5 Ways To Produce A Seamless Garment

Seamless design without excessive joint points has always been an attractive speculative idea to an innovator, futurist, science fiction and streamlining enthusiast. And for a person who finds manual repetitive work such as sewing mind-numbingly daunting and far from a meditative activity.

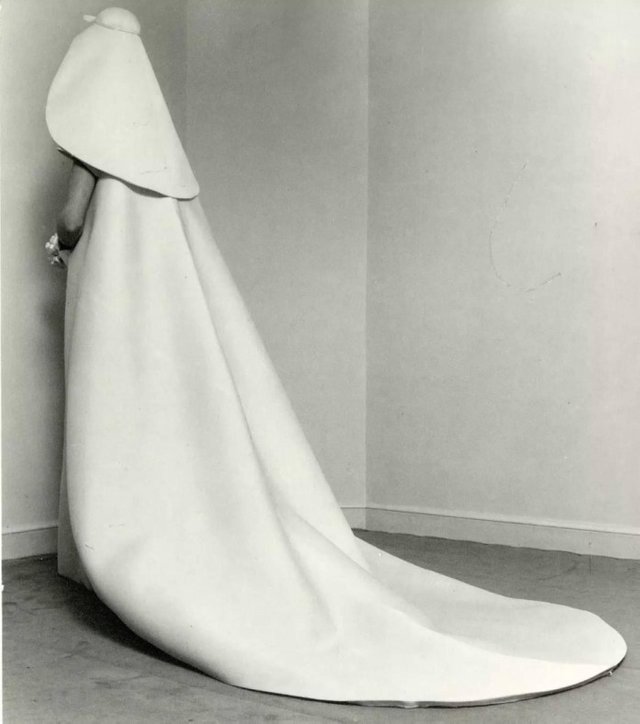

In the space-age era of 1960's this concept is encouraged by space explorations, and all things futuristic are penetrating into the design thought. Fashion seems obsessed with futuristic forms and new materials, and the seamless concept is in 1967. applied to a traditional garment - a famous wedding dress made by Balenciaga. The closed sculptural form has one seam only placed on the back, and to achieve this one has to think quite peculiarly - for those unacquainted with traditional tailoring, making a garment with one seam is like making a portrait without taking the hand of the paper.

Image source: 1granary.com

Balenciaga's space-age wedding dress with accompanying veil

Seamlessness is about minimalism, it is about a simplified production process of liquid forms, and it is a mark of unique intelligence. Here are the 5 ways how to make a 'seamless' garment.

Wraping

In 2010 an architect Julian Hakes creates a shoe applying the architectural logic of load distribution - shoe does not need the support by the whole length of the sole. His Mojito shoe wraps around the feet and provides support at the toes and the heels. Layers of carbon fibre are used for its production, meaning the shoe is strong and has the spring, with leather padding (Why, oh why the leaher, when is so perfectly futuristic?!) and rubber on the outside.

Image source: dezeen.com

Fun fact: ''Mojito'' shoe got its name because of the resemblance with a peeled lime

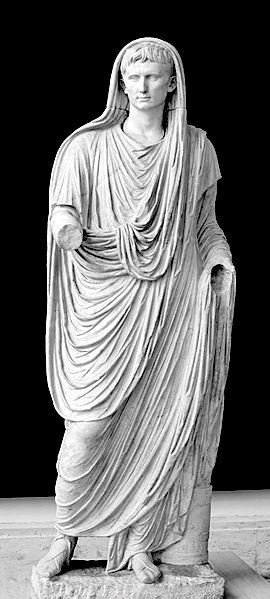

Wrapping is a very basic way of forming a garment. Ancient Romans are well known for their ceremonial robe toga, a mostly made in white wool, 4-6 meters long fabric that circulates draped over the shoulders and around the body. Without any fasteners, toga was held in position by the weight and friction of its fabric.

Emperor Augustus wears toga in capite velato manner (with covered head), practised in religious ceremonies.

Circular knitting or weaving

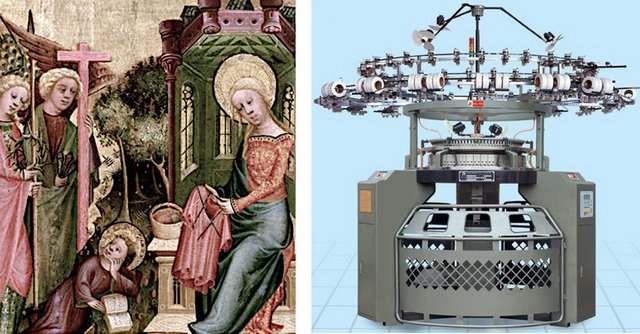

The Seamless Robe of Jesus (also called the Holy Robe) is according to the gospel of John worn by Jesus in time of the crucifixion. The robe was allegedly woven in one piece from the top down, without seams, and the soldiers refused to tear it in pieces as they did with his other garment. Instead, they cast lots to determine to whom it would belong. The Holy Seamless Robe therefore represents the unity of the Christian church.

More common that seamless weaving (I have never heard of such a thing until this story with Jesus), are seamless knits. A technique is old as knitting itself - hand knitting with four needles evolved in a circular machine knitting producing complete whole garments based on preprogrammed computer command. The product is a finished or semi-finished garment with no side seams.

Image source: textilelearner.blogspot.com

Circular knitting: then and now

Issey Miyake explored this method and made a garment out of one piece of tubular material containing a finished skirt, shirt or pants, which need only to be cut out along the faint outline. A-POC, an acronym for "a piece of cloth" is sold as a playful long tube of the jersey, where the weaving and joining is an integrated process, and it was then up to the customer to cut and shape it.

With this technique is possible to experiment with different types of yarn, like antimicrobial and hydrophilic or highly elastic and very fine micro-fibres, so these garments can conform smoothly to ones individual silhouette and allow for a more streamlined feel.

Tridimensional Printing

2010's hit, 3D printed clothes is a speciality of a Dutch designer Iris van Herpen. Her 3D print sculptural dresses were producing WOW effect then, and are getting a bit boring now. Technology is not so commercial at this stage, but soon it might come the time when all of us will be printing clothes at home. You can also choose a variety of polymers and choose a level of elasticity for particular points of the body like joints.

image source: www.rhinecapital.com

Iris van Herpen 3D garments

Glue

Performance attire company Dyne whose founder Christopher Bevans created the entire collection without stitch, using merely glue, even for applying the pockets. He said that this type of joining gives smoother lines, a lighter feel, and a sportier look. It is also good for waterproof clothes because stitches create little puncture holes that allow water to come through.

Garment in Form of Spray

Fabrican is a spray containing wet fibres that are forming a flexible, consistent material in process of drying. When sprayed directly on the body, it eliminates the problem of grading and it is easy to repair by simply applying a new spray layer to the damaged part.

...

So, from one stitch to non-stich, one might think about the following insight from I forgot who: ‘’While "no stitches" may at first seem counter-intuitive, seams are traditionally the weakest point of any garment.’’

The result is the more comfortable clothing of advanced performance with a simplified, seamless and fully integrated production system.