Industrial Automation(PLC) and Electrical Motor Faults.

As scholars continue to undertake innovative researches, the world system will continue to experience a shift in operation. The engineering field is not left out as lot of innovations have been recorded with lots more to come. All these are to make life easy, I suppose.

Greetings to our tutor@mahadisalim for sharing this quantum of knowledge with us. I am grateful to be a part of this class as I'm getting to understand salient information from the class and to my fellow students, congratulations for making it this far; I don't know if you will agree with me that it hasn't been that easy but that gives it the spice.

Alright...lets get to the solution of the classwork

What do you understand by Industry automation?

Industrial automation

Industrial automation is an innovative way of carrying out a simple or complex process in an industrial setting with the aid of a computer system that has been programmed to carry out such task with an increase in its operation speed compared to the manual process carried out by man.

Write about the Importance of Industrial automation during the Industrial automation.

There are lots of pros compared to cones of industrial automation. It increases the production rate of goods in industries. There is high efficiency unlike the manual process involving humans who may get worn-out with time. It enhances safety especially when dangerous materials are involved. It is cost efficient. There is improvement in the productivity rate when automation is involved. It can as well help to combat labor shortages especially in industries where people are scared of working there due to the complex structure and the level of exposure to hazards. The employment of industrial automation is of an advantage when considering its reduction of errors, unlike humans who are prone to lot of errors when working on certain task.

Write the names and operation of various parts of a PLC with a picture.

Power supply

The power supply provides stable voltage to the PLC and other internal components by conventive the impute source power into voltages in it for the PLCs internal circuitry.

Central processing unit

Decentral process you need is also known as the processor. It is the brain of the PLC. It is a cute instructions, processes data and manages communication with other devices.

Input/outputs modules

Modules help in connecting of additional input or output devices to the PLC using a data cable. So, Instead of getting a new PLC in a case where there is an increase in the number of input and outputs terminals you just get a module as it is cost efficient.

Input modules receive signals from external devices like sensors, switches and transmitters etc, they are said to accept and convert signals from sensors into a logical signal while output modules convert control signals from the CPU into digital or analog value to manage output devices to convert signal construction. It provide the means of connecting the processor to the field device.

Communication Port

Communication ports also helps in the transfer of signal through the PLC to the computer in order industrial automation part like the variable frequency drive and human machine interface, etc.

Programming devices

Programming devices I used to develop modify and upload the control program to the PLC. This devices can be a laptop desktop computer or hand-held programmer.

Name Five Input and Output Electrical and Electronic Devices Operated by PLC.

| S/N | Input Devices | Output Devices |

|---|---|---|

| 1 | Thermocouples | Audible buzzers |

| 2 | Thermistor | Indicator light |

| 3 | Hand switches | Relay coil |

| 4 | Photoelectric sensors | Motor contractors |

| 5 | Strain guages | Solenoids |

Practical Reports

Data given:

• The power load for setting up an industry

= 10MW = (10 * 10^3)KW

=10,000KW

• Five 5KW and three 45KW three - phase motors; the total power of the motors will be:

=(5 * 5)KW + (3 * 45)KW

= 160KW

Now,

The total power load = Total power for setting up the industry + Total power of the motors needed to run the product in the industry

Therefore,

The total power load = 10,000KW + 160KW

= 10,160KW

Using the conversion formula:

KVA = KW/PF

Note:

Power factor(PF) is assumed to be 0.9 and KW = 10,160

Therefore,

KVA = 10,160/160

= 11,288.89KVA

~ 11,289KVA

Therefore, the transformer that will be needed will be a 12,000KVA(12MVA)

Assumed secondary voltage = 415V

Primary current is calculated thus:

Using the formula;

I = P/√3 * V(primary)

Where,

P = 11,289KW and primary voltage(V) = 11KV

I = 11,289/√3 * 11

I = 593.5A

So, the primary current is 593.5A

Secondary current is calculated thus:

Using the formula;

I = P/√3 * V(secondary)

Where,

P = 11,289KW and secondary voltage(V) = 415V = 0.415KV

I = 11,289/√3 * 0.415

I = 15,700A

So, the secondary current is 15,700A

So the transformer specification will be:

| Data | Readings |

|---|---|

| Transformer Rating | 12MVA(12,000KVA) |

| Primary voltage | 11KV |

| Secondary voltage | 415V |

| Primary current | 593.5A |

| Secondary current | 15,700A |

| Impedance | 6% |

| Cooling system | ONAN/ONAF |

| Frequency | 50/60Hz |

| Tap changer | ±5% to ± 10% |

| Efficiency | 98% |

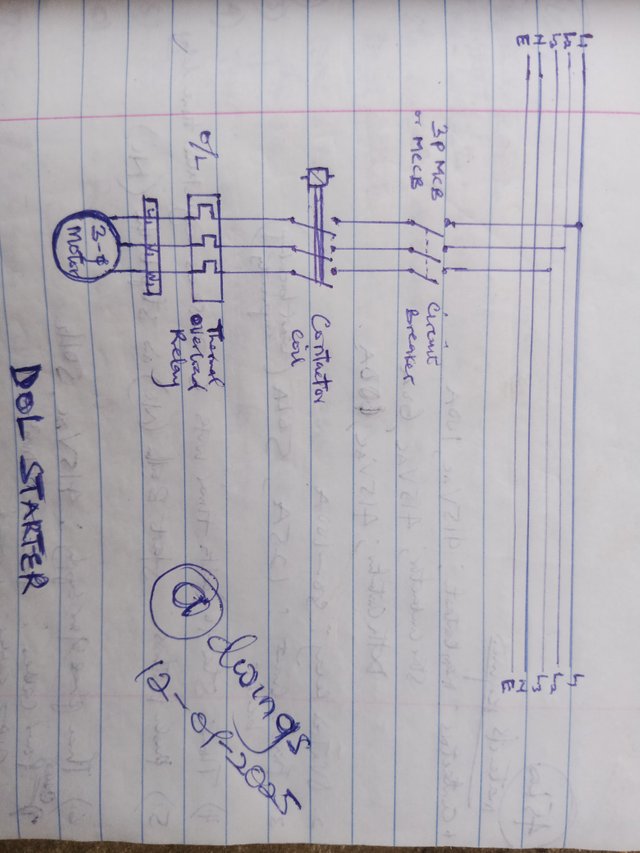

DOL starter is suitable for this motor because it converts the motor to a full supply voltage and enhances quick startup giving it a high efficiency. This motor of 5KW has a low starting current,so it doesn't need any significant voltage drop.

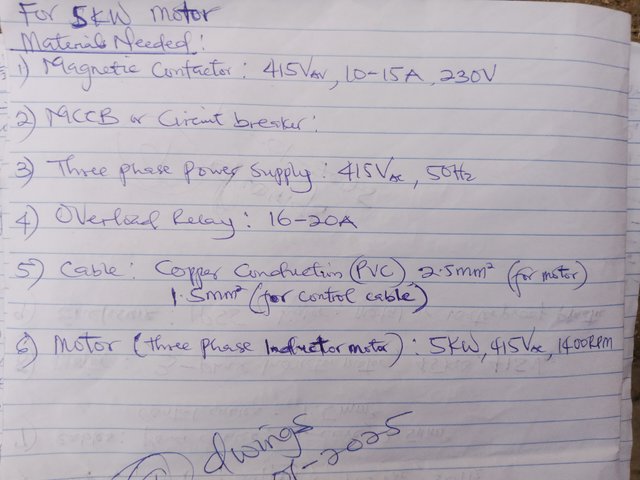

Materials needed for this starter include:

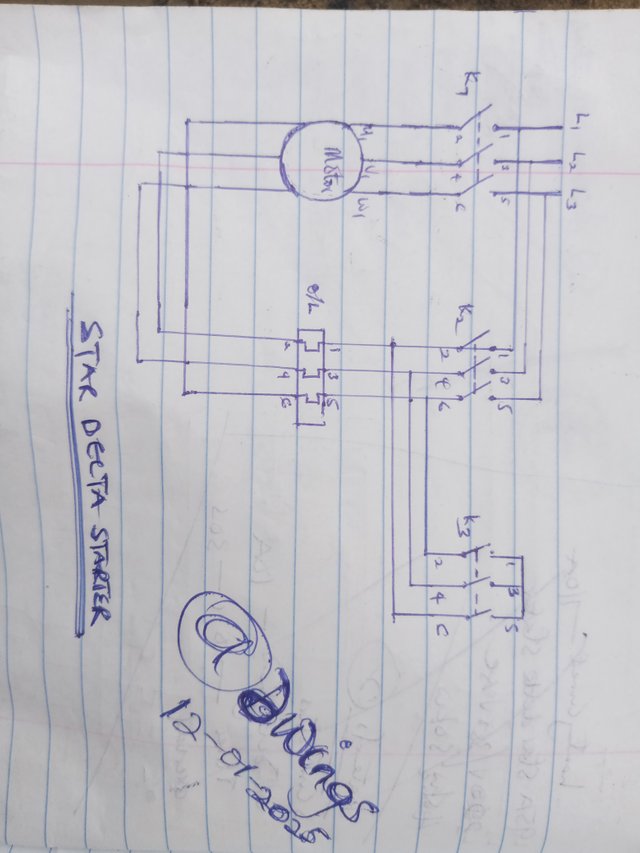

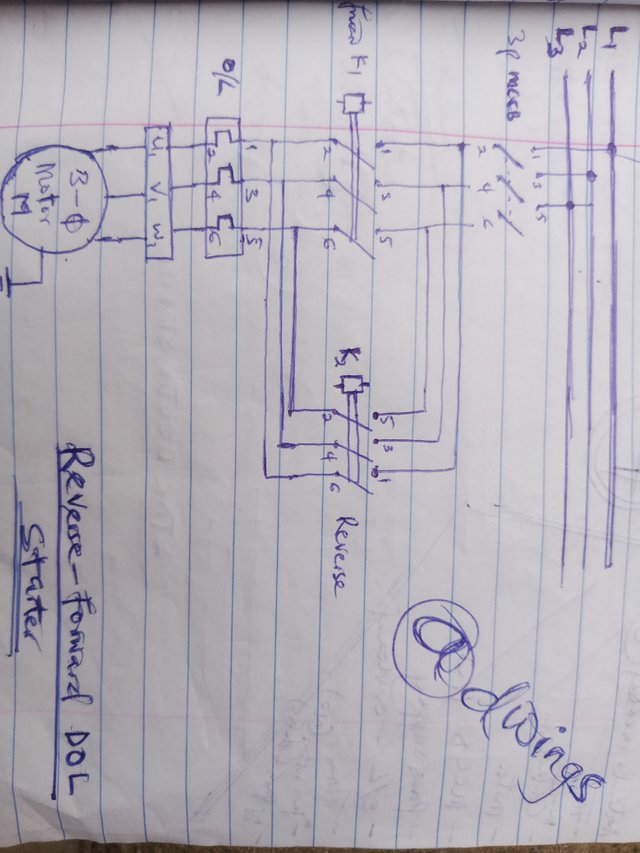

A star-delta starter is required as it will efficiently reduce the starting current, protecting the motor and electrical network. Other starter that can be employed in this scenario are Soft starter, Variable frequency drive starter, etc as using a DOL starter will stress the motor windings, creating a severe voltage drops. So, it is not advisable to use the DOL starter.

Materials needed for this starter include:

Star Delta starter is still recommended as it reduces the starting current to about 1/3 of the full load current minimizing stress on the motor and supply network thereby minimizing voltage drops.

Materials needed for this starter include:

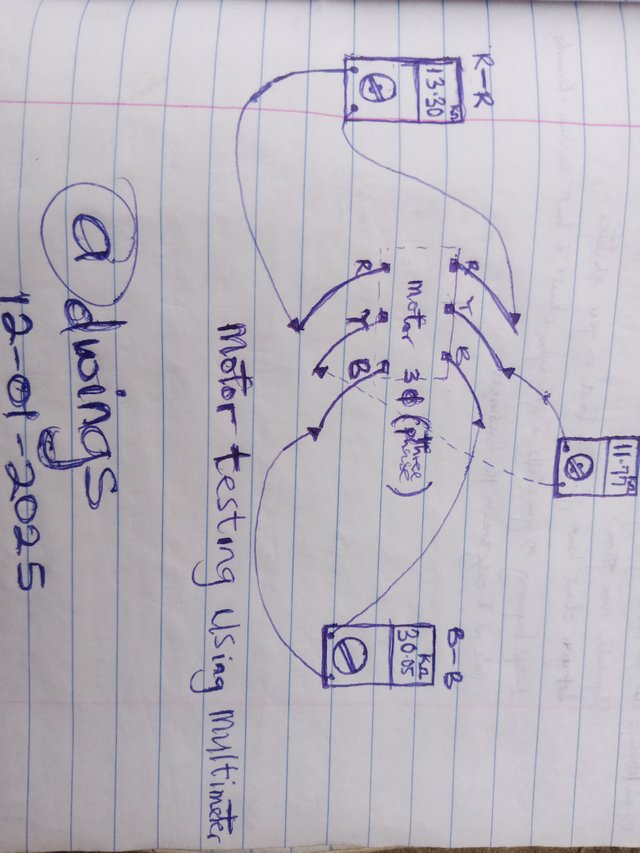

Review of the pictures of the motor checked with a multimeter

In the testing of a motor either the one operating using a Star connection or a Delta connection we will have to disconnect it from the three-phase power supply from my understanding. And these two connections have different ways of testing motors which operate based on their working principles.

From the pictures used for illustration in the lesson, it is obvious that the three-phase motor is bad based on the values obtained from each same color code terminal readings.

We are informed from the table that any same terminal readings(i.e Red to Red, Blue to Blue and Yellow to Yellow)of the motor that is beyond 10 ohms is depicted to be faulty.

I respectfully invite @bossj23 @nsijoro @basil20 and @ahsansharif to participate in this awesome steemit learning class and subsequent ones.

Dear, the second picture of your homework is taken from google which is against Steemit platform rules. You can quickly upload images from Steemit approved web links. I will wait some time for your reply or I will cancel your homework. thank you

I'm getting to know about this... I will effect the necessary correction with immediate effect... Thank you.