The Essential Components of an Efficient Crushing Machine

The mining, construction, and aggregate industries rely on wear parts and liners to ensure that crushing equipment remains efficient and long-lasting. Since crushers are subjected to constant impact, friction, and abrasion, wear-resistant components are essential. Crushing operations are more efficient, have less downtime, and are more productive when high-quality wear parts are used.

It is essential to select the right Crusher Wear Parts supply in order to optimize crusher performance. The durability and effectiveness of wear parts are determined by the materials, design, and manufacturing processes used. There are several common materials used in wear parts, including manganese steel, alloy steel, and high-chromium iron. Each has its own advantages. The high impact resistance and work-hardening properties of manganese steel, for example, make it ideal for crushing hard and abrasive materials.

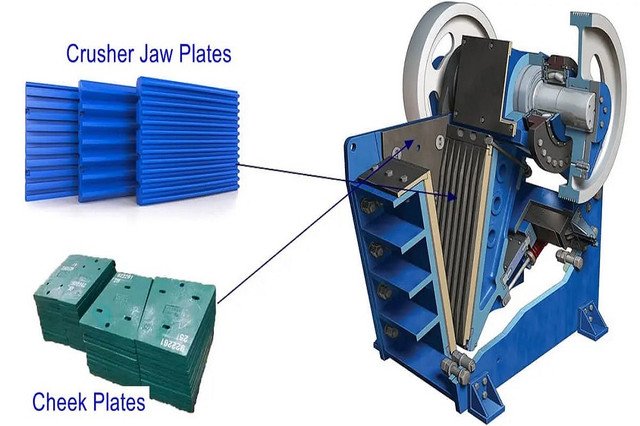

It is necessary to break down rocks and ores into smaller, manageable sizes with the help of the wear parts of crushers, including jaw plates, concaves, mantles, hammers, blow bars, and impact plates. Jaw plates are essential in jaw crushers, providing the crushing surface required to break large stones. Cone crushers use concave and mantle chambers to grind materials into finer particles. Impact crushers, on the other hand, require blow bars and impact plates to absorb shock and disperse energy effectively.

Manufacturing technologies have improved the quality and durability of crusher wear parts significantly. In order to enhance wear resistance and extend service life, many manufacturers now use precision casting techniques, heat treatment, and surface hardening. The wear-resistant casting manufacturers in China have gained worldwide recognition for producing high-quality wear parts for heavy-duty applications. They ensure superior wear resistance, toughness, and performance in challenging crushing environments through advanced metallurgy and state-of-the-art manufacturing processes.

Keeping crushing operations running smoothly requires proper maintenance and timely replacement of crusher wear parts. Identifying signs of wear, such as cracks, deformations, and material loss, allows operators to replace wear parts before they fail altogether. By replacing wear components and lubricating them, preventive maintenance strategies can significantly extend their lifespans and reduce operational costs.

The demand for crusher wear parts supply continues to grow as industries expand and require efficient crushing solutions. To meet this demand, suppliers offer customized wear parts tailored to specific crushing applications. For different rock types and operating conditions, different material compositions, varying hardness levels, and unique designs can be customized. Investing in customized wear parts ensures long-term efficiency and cost-effectiveness.

Wear parts manufacturers have also been influenced by sustainability and environmental concerns. In order to reduce waste and emissions, many manufacturers are focusing on producing eco-friendly wear parts using recyclable materials and optimizing production processes. The industry is also exploring advanced coatings and composite materials that minimize the impact on the environment while providing superior wear resistance. Wear parts industry practices contribute to reducing mining and construction's carbon footprint. Get more info about China Wear-resistant Casting.

The wear-resistant casting industry in China plays a significant role in supplying durable wear parts around the world. As a result of their expertise in producing high-performance castings, they have become the preferred choice for businesses looking for reliable and cost-effective wear parts for crushers. These companies adopt advanced manufacturing techniques and strict quality control measures to ensure their products meet international standards and deliver exceptional performance.

To summarize, crusher wear parts and liners are essential components in crushing, influencing productivity, efficiency, and operational costs. Improved performance and longevity of crushers can be achieved through the selection of high-quality wear parts, proper maintenance, and advances in material technology. In order to meet the needs of a variety of industries, manufacturers and suppliers must continue innovating. For efficient and profitable crushing operations, investing in durable and well-designed crusher wear parts from local manufacturers or China wear-resistant casting suppliers is essential.