PT Arun NGL [Natural Gas] Converts Earth's Abdominal Contents Aceh #The Aceh Traffic

Image PT Arun NLG located in Blang Lancang Lhokseumawe City, on October 24, 1971, natural gas contained in Gampong (village) Arun was found with estimated reserves of 17.1 trillion cubic feet.

All Acehnese also know that PT Arun is a giant gas company in Aceh, but they do not know that PT Arun also extorted all the earth's contents of gas, condensate, sulfur, mercury and others.

It was the 73rd day since an exploration trial led by Bob Graves, chief executive of Mobil Oil in Aceh, began. In 1972 found offshore natural gas resources in the North Sumatra Offshore (NSO) field located in the Malacca Strait at a distance of about 107.6 km from the PT Arun refinery in Blang Lancang.

Furthermore, in 1998, NSO project "A" was completed which was covered by gas processing unit for offshore facilities and in PT Arun. The facility is built to process 450 MMSCFD of natural gas from offshore as additional raw materials of natural gas from the Lunokon fields of the aruns are dwindling. On 16 March 1974, PT Arun was established as an operator company.

<a href=".http://www.acehtraffic.com/2012/04/pt-arun-langgar-uu-sampah-hidrokarbon.html "http://www.acehtraffic.com/2012/04/pt-arun-langgar-uu-sampah-hidrokarbon.html rel="nofollow noopener">Image The company was recently inaugurated by President Soeharto on September 19, 1978 after successfully exporting the first condensate to Japan (October 14, 1977). The shareholders of the company are held by Pertamina (55%), Exxon Mobil (30%), and Japan Indonesia LNG Company (JILCO 15%).

According to electronic measurement data through films taken in the field and analyzed at Mobil Oil's analysis center in Dallas, USA, Arun gas field is located within a layer of limestone at a depth of 10,000 feet (3,048 meters).

The gas content reaches 17.1 trillion cubic feet with a pressure of 499 kg / cm, temperature 177 ° C, and a thickness of 300 meters. The amount is expected to supply six units of processing kitchen (train) with a capacity of 300 million SCFD (Standard Cubic Feet Day) for a period of 20 years.

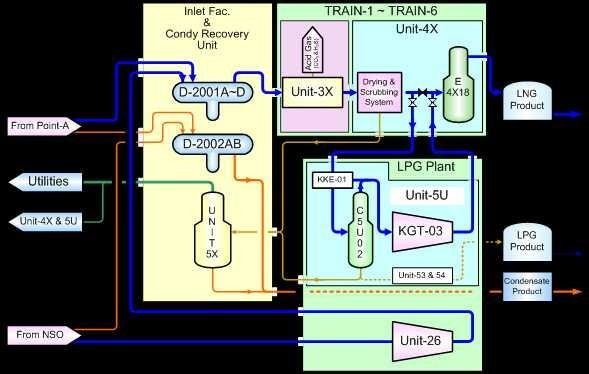

The gas field consists of four (4) clusters of gas and condensate, then gas and condensate are sent to the collection unit at Point "A" which is then sent to the Arun LNG plant by pipeline: Gas uses 42 inch diameter pipe.

Condensate uses 16 inch diameter pipe. LPG propane uses 20 inch diameter pipe. The Arun LNG plant in Blang Lancang covers an area of 271 ha with a length of 1.7 km and a width of 1.5 km and is completed with a special port for transporting its production.

Arun LNG refinery is equipped with 2 LNG ports for delivery of its products to buyer country, while for condensate delivery comes with 2 loading facilities, Single Point Mooring (SPM) and Multi Buoy Mooring (MBM). The condensate products are exported to many countries such as Japan, Singapore, America, Australia, France and New Zealand.

Image At the start of operation, the Arun refinery only produces LNG and condensate. The product is then carried out by utilizing the propane and butane gas components contained in the feed gas.

On July 15, 1986, a plan for the construction of a refinery of LPG, by PERTAMINA and a buyer from a Japanese state, which had previously been investigated for refineries and natural gas composition for the development of the products carried out, did not interfere with the quality and quantity of LNG production.

The construction of the LPG refinery started on 24 February 1987, based on a contract agreed by PERTAMINA and JGC Corporated as the main contractor, under the supervision of PLLP (PERTAMINA LNG-LPG Project). The construction site is chauffeured with an earlier LNG plant.

Development is done in three stages. The first construction was completed in February 1987 and completed in June 1988. The second phase was completed in October 1988 and the third phase was completed in December 1988 and the initial shipment of LPG products on August 2, 1988 to Japan.

In 1998, in accordance with its contract, LPG production was suspended, but the refinery remained in operation to maintain the balance of the gas feed composition to be liquefied in Unit 4X.

With time and reduced natural gas reserves at point-A, EMOI again found offshore gas reserves, called the North Sumatera Offshore (NSO).

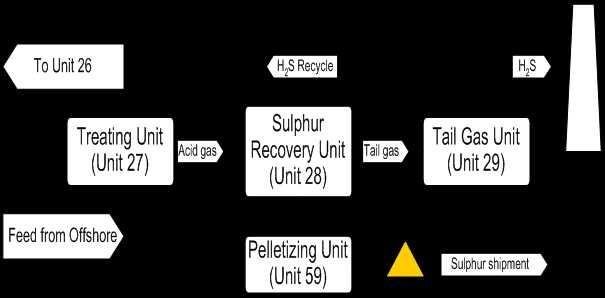

Image But this gas reserve contains many sulfur compounds (H2S) that interfere with the liquefaction process of natural gas. So in 1997 the NSO plant began to be built and operated in 1999 with the aim of purifying the feed to be relatively equal to the gas feed originating from the A-point and producing sulfur as a by-product which is also worth selling.

Image The Arun LNG plant has dozens of major and support units, starting from units in the Inlet Facilities to shipping units.

Image In general the task of the process at the Arun LNG plant, Receiving gas and condensate from point-A (Lhoksukon) and NSO fields. Purify and process gas feeds into LNG products according to specifications. Storing, shipping LNG, condensate, sulfur, mercury and other B3 waste products are also valuable.

Image Usage of Sulfur Product Mainly for fertilizer factory, for making SC2, just as good as sulfuric acid (Sulfuric Acid), Fabric base material, Cement mixed material, Material of other adhesive material.

Image So do not think if PT Arun NLG only produce gas and say "no profit this year" to avoid the public demand for PT Arun Transparent to mention the total nominal amount of CSR every year.

Nevertheless, the gas giant is now predicted to almost complete its history in 2014, anticipating that all the elite pertamina and crew of PT Arun continue to work to switch the functions of the giant tubes into the oil and gas storage terminals.