The future of biofuels

In the efforts to decarbonize the transportation industry, vehicles with varying degrees of electrification get most of the attention. But liquid fuels will predominate a while longer thanks to the delivery infrastructure circling the globe, dispensing fuels that contain significantly more energy per kg than batteries. That leaves a gap for a clean liquid fuel which is quietly being filled with biofuels. They are clearly controversial, but are they getting the respect they deserve? Given how much is at stake here, perhaps it’s time to take a closer look…

In the efforts to decarbonize the transportation sector, vehicles with varying degrees of electrification get most of the attention. But liquid fuels will predominate a while longer thanks to the delivery infrastructure circling the globe, dispensing fuels that contain significantly more energy per kg than batteries.

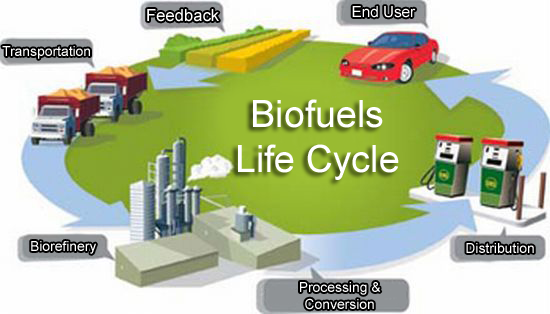

That leaves a gap for a clean liquid fuel which is quietly being filled with biofuels. According to the Renewable Fuels Association, biofuels have eliminated 232 million metric tonnes (255 short tones) of carbon, the equivalent of taking 5 million cars off the road since 2007. Yet, it is reportedly not even being mentioned by the US delegation at the COP21 in Paris. Biofuels are clearly controversial, but are they getting the respect they deserve? Given how much is at stake here, perhaps it’s time to take a closer look.

First-generation biofuel, also known as starch-based ethanol, represents the vast majority of biofuel that is being added, as a 10% blend, into gasoline today. For the most part, in the US, it is derived from corn. Corn sugars are distilled into ethanol the same way that whiskey is made.

At present, corn production volumes have grown enormously, as has the efficiency of conversion. The supply chain is well prepared to keep pace with increasing goals. However, the distribution infrastructure has not kept pace, citing concerns about a blend wall.

Corn ethanol has a lot of detractors with a variety of objections: everything from the fact that it’s a big government program, to opponents of big Ag on environmental grounds, to petroleum interests who see it as a competitor. But when all is said and done, corn ethanol, is the first step in a journey that will lead to clean, renewable liquid fuels that can play an enormous role in rapidly reducing carbon emissions.

Here are a few things that are not commonly known about ethanol. Ethanol has a very high octane rating. This means that blending ethanol into gasoline eliminates the need to blend in costlier and more toxic additives to raise the octane level to the required minimum of 87, a fact overlooked in most cost comparisons.

While ethanol contains less energy per gallon than gasoline, its high octane rating actually allows it to generate more power in an engine with a high compression ratio. That is why Formula 1 racing cars use ethanol as their fuel of choice. Unfortunately, those engines cannot run regular gasoline without harmful “knocking.” As Wolfgang Warnecke, Shell’s Chief Scientist for Mobility said, “As engine engineers, what we’d like to see is an engine that can vary its compression ratio. That way, depending on the fuel you are running, the compression ratio would adapt.” No such engine is yet on the market.

Those concerned that using corn for fuel could be taking food off the table may not realize that only the starch from the corn is used. The protein fraction, which is 40% of the corn, is returned as animal feed known as distiller’s dry grain (DDG).

Newer processes also separate out corn oil, which can be used for food or to make biodiesel. As the levels of corn being produced increase to keep pace with increasing gasoline consumption, more of these food products also become available. Says Jack Rogers, Biofuel Global Marketing Manager for Novozymes, a Danish producer of enzymes used in ethanol production, “People and animals are starch rich and protein poor.”

While people argue that when all the energy required to grow corn is factored in, corn ethanol is barely net positive; that equation continues to improve as both farm productivity and conversion efficiency grow (thanks to high performance enzymes). Says Rogers, “since 2005, the number of gallons of ethanol per acre, has increased from 409.7 to 489, close to a 20% increase.” Costs have fallen as well.

These improvements, however, pale in comparison to the reduced carbon footprint enabled by second-generation, or cellulosic ethanol. Cellulosic, refers to the woody parts of the plant, such as the leaves and stalks, which have little or no food value. It also includes wood chips, grasses, and forestry residue. This opens the door to far less energy-intensive plants that can grow without fertilizers or cultivation.

But while starch-based ethanol uses age-old distillation techniques, extracting sugars that are biochemically locked into cellulose, was not something that people knew how to do. So, cellulosic ethanol, which was the prize all along, for which the whole corn ethanol program was largely used to create an infrastructure, became a challenge, to the biotech industry.

According to Thomas Schrøder, Head of Biomass Conversion at Novozymes the results stack up something like this. If we look at carbon footprint, and give gasoline a reference rating of 100, we find that corn ethanol, depending on how it is produced, will have a footprint in the range of 50-70. Cellulosic ethanol, on the other hand, can be produced with a footprint ranging from 30 to zero.

Though the industry is in its infancy, the technology has arrived. DuPont recently opened the world’s largest cellulosic plant in Nevada, Iowa. It will produce 30 million gallons of ethanol from 375,000 metric tons (413 million short tons) of corn stover provided by local farmers. The company plans to license its technology in several countries including China. All told, there are currently two commercial plants in Brazil, three in the US, two in Europe, and one in China, representing a total investment of $2 billion. While the chemistry has been solved, says Schrøder, there are still issues associated with the mechanics of the process that are holding things back. In short, “how do you push through 30-50 metric tons (33-55 short tons) of biomass per hour without jamming up the works?”

Numerous biotech startups are building demonstration plants utilizing various approaches. Says Schrøder, “Most plants that are out there today are there because someone wanted to demonstrate the viability of the technology.”

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.eniday.com/en/technology_en/the-future-of-biofuels/

That's indeed a copy paste from the source :)

@terencehill888: It would have been better to write a single paragraph of your own and then give the link to the news. Believe me, people around here prefer that way.

Thanks for your consideration!

Not indicating that the content you copy/paste is not your original work could be seen as plagiarism.

Some tips to share content and add value:

Repeated plagiarized posts are considered spam. Spam is discouraged by the community, and may result in action from the cheetah bot.

Creative Commons: If you are posting content under a Creative Commons license, please attribute and link according to the specific license. If you are posting content under CC0 or Public Domain please consider noting that at the end of your post.

If you are actually the original author, please do reply to let us know!

Thank You!