Carbon Fiber Tubes: Versatility and Innovation

By combining their unparalleled strength-to-weight ratio and dynamic engineering applications, carbon fiber tubes have carved a niche for themselves in the field of modern materials. As a result of weaving carbon filaments into a fabric and curing it with a resin, these composite marvels form lightweight yet incredibly durable tubes that serve a variety of industrial, commercial, and consumer applications. From aerospace components to sports equipment, carbon fiber tubes have evolved through a fascinating combination of material science and manufacturing innovation. Due to their functional adaptability, variations such as special-shaped carbon fiber tube designs and large diameter carbon fiber tubes have gained significant popularity.

Carbon fiber tubes are primarily attractive because of their exceptional mechanical properties. When compared to traditional materials like aluminum or steel, carbon fiber is lighter and stronger per unit weight. For this reason, carbon fiber tubes are preferred in industries like aviation, marine, and automotive where weight savings are important. These tubes are used by aircraft manufacturers to reduce fuel consumption without compromising structural integrity, for example. Carbon fiber products are often used to enhance the speed and maneuverability of racing cars, including aircraft frames, roll cages, and suspension arms.

Special-shaped carbon fiber tubes are becoming increasingly popular due to the demand for more customized shapes. Tubes of this kind are often molded into squares, ovals, or even triangular shapes to fit specific structural requirements. In robotics, drone manufacturing, and advanced engineering prototypes, special-shaped tubes are particularly useful when conventional tube shapes are not suitable. A key factor in its growing demand across disciplines is its ability to be molded into virtually any profile while retaining its strength and lightweight properties.

One other development that has significantly widened the application scope of carbon fiber is the use of large diameter tubes. In applications involving large-scale mechanical structures or industrial machines that endure substantial mechanical loads, these tubes are often required. The ability of large diameter tubes to resist deformation while maintaining a low mass makes them ideal for telescopic systems, conveyor shafts, wind turbine blades, and heavy-duty camera rigs, for example. Furthermore, their resistance to corrosion and thermal expansion make them particularly suitable for extreme environmental conditions.

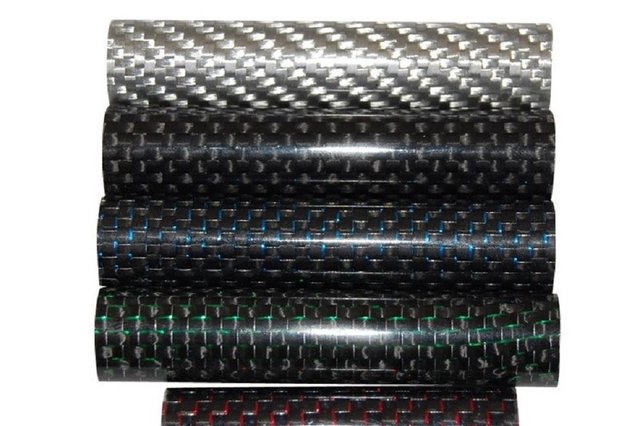

Carbon fiber tubes can also be customized for aesthetic and surface properties. They can be manufactured with different weaves, finishes, and colors, giving them a sleek and modern look that appeals to luxury product designers. In addition to its performance advantages, carbon fiber tubes are also used in high-end bicycle frames, camera equipment, and musical instruments such as violin bows and drum shells.

A Carbon Fiber Water Fed Poles has revolutionized the design of equipment in the sports and recreation industries. Incorporating carbon fiber into products has improved the user experience and performance of products ranging from golf club shafts to tent poles to kayak paddles. Carbon fiber-based tools minimize fatigue without sacrificing strength or control, making them popular with athletes and outdoor enthusiasts. Even small differences in equipment performance can make a big difference in competitive sports.

Using carbon fiber tubes has also transformed the medical sector. Due to its radiolucency (avoidance of X-rays and other imaging technology), carbon fiber can be used in surgical tables, diagnostic equipment arms, and orthotic devices. Unlike metal, carbon fiber does not interfere with imaging clarity, ensuring accurate diagnosis and effective treatment. The material is also biocompatible and hygienic enough to withstand repeated sterilization and prolonged human contact.

As innovation accelerates, Carbon Fiber Products are increasingly playing a crucial role in renewable energy solutions. Wind turbines, for instance, increasingly rely on carbon fiber tubes for both the nacelle structure and blade construction. A carbon fiber component's reduced weight and increased rigidity enhances wind turbine long-term operational efficiency. Performance benefits translate to higher energy output and lower maintenance costs, which contribute to sustainability goals.

Carbon fiber tubes serve as essential reinforcement materials in bridges, tunnels, and high-rise buildings. The emphasis on efficiency and strength is evident in the construction and civil engineering sectors as well. Retrofitting aging structures with carbon fiber components can dramatically extend their life without adding significant weight. Compared to traditional steel, carbon fiber is noncorrosive, which stands out especially in marine and humid environments, where steel degrades over time.

Furthermore, Carbon Fiber Products are adaptable to meet the rigorous demands of defense and aerospace technologies, making them ideal for defense and aerospace applications. In order to ensure reliability in mission-critical environments, lightweight drone bodies, satellite supports, and advanced weaponry systems use carbon fiber tubes. Under high-pressure conditions, they are relied upon by the military for their ability to absorb shock, resist vibration, and maintain integrity. This confirms the material's unsurpassed versatility once more.

The manufacturing process of carbon fiber tubes is also an area rich in technological advancement. Several techniques are used to produce tubes with precise characteristics. These include autoclave curing, filament winding, pultrusion, and roll wrapping. In addition to offering excellent surface finish and consistency, filament winding is ideal for high-strength needs. Automation and precision engineering enable manufacturers to create tubes with tight tolerances, complex geometries, and reliable mechanical properties.

As industries seek sustainable materials, carbon fiber tubes are being increasingly highlighted for their recyclability and long service life. Environmental consciousness is another important aspect of modern carbon fiber production. While recycling carbon fiber is more challenging than recycling metals, innovations in thermoplastic resin matrixes and energy-efficient curing processes are reducing its environmental footprint. Investing in carbon fiber tubes proves to be a sustainable investment where longevity and performance matter more than initial cost.

Nanotechnology, hybrid composites, and AI-assisted design are paving the way for better and more efficient carbon fiber solutions in the future. Technology, healthcare, architecture, and beyond will all benefit from both special-shaped carbon fiber tubes and large diameter carbon fiber tubes as demand increases for materials that have performance and elegance.

Ultimately, carbon fiber tubes represent more than just an engineering material; they are a convergence of art, science, and design. They are present in almost every innovative sector and continue to expand as new demands arise. The precision of medical instruments and the monumental scale of infrastructure projects are both being redefined by carbon fiber tubes. With industries continuing to adopt and adapt carbon fiber technologies, the future of these remarkable tubes is not only promising, but limitless.