Local Cassava Processing: The Making of Garri

Local Method of Processing Garri.

Local Method of Processing Garri.

Processing Garri

Garri and soup is a staple food among the Ibibio people and the Efik People of Crossriver State in Nigeria. Garri is a product of cassava, and it contains a lot of carbohydrates. I will be showing you how I make garri at home.

It starts when we harvest cassava, the root crop known as Manihot esculenta. At this point, it is raw and will pass through some processes to make it edible.

Peeling:

The process switches to the removal of the cassava's peel. It takes a considerable amount of time, depending on the amount harvested and the moisture content of the cassava. The peeled cassava is washed and immediately taken to the grinder for grinding.

Peeling the cassava.

Peeling the cassava.

Crushed and Squeezed:

At the grinder, the peeled cassava roots are fed into a machine that grinds the cassava into a smooth mushy pulp.

The pulp is then put in a bag and moved to a press that squeezes out water from the pulp. This would take a day, during which the pulped nature of the cassava will quicken its fermentation process, breaking the harmful toxins into useful nutrients.

Man operating a cassava press.

Man operating a cassava press.

When that which came in as a pulp is out of the press, it has been squeezed dry into a crumbly residue, a dry cake ready for the next process.

Cassava cake out of the press.

Cassava cake out of the press.

Grading with a big mesh:

The crumbly moist dry cake is placed on a sieve. The sifting process removes some excess fibre, giving the end product a homogeneous look made up of fine grains, adding air to it and getting it ready for the final drying process.

My kids, Learning while helping me with sifting.

My kids, Learning while helping me with sifting.

We use the filtrate and dispose of the residue. The fine filtrate is ready for the next process.

Pan-drying, Roasting and Toasting:

The filtrate is put in a preheated pan, I add some palm oil to give the finished product an attractive colour and improve its nutritional value. To get a beautiful aroma, when the garri is dried, you simply toast it a little more.

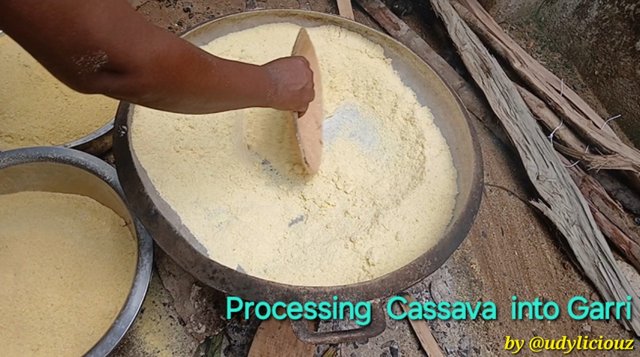

Garri in the hot pan, drying out.

Garri in the hot pan, drying out.

Drying is carried out on a firewood powered fireplace, adding some smoky flavour to the Garri. The main work here is the continuous steering. This avoids the development of lumps in the garri.

braking down lumps during drying.

braking down lumps during drying.

Taking advantage of the hot ash to create a local snack with toasted palm fruits. Cooked by the hot ash, the palm fruit with its ash coating is a local delicacy.

|  |  |

|---|

Conclusion

The Garri is ready, safe for consumption with plenty of carbohydrate. It can be preserved for months.

Some get bagged and sold in local shops.