In the beginning there was 5S

Ever since the dawn of time man seeks to make woman happy and keep cave in 5S condition. Bows nice and tidy, dirt floor swept and sanitary with a place in the tunnel to scratch each internal audit. The benefits are almost immediate and the system seems to have a way of energizing the other "tribes." But even with success that dates back to prehistoric times why is it that 5S seems to have become the "beginners" project?

Truth is, there is an art to 5S that often goes unnoticed. Maybe it's the assumption of spring cleaning, possibly the intense effort it sometimes takes or maybe it's just how simple the system is but behind all the smoke and mirrors 5S brings together a set of proven techniques that when combined dramatically transform anything they are applied to.

Sorting

Let's take for example sorting. Separate what is needed from what is not needed. right? Wrong! It's actually more like separate what is needed from what is not needed taking into consideration critical needs and establishing a priority system based on the items frequency of use all while gently guiding the oh so needed torn apart and rusting to pieces tool box into the garbage bin. If you weren't skilled before the project started you will certainly discover your strengths and learn to acknowledge your weaknesses in the sorting phase.

Set-in-Order

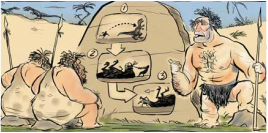

Now the junk is gone and there are a few piles of important items laying in groups according to how often they will be used. Fantastic! But alas it's only the beginning. Now we must set all items back in a designated space and then begin shining. Wrong again! Actually we would all love to think that setting things in order only requires a few core activities, but in hindsight setting things in order often times means laying out a "plate of spaghetti" and reviewing the flow of the shop floor. Then gathering labels and various sensory indicators to create a place for everything. After you have finished laying out a calculated flow for the newly sorted shop floor and gathering the necessary supplies now it's time to create the flow you laid out and clearly identify a place for everything ensuring that everything gets put in its place. Tools like shadow boards are assembled, wheels, axes and spears (see picture above) are placed in easy to reach positions and everything is placed in a carefully planned out order. The mere fact that teams coordinate these activities and make decisions based on consensus provides participants with an opportunity to become a team. One other very interesting fact related to setting items in order is that although it certainly will tidy an area up, the actual purpose of this activity is to remove any forms of waste (muda) from the area. This is one reason why we look to establish flow and place items in carefully marked boards or areas. The core principle with all the tape and shadow boards is not in fact to make the "cave" look pretty but rather to enhance the degree by which an abnormality can be identified. Here is an example, if I were to trace wrenches with a black sharpie I certainly would know where the item goes and upon further need for an item would be able to discover the abnormal condition if the tool was not their. Now if I were to cut a hole in foam in the shape of the wrench and line the bottom of that cut out with "cavewoman's" favorite color let's say bright pink, we may not even have to look to notice the tool missing. Aside from identifying abnormalities setting things in order reduce wait time (looking around), transportation (going and getting what you need), and many other forms of muda. While these experiences may sound familiar to those of you who have performed a 5S before, the system often get's set aside after our next step, shining.

Shinning

This ultimately is where our once sacred system turns into a mere method of cleaning (in some cases). In shinning the teams are challenged to clean with the intention of seeing their faces in everything. Or are they? Well yes they are, you're right on this one. But, there are a few other core reasons that often get overlooked in the scurry. The teams are tired worn down and emotions may come into play at this point in the game. The purpose of shining is actually much deeper rooted than just seeing your face in every item around the office or shop. The actual intention of shining is a few different things:

- Ensure the work area is safe and sanitary.

- Establish cleaning as a form of "inspection" and support of TPM.

- Jumpstart the initial mindset of daily maintenance and improvement.

Standardizing

After the shining is complete we then move on to in my own personal opinion the bread and butter of 5S, standardizing. This is often mistaken or confused with the activities that took place in the set-in-order portion of 5S. When we standardize activities we link sustainment with the first 3S's. Think of it like you are closing the loop. Whatever is done in this stage will determine the degree of sustainment you and your team obtain. However the policies and procedures must be systematic in nature. They must be checked maintained and kept alive in order for them to work. One very common practice is to assign a "5S manager." This is not a bad practice in the early stages of 5S development, but the goal should be to have "everyone" be "5S managers."

The policies and procedures established in this portion of the 5S should be shared with the entire team and any other parties that might be affected as a result of the 5S. Once the tribe agrees on these new "policies and procedures," the rubber will meet the road.

Sustain

Sustaining 5S is commonly noted as the hardest part of a 5S initiative. But really when you think about keeping a room in tip top condition it sounds easy. Maintaining 5S has more to do with what we do everyday that maintains the new condition. Because this often involves other people and culture or behavioral changes, 5S oftentimes fails to meet the condition we left the gemba in after shining. I recently experimented with a new concept at a local machine shop where we assigned accountability partners within the department structure. Using the same principles as any other accountability partners each person had a silent best friend who held one another accountable for their areas condition. The idea was to create an environment where every individual did their part ultimately resulting in everyone doing their part. The concept caught on rather quickly and turned out to be a big success. In order to avoid partners "keeping secrets" the teams still met each morning in huddle and reflected at the end of the day in hansei.

There can be no denying that a positive 5S experience often sends participants catapulting into a Lean mindset. The system provides benefits for the organization and upon completion excites team members. That momentum if used correctly often grabs many non-believers and turbo charges their lean conversion providing tangible results for everyone to see and feel. No matter what level of "lean" or skill set we are performing 5S can really hone, remind or strengthen individuals. If you train 100% of your employees in the 5S system and require each one to perform an initiative of their own, guaranteed you will see a return on the investment. In closing let's not discount the 5S system its benefits are quite powerful and often the results compound with each go around of 5S.

awesome

Thanks Joeyarnoldvn, have you heard of the 5S System?