IOTA DAG Tangle

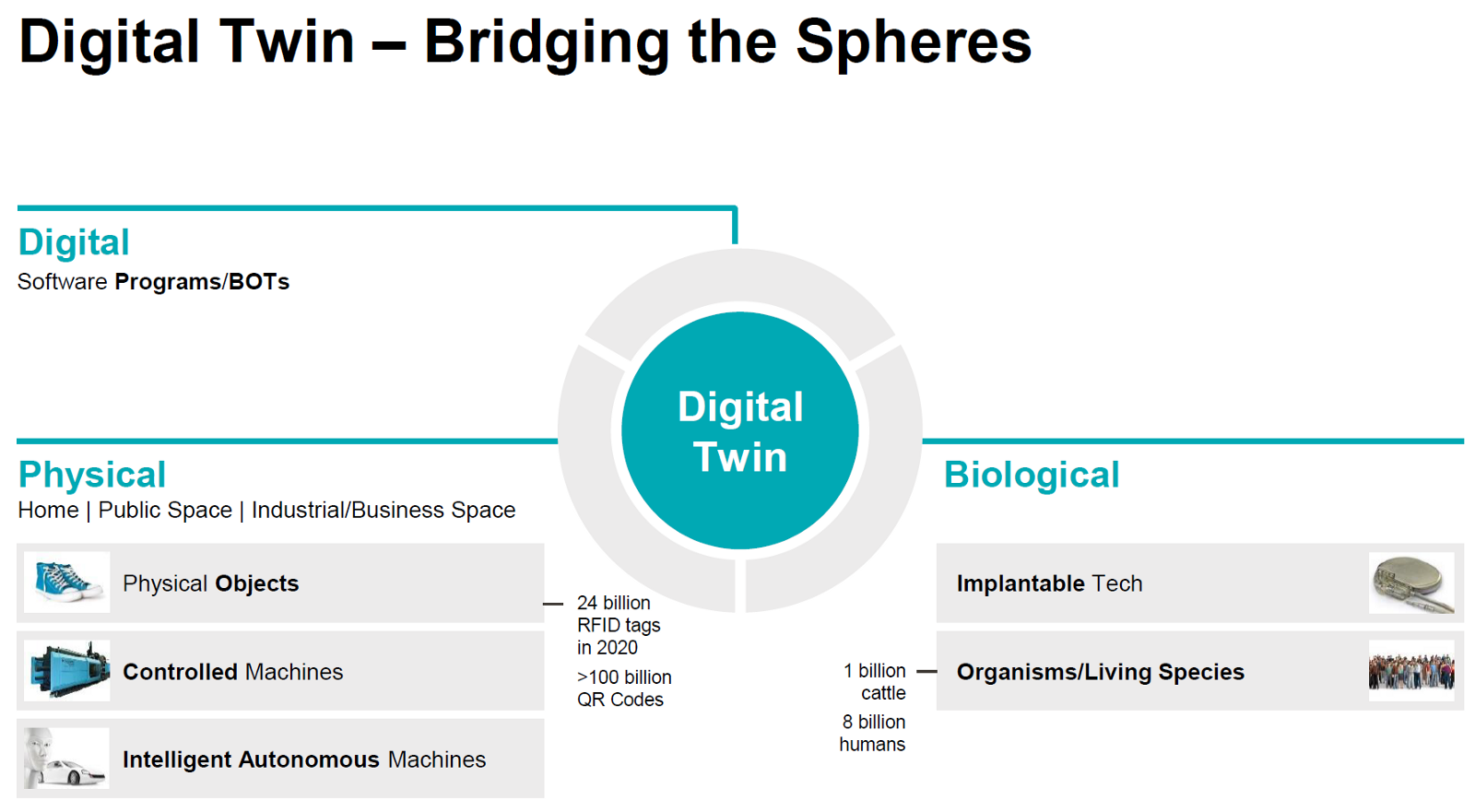

Implementing first Industry 4.0 Use Cases with IOTA DAG Tangle — Machine Tagging for Digital Twins Industry 4.0 is powered by the fusion of technologies that are connecting the dots between the physical, digital and biological spheres.

A variety of disruptive industry 4.0 technologies are now at their tipping point of being widely adopted in the next years. These technologies include — among others — electric cars, intelligent autonomous machines, decentral energy infrastructure, 3D printers, blockchain and AI/ML.

The combination of machines with blockchain and especially the IOTA protocol transforms these machines into economically independent devices that can transact among each other and form the basis of a Machine Economy in the 4th Industrial Revolution.

In this blogpost my preferred industry 4.0 use case will be described as a first example where the IOTA protocol can be applied in practice today: IOTA for tagging of physical machines in a digital twin architecture (proof-of-concept). This use case combines some very important decentral technologies such as IPFS, IPLD and BigchainDB for file storage and database layer with the DAG (directed acyclic graph) tangle as well.

We decided with this use case to start using IOTA in our project as it is practicable to implement and clearly demonstrates selected very compelling features of the DAG tangle.

I will describe how we are exploring IOTA in a second industry 4.0 blogpost about Share & Charge EV car charging (conceptual).

Digital Twin: Every Product has its own Story

One of our main Industry 4.0 innovation projects is the digital twin (or digital product memory). A digital twin is a digital representation of a physical, biological or digital object. Our innogy Digital Twin project “Twin of Things” seeks to give every physical object a story. innogy is now forming an open IoT and supply chain ecosystem to bring this vision into reality.

Connecting the digital, physical and biological spheres with the digital twin concept

A digital twin can be created with manufacturing, production and design parameters even before a physical object is even existing telling a manufacturing unit how a physical object needs to be produced. It can store data how the object was assembled, tested, transported, deployed, operated or decommissioned.

The digital twin is a key concept for bringing industry 4.0 to life supporting a broad variety of industry domains including Energy, Mobility, Supply Chain, Consumer Goods or Health Care. It provides many technical benefits for different use cases and solves many of today’s problems while fulfilling industry requirements such as batch size 1 manufacturing, back-to-birth-traceability, provenance, authenticity, tracking, optimization, auditing and compliance.

High-level Digital Twin Value Proposition

In addition a digital twin enables further innovation by establishing a digital experience among objects and their owners and or by opening up new forms of marketing.

Marketing can move from person focused marketing to object marketing. A manufacturer or retail organization selling a handbag for example is trying to get hold of the personal data of a customer at the point of sales. A user is typically offered a loyalty programme to provide the data in return. The manufacturer or the retail store have all what they need to exploit these personal data for their own purposes.

Digital Twins in Marketing

A physical object with a digital twin will change old fashioned loyality programme marketing dramatically. A manufacturer or retail store do not need the personal data any more. They only need to know the object identity which enables a marketing function to send marketing and sales messages directly into the digital twin. A customer with its registered objects in an App will get an alert whenever a message from a marketing functions arrives in one of its digital twins. And of course a customer can decide to disable the alert or take write access away for the third parties.

The object marketing is a very powerful new marketing tool for the customer shifting the balance from corporate marketing functions to customers. In addition, object owner can connect anonymously among each other to share their product experience by sending messages among each digital twins. And of course a customer can disable this community feature as well.

In addition a digital twin can store, manipulate and transfer tokens. This includes access tokens, token of value, loyalty tokens or proof of something tokens (e.g. product age smaller 5 years, compliance token, authenticity token).

There are a lot more unexplored innovative features within this technology.

Technical Implementation

As objects are interacting with other entities over their life cycle, ease of interaction with the digital twin and control over object data are key features that can be fulfilled with decentral, blockchain-like solutions. The other key feature is the cryptographically secure tagging of objects.

To implement a decentral digital twin solution the respective object data need to be stored in a decentral database, connected with analytics and gathered from a physical object or machine.

This leads to the following high-level technical requirements:

Ad 1. Data Storage

Interoperability along the life cycle

Immutability of the data for compliance, trust and auditing

GDPR compliant data access management and transfer of assets empowering the object owner’s control over the data and the object

Data indexing and queries for analytics

We are using BigchainDB as decentral database for storing data in an immutable way and to enable analytics on top of a database. We use BigchainDB Access tokens to for access management giving full control about the data to the owner of the object. A variety of Automakers are starting to explore the potential of a blockchainified database layer.

Ad 2. Data Gathering

Tagging of objects to provide a cryptographically secure identity

Data authenticity of data gathered from an object linked to its IOTA identity

Data integrity of data gathered from an object ensuring that a third party has not tampered with the data in the communication layer

Data encryption

We are testing IOTA for tagging machines and providing a secure and trusted data transaction layer for extracting data out of the machines into the digital twin.

IOTA on the Device

We start using IOTA to tag physical machines giving machines an identity on the DAG tangle. These identities are then stored in the DAG tangle and in a device registry which, is in our case, on BigchainDB.

Digital Twin Architecture

In addition to the IOTA device identity further metadata or attributes are stored in the registry describing the device and making it searchable in the indexed database.

The IOTA integration with IoT devices provides integrity and authenticity of data gathered from sensors or sent to actuators of a device.

To address vulnerabilities inside a machine — e.g. via message injection through a malicious third party — the sensors or actuators receive their own cryptographic identity using methods such as crypto chips or IOTA light nodes on sensor / actuator level. The identities of sensors / actuators are registered in the DAG tangle.

All these devices communicate inside a machine with an IOTA gateway note that acts as or it is integrated with a telematics gateway connecting sensors and actuators with systems in the outside world, especially our digital twin platform. A more complex machine can have its own IOTA DAG tangle sub-branch or even clusters of sub-branches validating transactions and dataflow inside the machine.

CarPass: Vehicle Telematics Data in a Digital Twin

A practicable first application of a digital twin with IOTA is CarPass for vehicles telematics data. The CarPass solution securely captures telematics data (e.g. mileage, trips, environmental, maintenance data) and stores them immutable in the digital twin for private passenger, fleet or commercial vehicles.

Working CarPass Implementation

This special digital twin enables a vehicle to tell its story where it went, what it did and how it was treated. The car´s history along its lifecycle is captured in the digital twin. This provides many benefits for fleet managers, work shops, processes involving multiple parties, logistics companies or cold chain operators.

As the most simple and straightforward benefit this solution provides an auditable and tamper-proof mileage history, preventing odometer fraud in the second hand car market.

How was the car driven? Few trips long distance or many trips short distance? How was it maintained? The answer to these questions pretty much determines the value of the car. CarPass can answer these questions in a trusted way.

innogy is now piloting IOTA for ensuring this trust in telematics data coming out of a vehicle. We are connecting the IOTA node with a telematics device. A further step might be to integrate IOTA in a telematics device itself. Further integration with sensors and actuators in a vehicle will be evaluated in order to extend the trust into the vhicle infrastructure down to the sensor level.

This end-to-end architecture is especially important to eliminate vulnerabilities for tampering via e.g. malicious message injection inside a car.

IOTA is a young technology with a not yet fully proven cryptographic foundation, but with a promising potential that deserves adoption for initial use case testing and prototyping.

Of course there are real world and cyber security risks in adopting such a technology. We are aware of the risks and the development roadmap of missing features going forward. We believe that building prototypes is a reasonable way to better understand the technology and its underlying risks.

In partnership with other enterprises and key teams including the IOTA foundation, innogy gets new ideas to live, in order to demonstrate through concrete examples the capabilities and potentials of blockchain technologies as it relates to physical assets, objects, machines and devices.

relink: https://medium.com/@cstoecker/implementing-first-industry-4-0-use-cases-with-iota-dag-tangle-machine-tagging-for-digital-twins-baf1943c499d

(no rewards)

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://medium.com/@cstoecker/implementing-first-industry-4-0-use-cases-with-iota-dag-tangle-machine-tagging-for-digital-twins-baf1943c499d

@shapoy thank you

@shapoy I happy you come to my place. thank you.