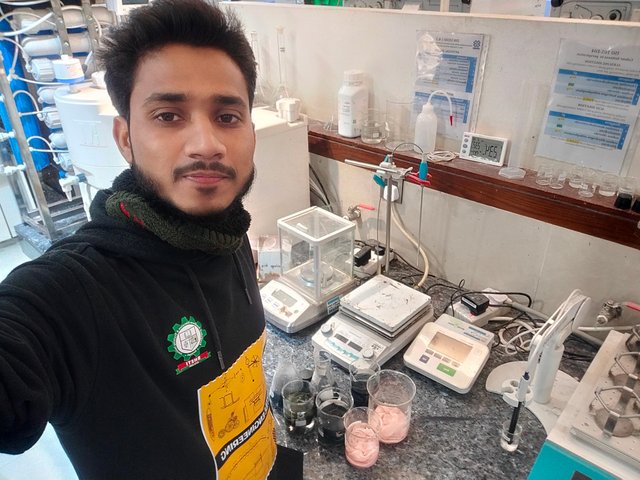

| Weekly Reflections #31: Lessons from my Profession! || A Textile Engineer and his Testing profession.

Hi, This is @mdyousufali, From Bangladesh🇧🇩

Hello Steem Flowers.

hope you doing well, this is mdushey poly from Bangladesh. my profession is a textile engineer. I start with my work at Mustafa export Limited as a laboratory testing fabric Technologist. I work my duties the AATCC methods and ISO methods . this methods we used to find out different testing purpose in fabrics and garments. In fact, we use Double AA ATTC and ISO method to check various types of test performance mechanical physical or chemical test of fabrics and garments. This is a first step in my profession, we as engineers are assigned these tasks because of which we basically have to do these tasks. In fact, we have different types of tips from different countries according to different buy requirements according to different methods. The tests themselves are done according to different methods. If we do not assume that we are testing a European country, we must follow the discussion. If we have ever done a test performance for a country like Saudi Arabia on the continent of Asia. They are definitely not made by ATCC. So there are many differences between ISO method and ATTC method especially temperature time and RPM control parameters are different. So basically we test the method used in different country wise. The brothers tell them to follow the payar bathar of Bengali and follow that way. It is the first of my profession. step or a part of profession.

Here I will pH one of my fabrics in AATCC Method So in this case first we have to cut a fabric weighing 10 grams. If it is gray fabric then we have to cut it from any part but if it is garment. In that case each part ie some part from garment, some part from board, some part from banana, some part from cup or others from any party. We have to take some parts from each par and weigh ten grams so that the exact amount is 10 grams. Then we have to raise the piling temperature in 250ml of water i.e. 100 degree Celsius temperature so that it becomes in water now we will give this sample piece in that water. And after giving the sample again we will give it to the heater and with the heater we must have a temperature of 100 degrees Celsius. When the temperature finally rises to 100 degree celsius, do we have to keep it in bowling condition for about 10 minutes, i.e. let's say we have to hit 10 minutes before that temperature.

Then when 10 minutes will be at volant temperature then it should be kept down to cooling temperature. It should be cooled in such a way that it may take two and a half hours or three hours to bring the temperature down to zero degrees Celsius. Then when it gets fairly cold, then it is electric, we will measure the PS of this water with the electrode of the pH meter. We must be careful in measuring water piece so we need to take 20 to 30 mL of water where 10 cm of electrode is immersed in it. Then we have to extract Everest from the next rating by taking two ratings in this way. This Everest will be ours tomorrow please and then we make a recording. In fact we as a textile engineer have done all the testing related to textiles. But as a testing engineer physical tests of bricks or garments mechanical tests or chemical tests are there. It is our responsibility to inset them and quality government is also our responsibility.

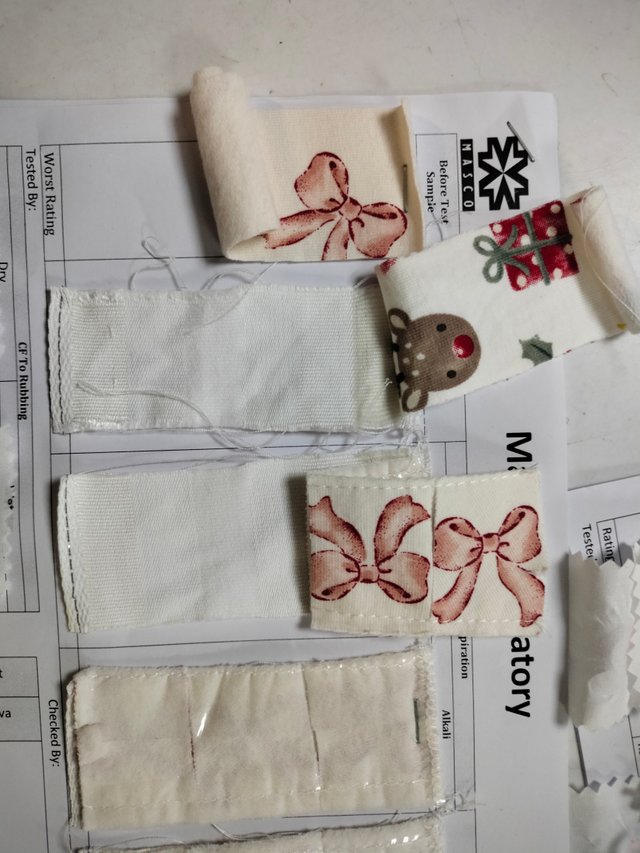

Here are the various assessment procedures for IS and 105 C06. So to do the assessment of this test we must go to a light box that light box will need like d65. So we have to go to this light and message while messaging we must use gray key. From the drill we will definitely take care of color changing color staining and contrast. A fabric can have different parameters and can be printed with different colors. In that printing, we must pay attention to the colors, color loss, color change, staining. So if the color of the printing goes up from there, that is, it was dark color before, but now it is light color. Then we call it color changing. But if those dark colors get out of the printing and stick to the background of the fabric, then what do we call it color staining? And if there are multiple colors in the same printing, if one color sticks to another color, then it is called cross staining. So these things we must keep in mind while associating. In your testing profession, of course, we have to look at or notice these things very important, so maybe it is possible to store quality. So this was a profession of a testing textile testing engineer so everyone will be fine and healthy.

@karianaporras

@kouba01

@ripon360

Best Regards

@mdyousufali

THANKS ALL

THANKS ALL

Well, it looks like an interesting job friend. Your post gives a detailed explanation of the role of a textile testing engineer, explaining the importance of different testing methods like AATCC and ISO. Thanks for the valuable knowledge and entry!