Extrusion 3D Printing | Additive Manufacturing and 3D Printing

If you have any experience with 3D printing, it's probably with an extrusion 3D printer. Extrusion 3D printing involves building parts by laying down patterns of material filaments in layers. FDM (Fused Deposition Modeling) and FFF (Fused Filament Fabrication) are other terms for extrusion processes. Both are the same, even though FDM is used sparingly due to a copyright from 3D Printing company Stratasys.

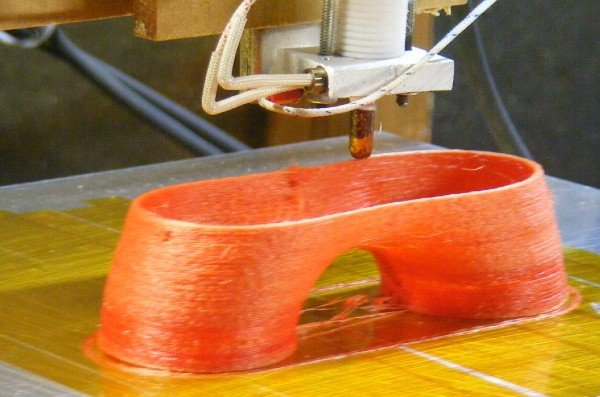

Usually, bulk material (typically a refill spool) is either melted or just deposited by forcing material through a nozzle. The nozzle moves in a computer controlled pattern to place material and build the part in layers. If the material was melted, the material is allowed to cool, and the material solidifies this way. Some processes might use chemical means to harden the material instead of thermal means.

Materials

Typically, thermoplastic is used. Polycarbonate (PC), and acrylonitrile butadiene styrene (ABS) form the basis of the plastics. PC-ABS is a combination of the plastics, and other plastics such as ASA are often used. Thermoplastics are amorphous, which means the melting temperature is not as distinct. For printers that heat plastic, this is useful because the plastics can be heated to a soft, but not totally liquid state that is easy to place. The plastic can be extruded through the print nozzle but still holds a general filament shape. Other materials, like ceramics, are capable of being used with more caveats.

Filament Difference

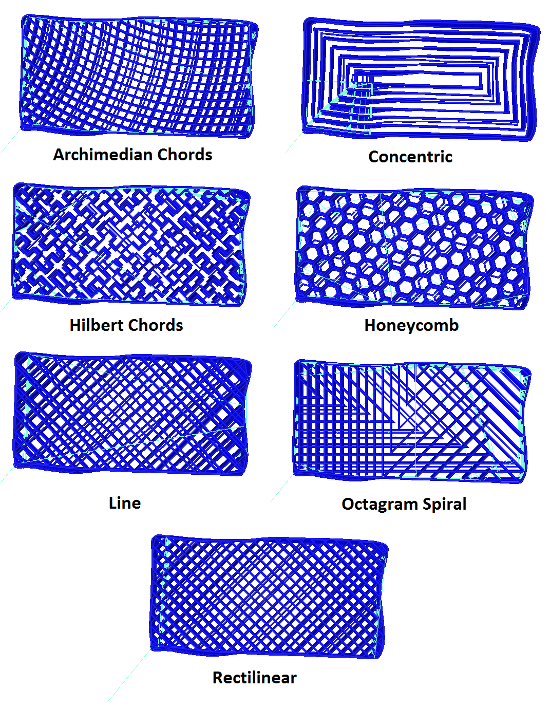

Because the filament is typically very thin, the way the material is laid down in a pattern is very important. As the material hardens, it might shrink. Therefore, the fill pattern, or how material is laid down, affects the part structure. If you need to fill a square layer with filament, there are many ways to accomplish this:

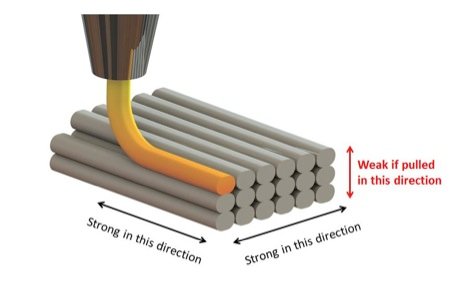

Printing with filaments in layers also shows a potential hurdle: different properties in different directions. Since you are relying on the filaments to stick together across layers, this can make the part weak in one direction in particular: the build layer direction.

Additionally, the offset between two intersecting filaments needs to be considered. The filaments have to be close enough to each other to bond, but if they are too close, the extra material builds up and can bunch up or grab onto the print nozzle, causing the print to be ruined or have a defect.

Still the Most Popular Process

For hobbyist and even some industry use, extrusion 3D printing is simpler and safer than other methods. Because the filament material can be placed with refill spools, extrusion 3D printing is more like 2D printing with paper. Unlike Vat Polymerization or Powder Bed Fusion, there's no liquid and power respectively to worry about containing or recycling.

THANKS DJANKY for a good introduction.

FDM process or also called FFF or other names is now very open source. Unless I am mistaken, all the key patents have expired (but maybe Stratasys has a copyright on FDM). In the recent RAPID trade show in Pittsburg, PA, I saw no less than 15 machine manufacturers for this technology with at least 5 offering machines for INDUSTRIAL (not hobbist/maker) use. Many of these machines are with price points less than $10k USD and offer very diverse features and large (by historical standards) build sizes. 4

Also now, an offshoot of this technology includes using a pellet extruder instead of a filament which allows use of many engineering resins (injection molding grades mostly). This area is fertile for development. If enough people are interested, I can write a detailed post about this evolving technology which can be very exciting.

Thanks for the post! I can tell you that I've been thinking of getting something 3D printed for my business, but then I understood that it won't work just as good as I thought. Instead, I've decided to get an acrylic signage singapore , and it tuned out to be a great decision, so I wasn't disappointed at all.

The more I read about additive technologies, the more I understand that printing itself is only the first step, and the real "magic" happens at the post-processing stage. But here's the question: how to properly build a quality control system? After all, each processing (grinding, thermal cycles, HIP) changes the properties of the part, and if something is done wrong, the output is completely different from what was designed. Has anyone done a full testing cycle for themselves: printing + different post-processing options + comparison of properties? It seems to me that this is where the main problem of the industry's development lies - without standardization of post-processing, we will not be able to achieve mass application. What do you think?

Here you asked the most important question. I myself was racking my brains over which processes really work and which are just marketing. And just on the Tech Met website I found technical documents with figures and measurements for different alloys. Honestly, for me it was a revelation, because I got access to specific data: how fatigue changes, how roughness improves, etc. I think information about additive manufacturing post processing will help you avoid mistakes and save time, because you will immediately understand which processes really give results.