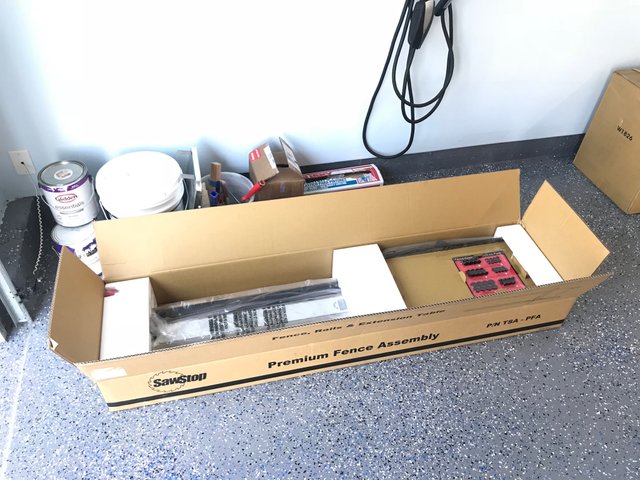

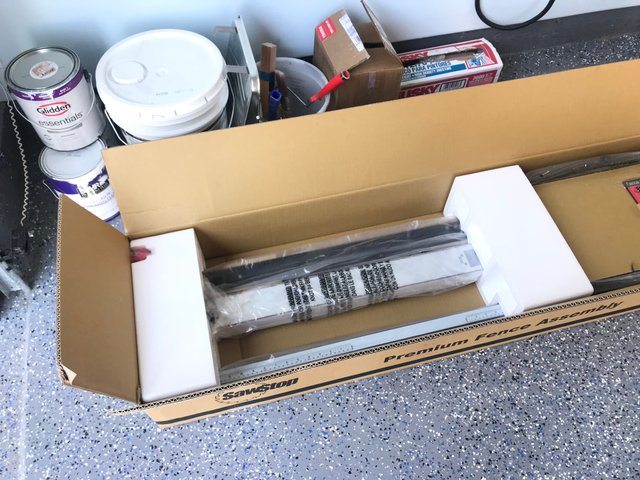

Rails

Although this says "Premium", it is the base option. The upgrade is called "T-Glide" but I'd need a longer extension table for that, and my space is at a "premium".

Hey, Georgie, you wanna balloon⸮

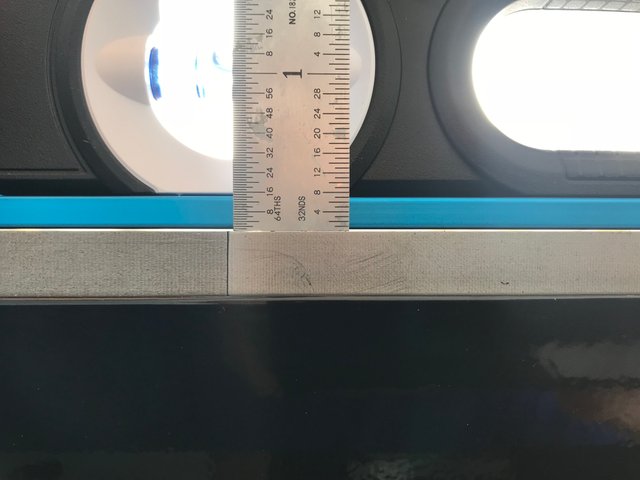

I'm using this as a level because I don't have a spirit level...

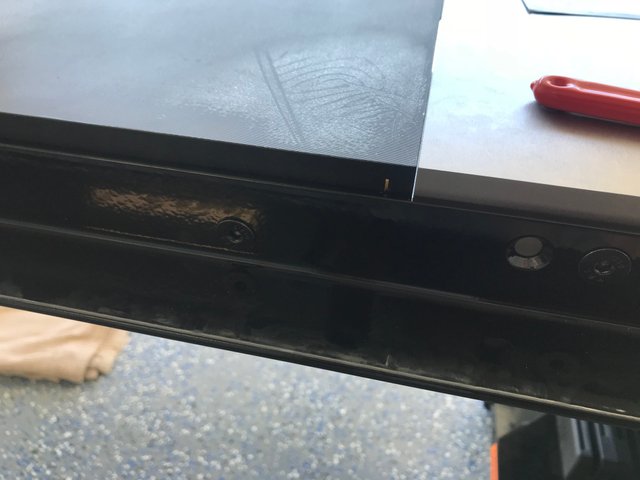

There's a big gap here. I put nearly my whole weight on the wing to try and straighten it. Will have to come back to this later.

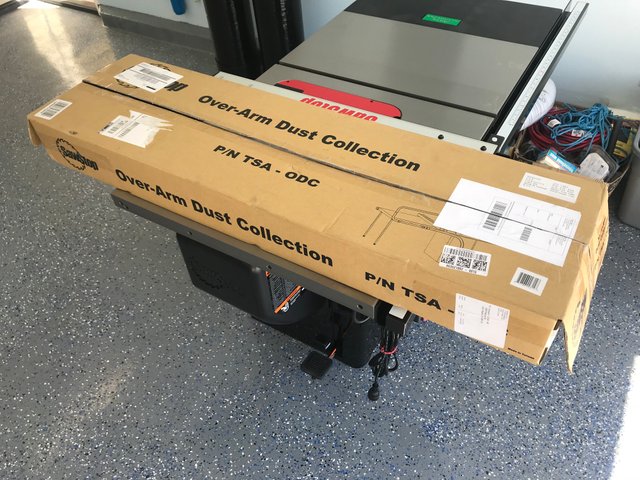

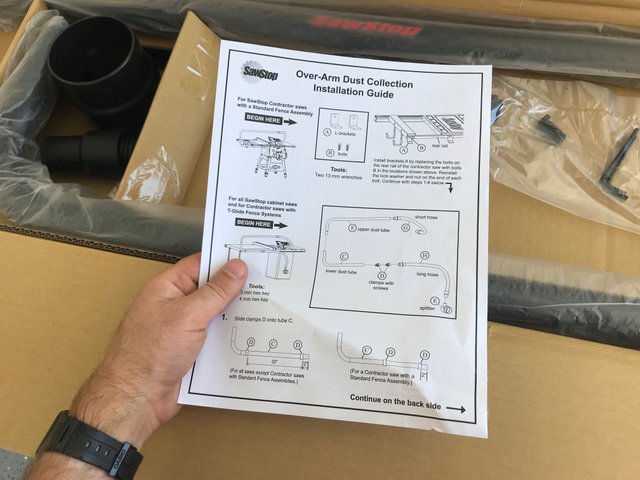

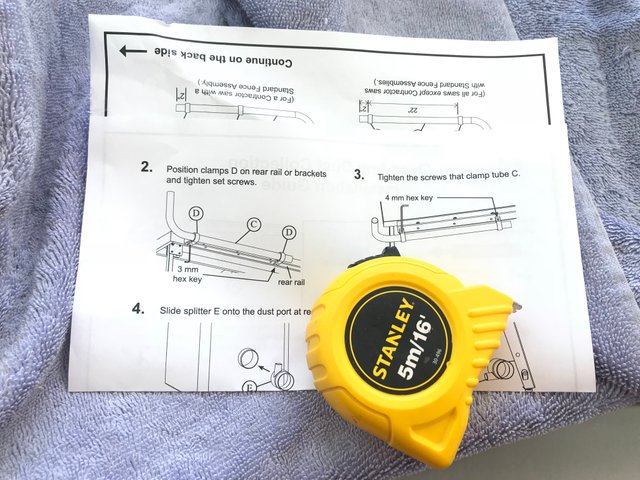

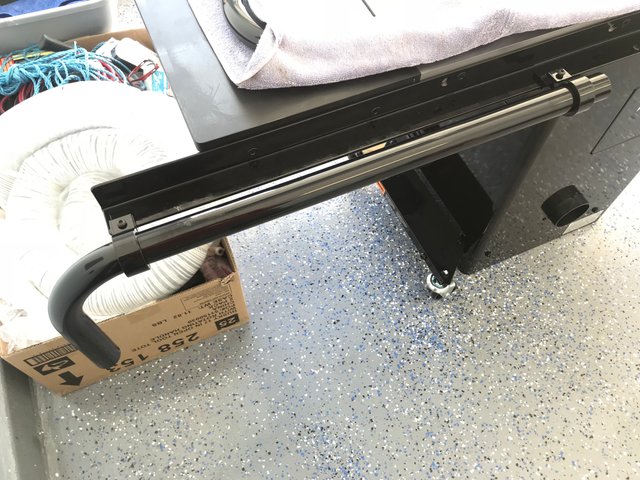

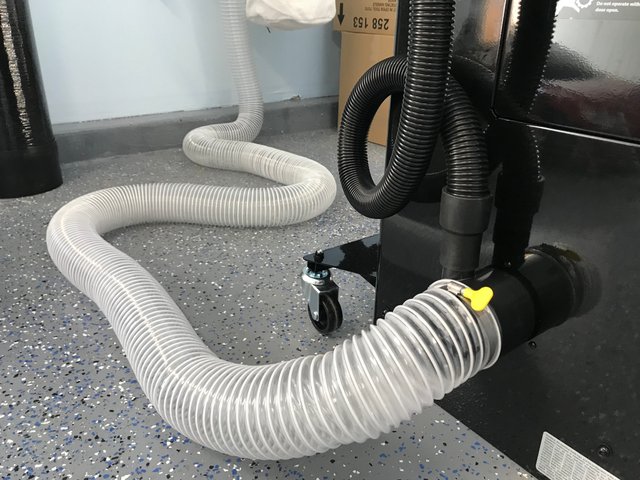

Dust Arm

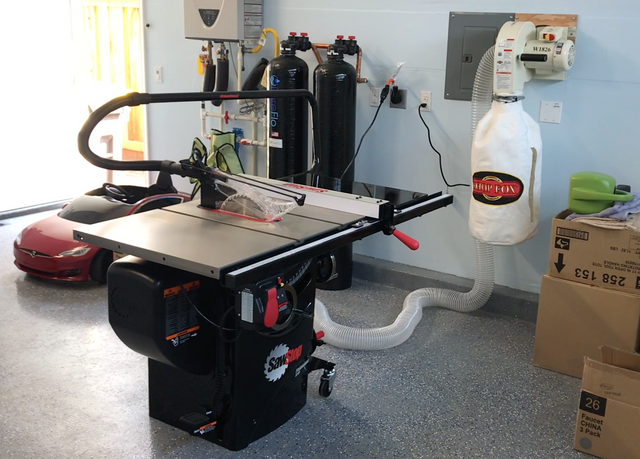

There is a dust port at the bottom and also at the back of the blade guard. This accessory is not essential but it felt like the right thing to do. I really want to minimise dust and make collection efficient. This joins the two ports while allowing material to pass over the saw bed unobstructed.By the way, I found out what accessories to put in the accessory holder! Riving knife, splitter/blade guard, and the mitre gauge for cross-cutting and some angle cutting.

During the meanwhilst, our water filtration system arrived. It is coconut-based because we can't use salt systems in this area. It is big but I hope to enclose it and build in a radial arm saw set-up. That's for much later.

Dust Collector

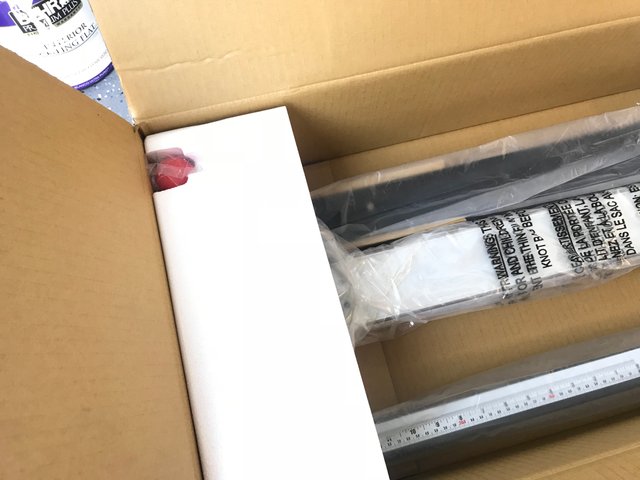

The internet said that this model comes poorly packaged in flimsy polystyrene. Let us see...

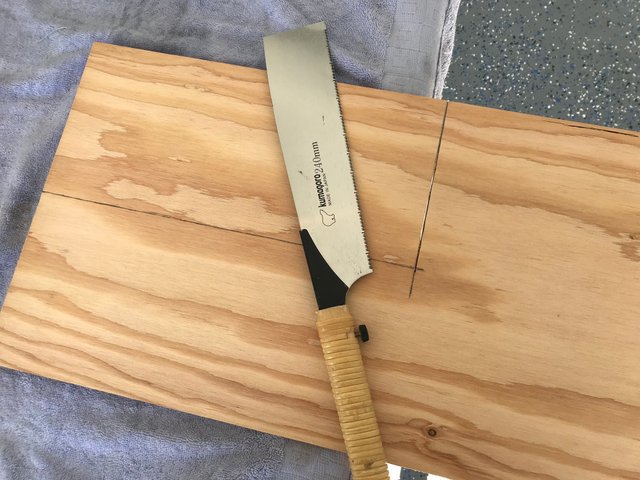

This may be a bit long, which could affect suction power. I can always cut it down.

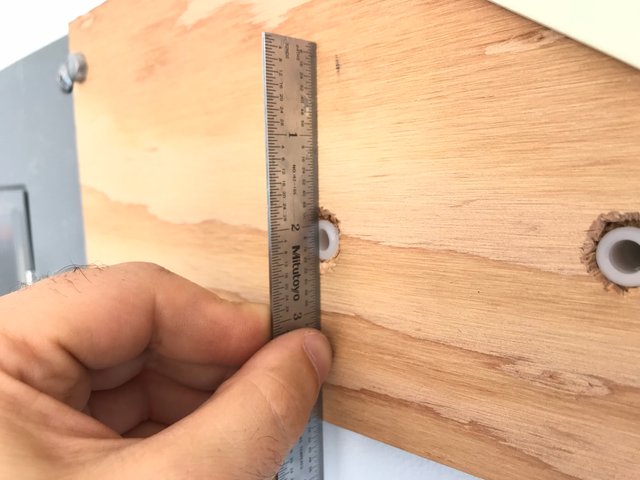

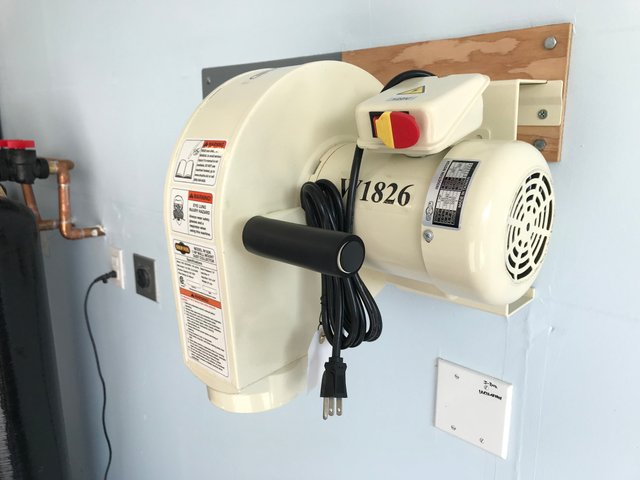

I need this to bridge two wall studs. This will make a secure foundation for the rather heavy appliance.

I was worried about screwing it in here because of possible mains power cables.

Stupidly, I just went for it, hoping that the electrical code requires vertical cabling only...

All of the house's power remained on, and I did not die at this time.

And throw in some wall plugs for good measure.

Make sure they're behind the surface.

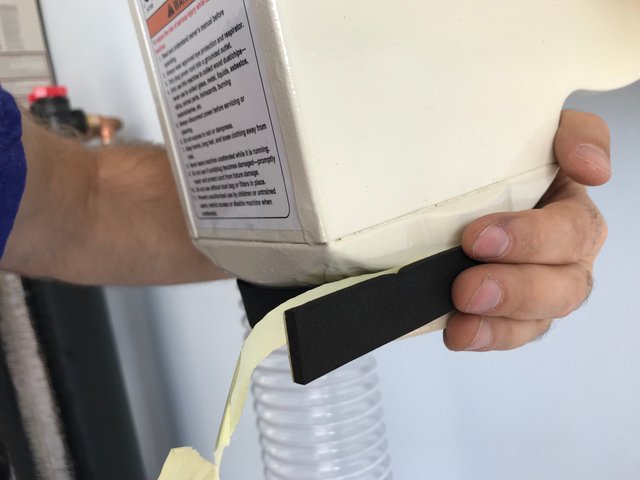

I was genuinely about to turn it on, before realising I had not attached the collection bag. Idiot.

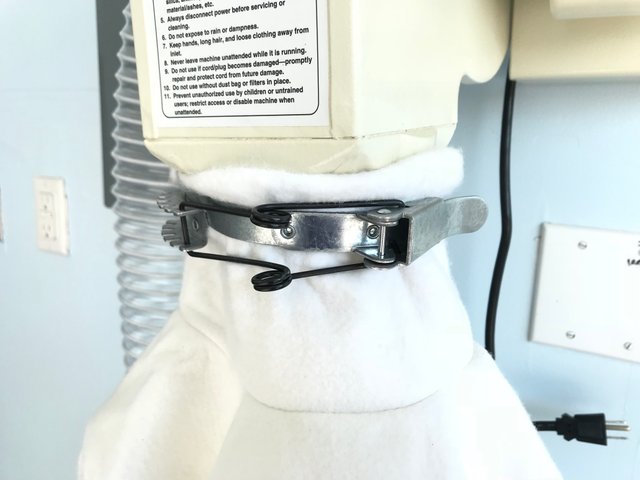

This clip was barely long enough. Quite tough to attach. Annoying...

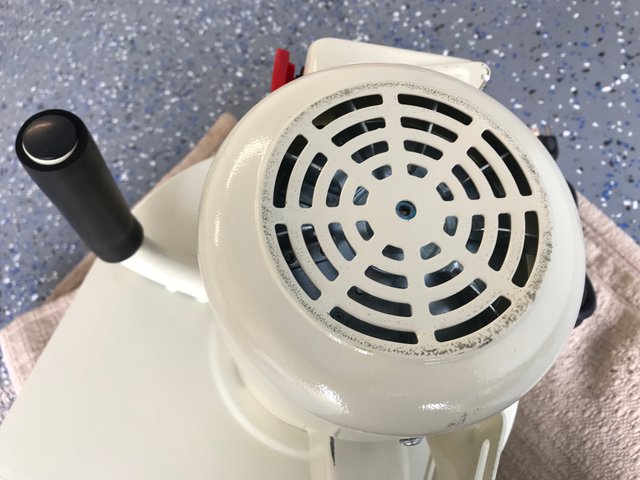

Then I turned it on. Instead of a lovely low hum, there was a scream of screeching metal. Terrified, I smacked off the power.

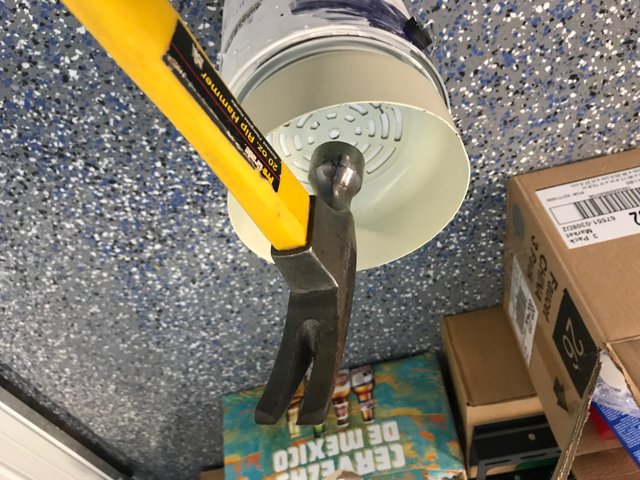

That packaging from earlier may have been the culprit. The fan cover was dented against the fan! Horrible! The company is sending a replacement, but in the meantime I performed some percussive maintenance.

Finagling

Last things last.The SawStop® man told me to use a clamp to clamp the bed to the rail, then tighten the screws. This is pretty straight now. It will be fine.

I installed the basic blade that came with the machine because I wanted to make sure everything was fine and did not want to ruin the good blade.

A man told me I could turn this socket around the other way...

That was a long one. Well done for making it this far. You are special.

Next up... WORKBENCH!

PS. The saw and dust collection work and are quite noisy. I may insulate the garage door...

Thanks for reading! Thanks. I love you.

Of course, the work is done very much. I like how you build your garage. I myself am a builder. I would not have enough patience. Have a nice day.

Just a little at a time, my friend :D

Great and amazing woodwork @lenskonig!! Very clean and fine work. My best wishes is with you. 💚🤗💙💚

Thank you :D

Great work engineer man.

Thanks :D

Everything is coming in shape the workshop space is looking awesome now with all the tools :)

Thanks! Yes, I'm getting there. As soon as my workbench is finished I can properly start to make things. Otherwise I'd have to work on the floor. But the Japanese do that, so maybe I'm being lazy.

Congratulations @lenskonig! You received a personal award!

Click here to view your Board of Honor