Need of holes in disc brake

1: Compositions in the disc material is the important factor.generelly CI,graded CI,SS with Nicrome plating.

2: disc rotors having holes are generelly of the materials CI,SS. as you know that the friction between the caliper and the disc surface rases so suddenly that actually from room temprature to 200C within the few seconds. so the heat dissapiation rate should have to be high enough to cool down the disc to avoid the deformation or fatigue failure of the disc.

3: now by providing the holes on the disc rotor it actually increase the rate of heat dissapiation by convection. as transient heat phenomena.

4: the more surface area the heat rejection rate will be high,but the disc is a part which is very compact and space bound. so it is better to provide the holes to increase the surface contact between the disc and the surrounding to increase the convection.

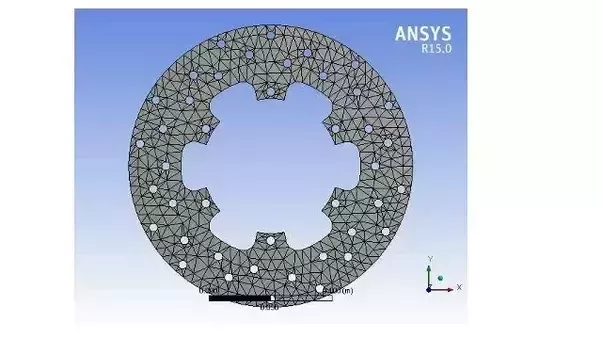

- as you can see the cad model of generel disc having holes

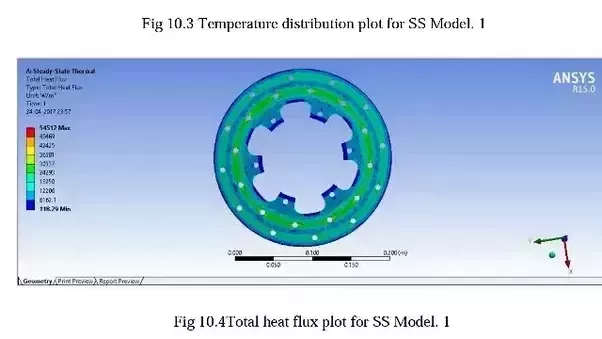

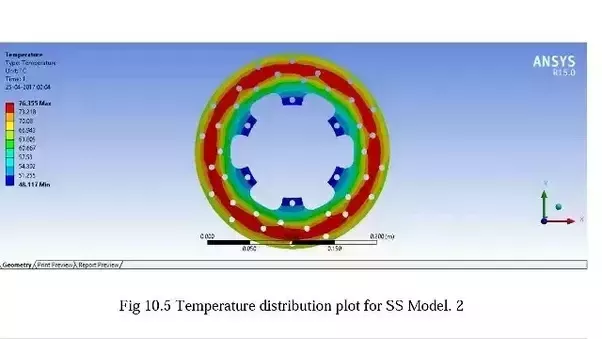

now we can see the temprature variation of the disc after performance.

before application of brakes i.e. at RT.

after application of the calliper on disc

A: now in case of 4wheeler the total surface area and the width of the disc rotor are enough to brake the temprature variations thats why there is no need to provide the holes on the disc.

B: in maximum cases ventilation type disc rootors are used in 4wheeler.

Source: Ansys Workbench 15.0.10(student edition)

Image: my black book and google images

for the black book go to the link:https://drive.google.com/file/d/0B5QxmR7aShpTYjVvWG1ZRmJSRjQ/view

for more details visit to quora

https://www.quora.com/Why-do-disc-brake-have-holes

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.quora.com/Why-do-disc-brake-have-holes