Source:CANVAS Hello friends, how are you all, hope all is well, today I am going to write an educational post related to my stream in front of you guys. Which is related to my subject. I am a mechanical engineering student and I discussed the subjects with topics which I read studies in my student life. Without taking much time, today I start my Subject.

Hello friends, how are you all, hope all is well, today I am going to write an educational post related to my stream in front of you guys. Which is related to my subject. I am a mechanical engineering student and I discussed the subjects with topics which I read studies in my student life. Without taking much time, today I start my Subject.

MANUFACTURING PROCESS

| Manufacturing process can be classified on the basis of |

|---|

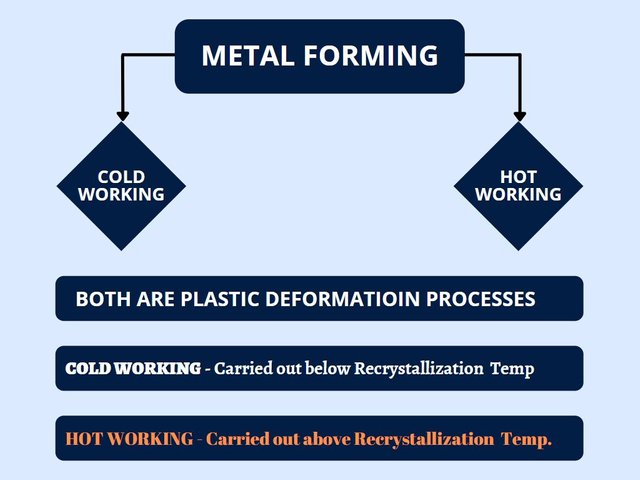

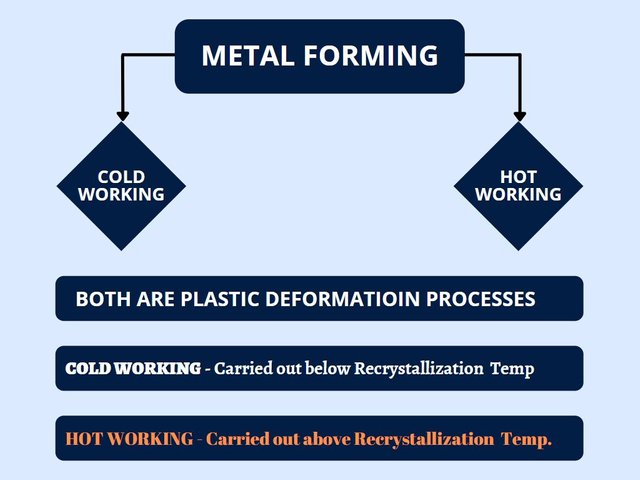

- Metal forming

- Metal Removing

- Metal joining

In Metal forming we can learn following topics |

|---|

| Metal forming | Metal removing | Metal joining |

|---|

| rolling | turning | Riveting |

| spinning | milling | soldering |

| extrusion | Grinding | Brazing |

| drawing rods wires tubes | Shaping, planing | Welding |

| forging | broaching | - |

| presswork | - | - |

| casting | - | - |

| ADVANTAGE OF MECHANICAL WORKING PROCEESS |

|---|

- higher productivity suitable for mass production

- high standard quality of fabricated products

- higher strength better corrosion and wear resistance

- minimum waste of metal

- higher dimensional accuracy and surface finish

- strength can be increased

- As grain of materials get elongated in the direction of metal flow better mechanical strength can be achieved.

- Extra thin foil wire steel sheet etc can be found by mechanical working only.

| ADVANTAGES OF COLD WORKING |

|---|

Source:

No oxidation and scaling material loss reduced.

- surface defects removed

- excellent surface finish

- higher dimensional accuracy

- good for mass production and automation

- material become work hardened, therefore strength increases

- physical property of metals which do not respond to heat treatment can be improved.

| DISADVANTAGES OF COLD WORKING |

|---|

- Large forces are required for deformation.

- ductility or formability of metal is low at low temperatures, inter stage annealing is required, increases the cost of production

- difficult to produce complex shapes

- sensitive controls are required

- only ductile metal can be cold worked.

material commonly used for cold working

- Low medium carbon steels (0.25 to 0.45%)

- low alloy steels

- copper and its alloys

- Aluminium, magnesium, titanium, beryllium etc.

| ADVANTAGES OF HOT WORKING |

|---|

Source:Pixabay

- The strength of metals is low at high temperature hence low tonnage equipment are sufficient.

- Very large workpieces can be deformed.

- Because of high ductility at high temperatures and absence of work hardening, large deformation can be undertaken.

- Interstage annealing & stress relieving are not to much required.

- Blowholes and porosities are eliminated.

- Grain size can be controlled to be minimum. Metal become tougher.

- Segregation may be reduced or eliminated, since hot working promoted diffusion of constituents.

TYPICAL HOT WORKING TEMPERATURES

| Metals | Temperature limit |

|---|

| Steel | 1100 - 1260 |

| Cu and its alloys | 760 - 925 |

| Magnesium | 315 |

| Aluminium and its Alloys | 370 - 455 |

| DIADVANTAGES OF HOT- WORKING |

|---|

- Due to oxidation and scaling, heavy material loss. Results in poor dimensional accuracy and surface finish are also not so good.

- Automation is difficult due to high working temperatures.

- Thin parts (sheets, wires etc.) Cannot be produced due to loss of ductility at high temperature.

- High energy cost to heat the metals to high temperature.

- Surface decarbonization in steels reduce strength and hardness on the surface.

- Due to high working temperatures, surface reactions between the metal and the furnace atmosphere occurs. Reactive metal like Ti, required inert atmosphere.

I hope you all of my steemit friend liked this tutorial. So please tell me in the comments, what you liked in this tutorial.

Thankyou and have a great day ahead!

Thank you for contributing to #LearnWithSteem theme. This post has been upvoted by @cryptogecko using @steemcurator09 account. We encourage you to keep publishing quality and original content in the Steemit ecosystem to earn support for your content.

Regards,

Team #Sevengers

Hello friend, I wanted to ask you if you would be interested in forming a curation team with me.

I'm @rafaelcmontero, Venezuelan, Steem Travelers Mod. #club5050

my discord

rafaelcmontero#6630

telegram group

https://t.me/+R3Gh8zOR0iJhYjcx

Thanks for inviting me brother but I already with my previous team.

Hello my dear friend @deepak94 . I just start again my new journey in this platform. I stopped writting my post because our previous community close now. I can see that you are doing a great job in this platform. Your post is much more knowledgeble for technical students.

Thanks for stopping on my post @varsha001.

You explained all the terms in a short way thanks for sharing your tutorial post.

thank you shubham bhai.

You explain very well this tutorial is helpful for those who are preparing for competetive examination

Thank bro for your appreciation.