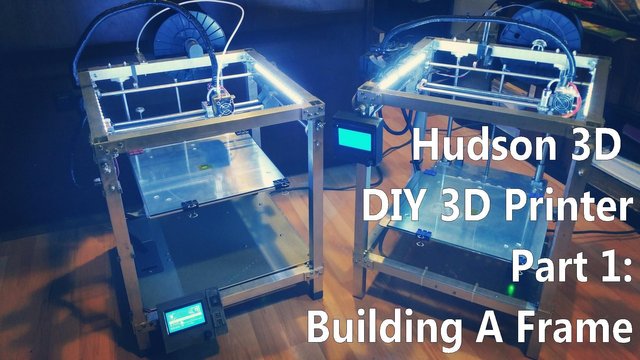

DIY 3D Printer Build Video Tutorial

Now you can build your own Hudson 3D Printer. This printer build can be accomplished with locally sourced components and some online purchases. This is an excellent project to do in an educational setting and gives you a better understanding of how a 3D printer works. The tutorial should be easy enough for most to follow and you can always ask questions in the comments here or on the video page to get extra help or clarification.

Videos In This Tutorial Series:

Part 1 - Building A Frame: https://steemit.com/dtube/@bigdogmarco/y173i0td

Part 2 - Building A Frame: https://steemit.com/dtube/@bigdogmarco/jbvfs80u

Part 3 - Z Axis Linear Rods: https://steemit.com/dtube/@bigdogmarco/suihoeeh

Part 4 - Y Axis Linear Rods: https://steemit.com/dtube/@bigdogmarco/xh63llxy

Part 5 - X Axis Printed Parts: https://steemit.com/dtube/@bigdogmarco/7lh19o7u

Part 6 - X Axis Linear Rods: https://steemit.com/dtube/@bigdogmarco/b5ujvbn1

Part 7 - Extruder Carriage: https://steemit.com/dtube/@bigdogmarco/92ep8a33

Part 8 - Y Axis Transmission Rod: https://steemit.com/dtube/@bigdogmarco/kzkrd2wp

Part 9 - Z Axis Threaded Rod: https://steemit.com/dtube/@bigdogmarco/je49zt0l

Part 10 - Y Axis Transmission Rod: https://steemit.com/dtube/@bigdogmarco/mmfdqr29

Part 11 - Timing Pulleys: https://steemit.com/dtube/@bigdogmarco/yfztc8ds

Part 12 - Timing Belts: https://steemit.com/dtube/@bigdogmarco/1np0qeh3

Part 13 - Heated Print Bed: https://steemit.com/dtube/@bigdogmarco/py7kv0vb

Part 14 - Power Supply: https://steemit.com/dtube/@bigdogmarco/4tychla1

Part 15 - RAMPS & Firmware: https://steemit.com/dtube/@bigdogmarco/pjzqnly0

Part 16 - ABL Sensor Bracket: https://steemit.com/dtube/@bigdogmarco/bea4xaba

Part 17 - ABL Sensor & Firmware: https://steemit.com/dtube/@bigdogmarco/ke5nihpf

Part 18 - Functional Upgrades: https://steemit.com/dtube/@bigdogmarco/82g5m01k

This 3D printer as designed has the following specs:

Machine dimensions: Width: 44.5cm, Height:50.8cm, Depth: 45.7cm

Print dimensions: X axis: 292mm, Y axis: 250mm, Z axis: 260mm

Z minimum layer height: 0.05mm (50 microns) possible, 0.10mm (100 microns) optimal

Print Speed: 70mm/s (conservative setting, higher speed possible through firmware config)

Tools that you will need:

– Metal cutting tools

– Drill/driver

– Hand tools (precision screw drivers, allen wrench set, adjustable wrench or socket set)

– Filing/sanding tools

– Soldering iron

– Wire cutters/strippers

Other helpful tools that will make this easier:

– Dremel type rotary tool

– Drill press

– Hole saw

– Tube cutter

– Forceps/Tweezers

– Access to a 3D Printer or 3D printing service for printed parts

Bill of Materials (parts list), firmware and wiring diagrams can be downloaded here: http://bit.ly/hudson3dfiles

You will also need the following .stl files for the minimum printed parts required for this build:

XY Axis Mounts STL file:

http://www.printcisely.com/object:24:hudson_3d_xy_axis_mounts

Extruder Carriage STL file:

http://www.printcisely.com/object:23:hudson_3d_extruder_carriage_for_mk8_or_mk9

Enjoy the vote and reward!