Engineers Have Developed a 3D Printing Process for Opaque Resin that is Ultra-Fast.

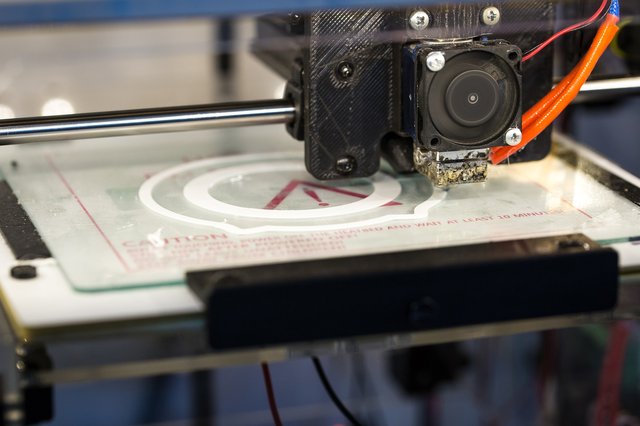

Engineers from EPFL's Laboratory of Applied Photonic Devices (LAPD) have created a resin 3D printer that can design items in a matter of seconds. It can make pieces with an opaque resin using a volumetric printing technology, which was previously impossible with this method.

There are various innovations centered on resin processes, and this team of engineers created a way to significantly speed up the printing process 5 years ago. The final product can take several hours to produce, and several manufacturers are working to improve the speed of their equipment. The engineers use a volumetric technique in this example. Professor Christophe Moser of EPFL explains: "We spin the resin after pouring it into a container." Then, at various angles, we beam light on the container, causing the resin to harden wherever the accumulated energy in the resin surpasses a certain threshold. It's a very precise method that can generate objects with the same resolution as traditional 3D printing."

In addition to obtaining a high-resolution part, the process is much faster. In fact, the engineers put their technology to the test and were able to print a small Yoda in just 20 seconds. The material utilized, though, is extremely intriguing: an opaque resin. Using such a resin in a volumetric process is quite difficult. Because light does not propagate smoothly, the quantity of energy required to harden the liquid resin is reduced. As a result, resolution suffers, making volumetric printing less appealing. Engineers set out to find a way around this problem by ensuring that light could pass through the resin in a straight line.

The initial step was to use a video camera to track the path of this light. After that, they used computer computations to compose the ray distortion. Following that, the 3D printer was designed to execute the calculations and correct the light's course during the printing process. The goal is to direct light to the right places in order to obtain enough energy to harden the resin.

Engineers intend to apply this method in the medical field, particularly in the creation of artificial arteries, which frequently necessitate the use of opaque resin. The next phase will be to combine many materials and raise the resolution from a tenth of a millimeter to a micrometer. We'll keep you up to date on any new advancements in the project!