Exploring the Forest of Dean: Clearwell Caves (part 2 of 2)

Hi and welcome back to part 2. Please see part 1 for the introduction and history of the place as well as the pictures of the entrance to Clearwell Caves:

https://steemit.com/beauty/@onesunbeingnow/exploring-the-forest-of-dean-clearwell-caves-part-1-of-2

Enjoy part 2!

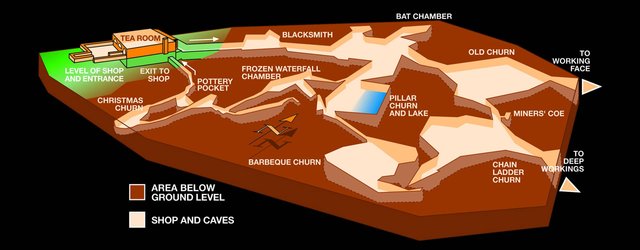

From the main building you begin your decent underground. The entrance marks the point where the early miners followed the iron ore underground once the surface ore had been depleted. They followed the ore in its irregular, winding course downwards through the Crease Limestone.

A 2-ft gauge railway also descends steeply into the mine and it is used to carry equipment in, and to bring minerals out of the mine.

The mine has always been predominately mined for ochres, as explored in part 1, with iron ore smelting being almost considered a secondary mineral.

Although no longer worked on a full-time basis, the mine does still produce a reasonable amount of ore for furnaces, for educational samples, and ochres for artist’s paints as mentioned previously.

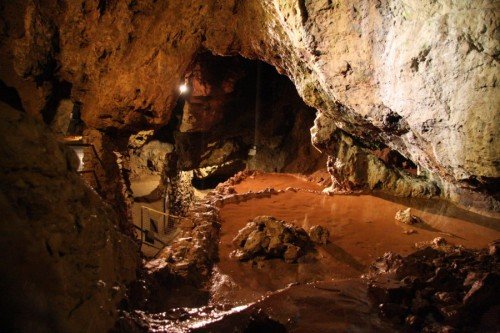

After the initial decent some 10-20 meters underground you come across this sink hole in the entrance to the first cavern along with the Bat Churn to the left.

Bat Churn:

Clearwell Caves is home to a variety of bats including the Greater Horseshoe, Natters and Long Eared Bats.

The Horseshoe is the most numerous bat here and also one of the rarest species in the country too, with only an estimated mere 2000. They often come here to hibernate during the winter, and their average colony is around 30 – 70.

The water pool depicted here was created by the miners to collect water for drinking. The water has such a good reputation that the people living above the mine would send their children down with buckets to collect the water.

Around the pool can be seen beautiful draperies of calcite, known as flowstone, formations which have grown since the full scale mining of this cavern ceased. Miner’s have striped caverns of their original iron ore and calcite formations decades ago.

Calcite grows at different rates depending temperature, air flow and concentration of calcium carbonate (calcite) in the water. At the temperature in this mine (10oC/50oF) and with the very high concentration of calcite in the water, it is estimated that flowstone grows at a rate of around 1 cm3 (0.06 in3) every 100 years.

Old Churn:

From the previous section a short decent leads into the Old Churn, an area where the vein of ore thickened out and partially filled a cavern (churn) in the surrounding limestone. Looking at the walls and ceiling you can see the peculiar character of this type of limestone – it has a box-like structure.

This rock, known as Crease Limestone’, has formed boxes which have partially filled with either black iron ore or white calcite crystals. The name ‘crease’ is a corruption of the Celtic name crys meaning ‘shirt’ or ‘jacket’, since the stone forms the ‘jacket’ that surrounds the ore.

All the largest churns of ore are found in this layer of rock.

Chain Ladder Churn:

This frightening sight is a 180 year old hand made chain ladder adjacent to the main similarly named ‘Chain Ladder Churn’. It used to be the only way in and out of the deeper levels of the mine.

Barbeque Churn

The next large cavern, 40 m x 20 m (130 ft x 65 ft), is called the Barbeque Churn. Originally a vast area of iron ore, it was later used for the dumping of rock from other parts of the mine. The original floor is some 5m (15 ft) bellow the present floor. The surface has now been levelled to make it suitable for functions. There is a candlelit, fancy-dress party held here each Halloween.

You leave Barbeque Churn through New Passage, driven in 1885 to allow ore remaining in the cave to be reworked.

Pillar Churn

Next is the Pillar Churn named after the large column of stone in the centre. The reservoir in this cavern controls the water that seeps through the shaft in the roof. The large flat roof is composed of a very solid rock known as Whitehead Limestone, referred to as the ‘lidestone’ because if forms the roof of most of the caverns throughout the entire cave system.

The miners would follow the ‘lead’ of iron ore running just under the ‘lidstone’ and when they came to a cavern would work the ore beneath it – a safe way of working.

Frozen Waterfall Churn

A left turn leads into a fine piece of flowstone known as the Frozen Waterfall. Normally calcite is pure white, but here iron-rich water has stained the flow to this attractive peach colour.

Pottery Churn

The next cavern is Pottery Churn where excavations revealed a wealth of bones, glass and pottery, some dating from the 15th century. This area had been open to the surface and was used by local inhabitants as a convenient rubbish dump. Some of the ‘rubbish’ also dates back to the 16th century too and selections of the findings can be found in the entrance museum mentioned in part 1.

Lastly we pass through a narrow winding tunnel up towards the mine buildings at the entrance, coming a full circle and completing our journey.

Thanks for viewing and I hope you enjoyed it, BYE!

For further study:

Baty, F.W., Forest of Dean

Bellow, J., A Week’s Holiday in the Forest of Dean

Dreghorn, William, Geology Explained in the Forest of Dean and the Wye Valley

Hart, Cyril, The Free Miners of the Royal Forest of Dean and the Hundred of St Briavels

Trotter, F.M., Geology of the Forest of Dean Coal and Iron Ore Field

I hope you enjoyed the article :) For more great content concerning trips I take, and health and wellbeing too, from nutrition to exercise, feel free to:

I have been on two cavern tours, Carter Caves / Mammoth Cave and I think these are great. Thanks for the post. This was very interesting and you have some great photos. You have a new follower..... :)

Sounds awesome, I'll have to look them up. I have also only been to two: the Big Pit National Coal Museum in Wales when I was young and Clearwell Caves. Glad you enjoyed the article :)