How Does Engineer Design an Chemical Industry ?

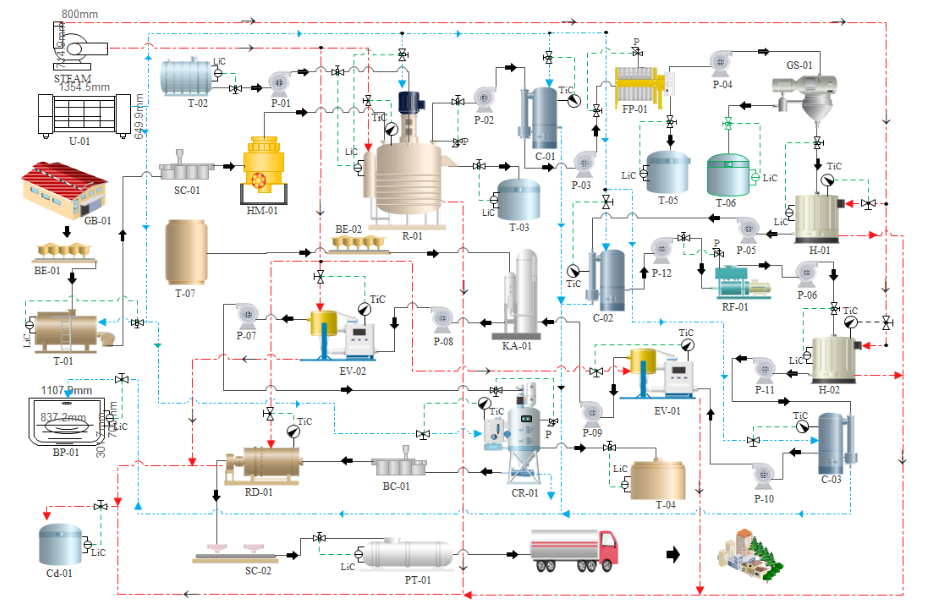

Flowsheet Enginering

Flowsheet Enginering

Calculating Raw Materials

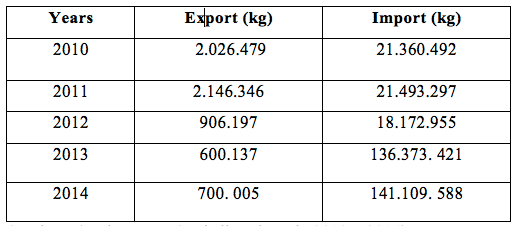

Determine a raw material to become new product estimated the raw materials and areas to achieve production target, For example, the manufacture of glucose from corn starch, the pre-design of this plant is the result of my own work to completion of my course in chemical engineering. The first thing we are doing is the analysis of raw materials that we will make the product and the area of raw materials are also easy for transportation. To know the production needs of plants that we design, we have to calculate the production in 5 years ago.

From some glucose description data mentioned beside, the magnitude of opportunity be able to increase amount of glucose production, with utilization of corn starch so as to increase development of human and economic resources of the State.

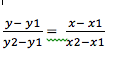

Where: x is the desired year ie 2015

- X1 is the year 2010

- X2 is the year 2011

- Y is the production you want to know

- Y1 is production in 2010

- Y2 is production in 2011

From data extrapolation of corn plantation production in Aceh in year 2015 estimated 2,745 ton/year, hence plan of corn starch processing factory with product capacity 12.000 ton / year with requirement of raw material 2,745 ton/year.

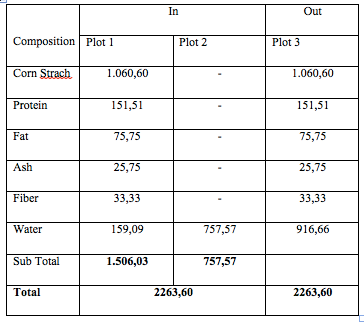

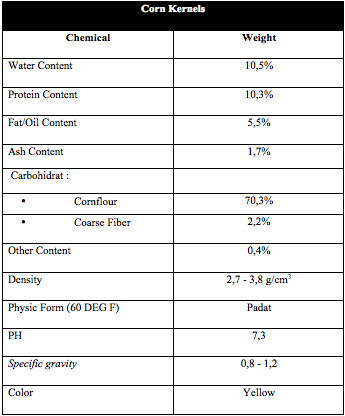

Chemical Content Analysis

Knowing the level of chemicals in a raw material, because the core of this raw material to be processed into a product, for example, Corn kernels are rich of carbohydrates. Most are on endospermium. Carbohydrate content can reach 80% of all dry seeds. Carbohydrates in starch form are generally a mixture of amylose and amylopectin. In sticky corn, most or all of its sticks are amylopectin. This difference does not have much effect on nutrient content, but more meaning in processing as food. Carbohydrate is a carbon, hydrogen and oxygen compound widely found in nature that has the empirical formula CH2O. Generally, carbohydrate sugars are divided into three groups, Monosaccharides, Disaccharide, Polysaccharides. Polysaccharides are composed of many single sugar molecules, most importantly besides disaccharides are cellulase having formulas C12H22O11 and starch (C6H10O5)8

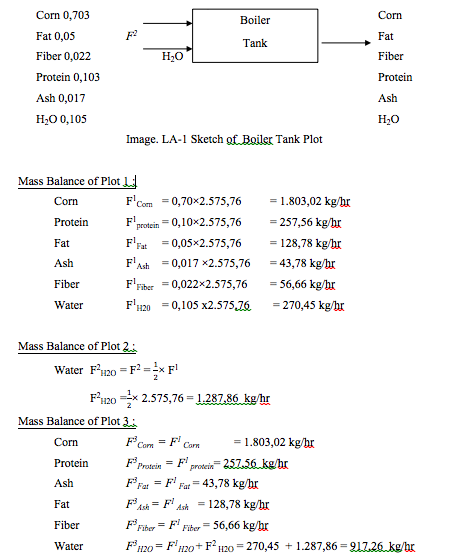

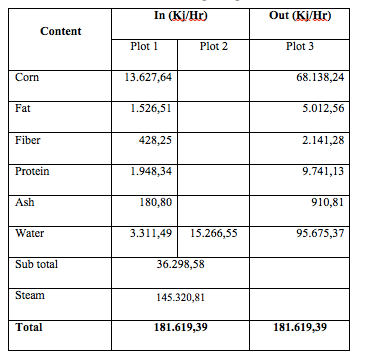

Calculation of Mass Balance

Mass balance calculation aims to knowing of energy needed on each instrument

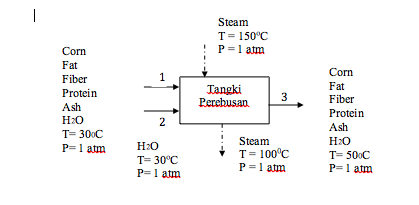

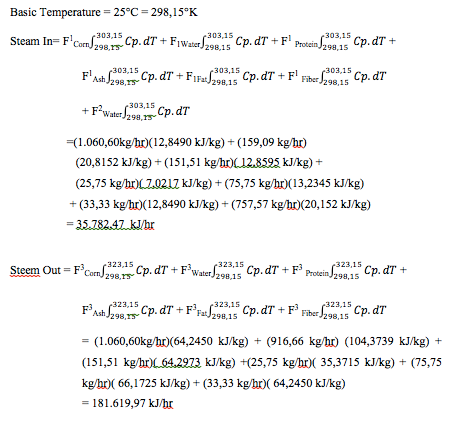

Calculation of Energy Balance

Enegy balance calculation aims to know the capacity required by the instrument to be operated in the industry.

The Equation

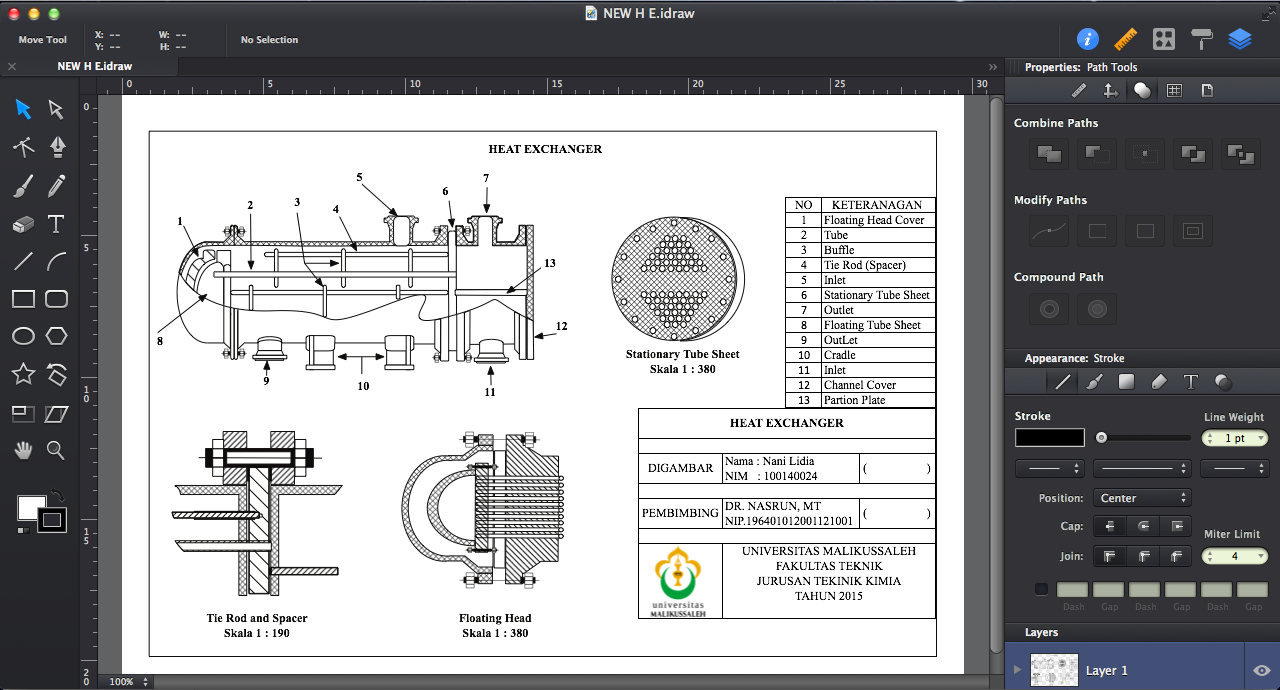

Instrument Speculation

An instrument uses as Heat Exchanger

Function: Where hydrolysis reaction occurs

Type: Mixed flow reactor

Shape: Vertical cylinder with base and ellipsoidal cover

Construction materials: Stainless steel SA-316 Grade C Amount: 1 unit

Capacity : Operating conditions

Temperature: 80 ° C

Pressure: 1 atm - Cylinders

Diameter: 1.1566 m

Height: 1,5421 m

Thickness: ½ in -

Closed Diameter: 1.1566 m

Height: 0.2891m

Thickness: ½ in

Utillity

Designing utilities to find out the capacity of electric current and water required in industrial operations.

Utilities are the main supporting units to facilitate the production process. Therefore, in order for the production process to continue continuously it must be supported by good utility tools and infrastructure. Based on its needs, the utility at the Corn Glucose making plant is as follows:

1. Steam supply unit (steam) 2. Water supply unit 3. Chemical supply unit 4. Unit of fuel provider 5. Electricity supply unit 6. Waste processing unit

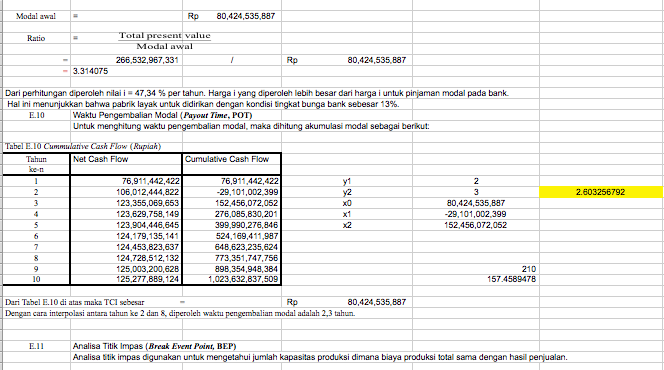

Economic Analysis

To evaluate the feasibility of the establishment of a factory and the level of income, the technical calculation is performed. Furthermore, it is also necessary to analyze the economic aspects and financing. From the analysis result, it is expected that various policies can be taken for proper direction. A factory design is deemed feasible to be established if it can operate under favorable conditions.

Various economic parameters are used as a guide to determine whether or not a factory is established and the level of income that is economically acceptable. These parameters include:

1. Capital investment (CI)

2. Total production cost (TC)

3. Profit Margin (PM)

4. Break Even Point (BEP)

5. Return on Return on Investment (ROI)

6. Payback Time (POT)

7. Internal Rate of Return (IRR)

(we can use this clashflow to analyst some investment of bitcoin mining either steem on steemit)

Disclaimer : All of the above data is sourced from the factory design of my scientific work that approved by my faculty and department of chemical engineering.

Flowsheet Design By My Self

Image Screenshoot from My Ms. Word and Ms.Excel

Support Scientist By Use #science tag or join @steemSTEM

Follow Me @jamhuery

One of the best engineering posts I've come up on Steemit. Thanks for the service mate! :)

welcome to join this amazing community, and thanks for your appreciation

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by jamhuery from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, and someguy123. The goal is to help Steemit grow by supporting Minnows and creating a social network. Please find us in the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you like what we're doing please upvote this comment so we can continue to build the community account that's supporting all members.

Congratulations @jamhuery! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOP@jamhuery got you a $0.82 @minnowbooster upgoat, nice! (Image: pixabay.com)

Want a boost? Click here to read more!

This post received a 4.0% upvote from @randowhale thanks to @jamhuery! For more information, click here!