"Industrial Automation(PLC) and Electrical Motor Faults."

I am @shadow04 Hope you all are well by the grace of Almighty Allah. Alhamdulillah, I am also very well. Today I appeared to participate in the ongoing SLC22/WK4: Industrial Automation(PLC) and Electrical Motor Faults. At the beginning of the competition, I would like to thank @mahadisalim sir for giving us such a beautiful lesson.

From #bangladesh🇧🇩

"Industrial automation" refers to the use of automated machines instead of humans in the industry to make work more accurate, faster, and cost-effective.

Since the machine does not need to rest like a human, it can continue to work continuously (in special cases, with temporary breaks to prevent the machine from breaking down), so it can perform a task faster than a human. Again, input a specific measurement to the machine. Given that it does not make the slightest mistake, but is easily made by humans, so machines can perform tasks more accurately than humans. Basically, Industrial automation works with the help of sensors, robotic systems, control systems and other essentials. runs

The importance of industrial automation during the industrial revolution is quite noticeable. Industrial automation was especially important in the third and fourth industrial revolutions.

Although the influence and spread of industrial automation was not present in the 1st and 2nd industrial markets, the basis of industrial automation was formed at that time. As an example, we can refer to the phenomenon of electric power during the 2nd industrial revolution The use of electricity increased the efficiency of machines and increased the use of automatic machines, which contributed greatly to the industrial revolution.

During the third industrial revolution, industrial automation was widely spread, the reflection of which can be seen very well. Because at this time, using programmable logic controller or PLC and robotic technologies, "robotic arm" and CNC machines were invented in various large factories, which made industrial production faster and more accurate.

The role of industrial automation in the fourth industrial revolution is truly unparalleled. Here technology has proved how much happiness it can bring to human life. In this industrial market, with the help of industrial automation, machines themselves analyze various things and continue to work. Which has taken our world several thousand steps forward.

|

|---|

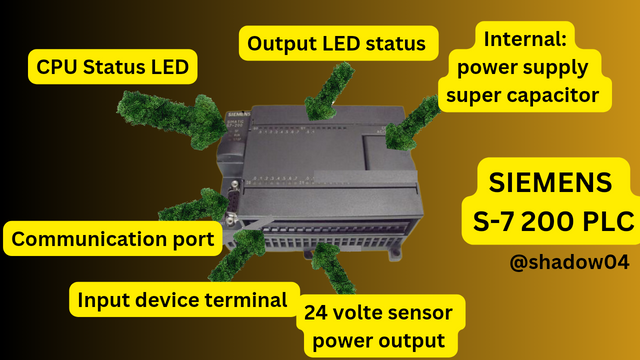

Various names of a PLC and their functions are mentioned below:-

- Through the CPU status led, the operation and error of the PLC can be identified. For example :- PWR light on means that PLC is active. Green light indicates active status. Yellow light indicates PLC stop and red light indicates any internal PLC error.

• It refers to the output channel status of the PLC. For example, ON means the output is active, OFF means the output is inactive and Blanking means the PLC is repeatedly switched on or off or an emergency condition.

• It is used to store the temporary data of PLC when the main power supply is off. And because of the system of auto charging, it is automatically recharged when the main power supply is present, and later, when the main power supply is off, it can provide about 100 hours of data backup.

• This Sensor power out.24V power provides enough power for the sensors of the PLC to provide the amount of power required by the sensors to effectively generate the signal and send it to the PLC.

• Input device terminal collects the signal from the input device and supplies it to the program. It usually works as Digital input or Analog input to receive these signals.

• Communication port is used to ensure data exchange between PLC and other devices. So it is an important part for PLC. How far data can be exchanged depends on the type of communication port.

In the electrical sector there are countless input and output electrical and electronic devices that are operated by PLC. Five of these devices are mentioned below:-

- Push button switch:-It usually sends a signal to turn on or off a machine.

- Limit switch:- These convert the mechanical movement into digital signal and decide how long a device will run.

- Proximity sensor:- Capable of detecting the presence of an object at a certain distance from a metal or non-metal device.

- Photoelectric sensor:- Detects objects using light.

- Temperature sensor:- measures the temperature of an object and sends it to analog.

- Solenoid valve:- ON/OFF signal is transmitted digitally.

- Relay:- Used to ensure electrical isolation between different devices.

• Motor starter:- Used to start or stop large electrical motors.

• Indicator light:- Used on control panel to display machine status.

• Buzzer:- Used to give warning signal.

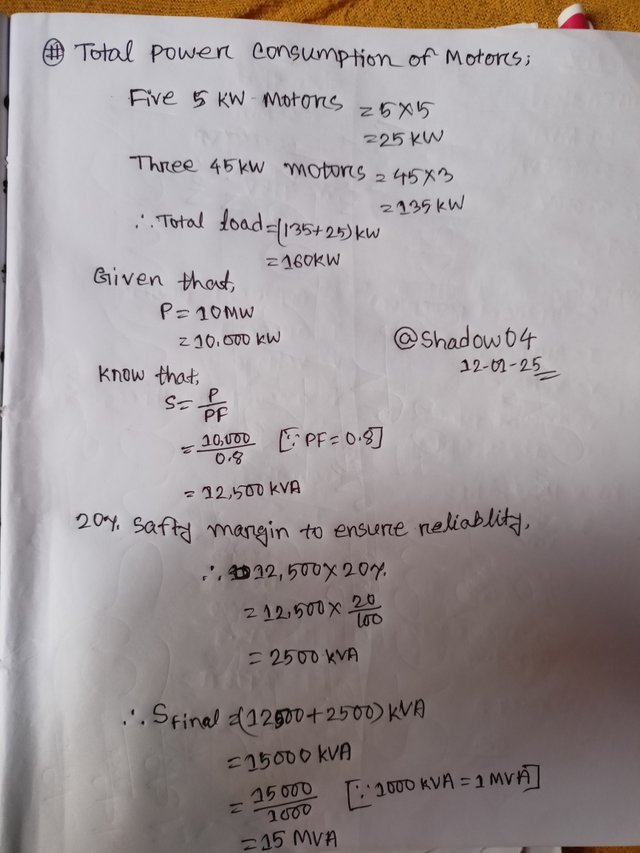

- Transformer Specification:-

| Rating | 15MVA |

|---|---|

| Type | 3 phase |

| Frequency | 50 Hz |

| Power Factor | 0.8 |

| Primary voltage | 11kV |

| Secondary voltage | 415 V |

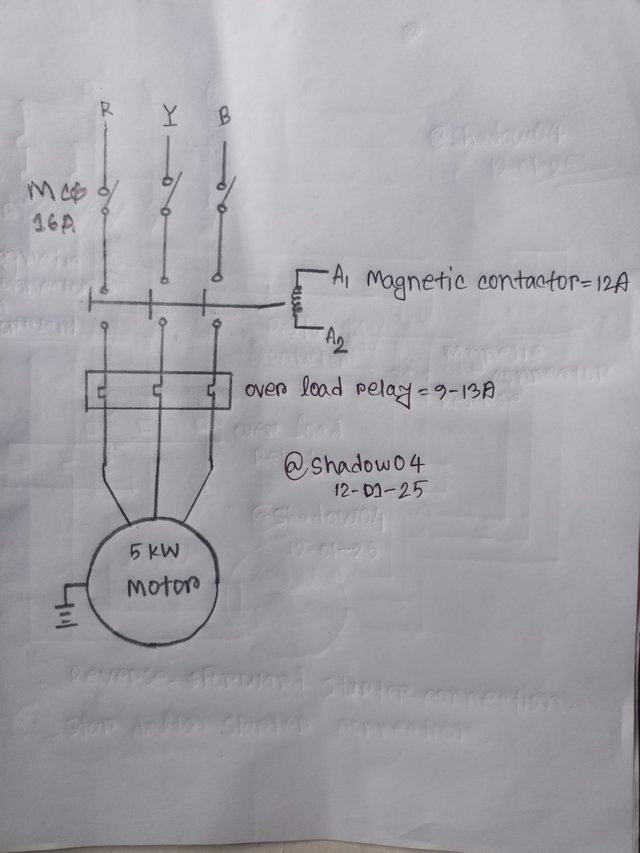

Using a delta starter on a 5kW motor can reduce the inrush current, which can cause the motor voltage drop and reduce motor damage. It can also ensure the performance of the motor.

- The starter (power circuit) drawings and required materials for running a 5 kW three-phase motor are mentioned below:-

| S.L | Required materials |

|---|---|

| 1 | Switch. |

| 2 | Three phase motor |

| 3 | Three phase supply. |

| 4 | Overload relay. |

| 5 | Emergency stop button. |

| 6 | Fuse. |

| 7 | Stutter. |

| 8 | Three Phase Circuit Breaker. |

| 9 | Three Phase Contactor. |

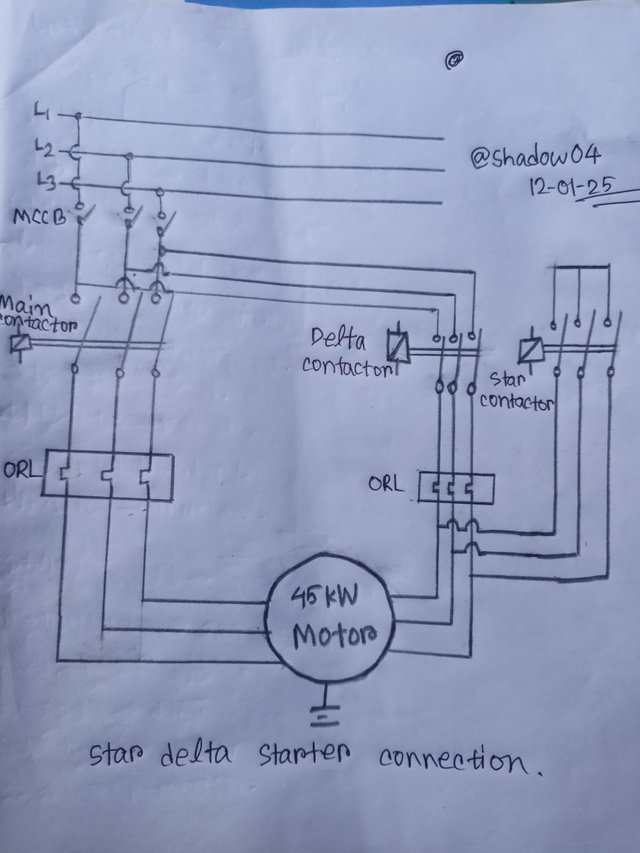

When the 45kW three phase motor reaches full speed, the delta configuration changes so that the motor can work at full power. It helps the motor to accelerate slowly by applying less torque while starting the motor. Also ensures the protection of the motor.

• The starter (power circuit) drawings and required materials to run the 45 kW three-phase motor are mentioned below.

| S.L | Required materials |

|---|---|

| 1 | Switch. |

| 2 | Three phase motor |

| 3 | Three phase supply. |

| 4 | Stutter |

| 5 | Fuse. |

| 6 | Three phase syfuse. |

| 7 | Indicator light. |

| 8 | Three Phase Circuit Breaker |

| 9 | Three Phase Contactor |

| 10 | Overload relay. |

| 11 | Emergency stop button. |

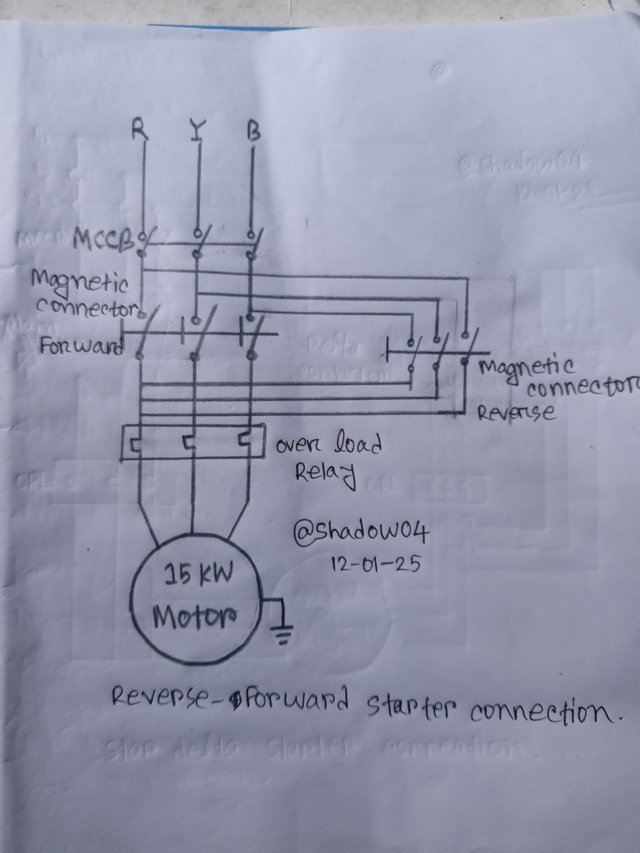

Forward and reverse starters are used for 15kW motors as they allow the motor to be rotated in either direction as required. Motor direction control is easy, reducing the risk of overload and short circuit, helping to ensure safety and efficiency when starting and stopping large motors.

• An inverted motor circuit has to be made to place the 15 kW motor in the specified place and to run in both directions.

| S.L | Required materials |

|---|---|

| 1 | Switch. |

| 2 | Three phase motor. |

| 3 | Three phase supply. |

| 4 | Three Phase Contactor |

| 5 | Three Phase Circuit Breaker. |

| 6 | Three phase syfuse. |

| 7 | Indicator light. |

| 8 | Overload relay. |

| 9 | Emergency stop button. |

| 10 | Wiring. |

| 11 | Fuse. |

| 12 | Stutter. |

- The motor test result looks good to me. My opinion about this result is mentioned below:-

Star-Delta Connection:- As the motor power is more than 5 kW. So it is important to use star-delta starter here. It will help the motor to run smoothly for a long time.

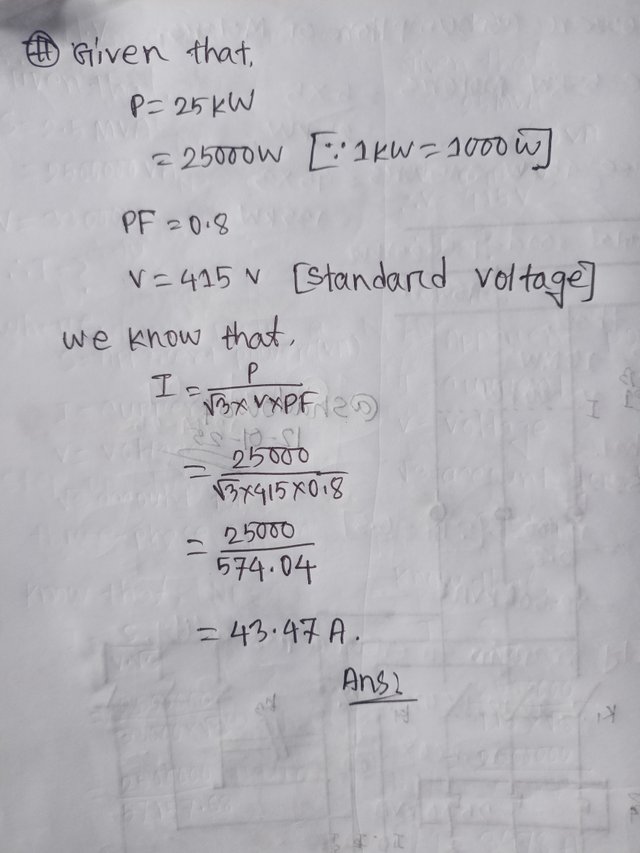

Also, using the values you mentioned, I have calculated that your motor's power is correct.

Your motor current is 43.47 amperes but as magnetic conductor I have used a conductor of 85 amperes ie almost double rating. Which is enough to avoid accidents. Also MCCB, Overload relay and timer are all taken right by you.

- Thanks by,,

- @shadow04

|

|---|

X promotion link :

https://x.com/MdNasirHos74975/status/1878502406063096057?t=2a3ZjPFIiicxPw8sLrll2Q&s=19