New Elevator technology is reshaping cities

The Finnish lift’s walls are bathed by a blue luminescence; music that is not quite jazz gently tootles within. The effect is comforting. But other things are odd. The lift’s dozen or so buttons seem numbered at random and, one would think, unfeasibly: 45, 105, 215, 270. At level 350 the doors hiss open on a dark and dirty cavern, silent save for the sound of dripping water.

Germany’s highest meeting room, 1,000km (600 miles) to the south-west of that strange Finnish lift, has its oddities, too. It looks out not at a central business district, but on the bucolic edge of the Black Forest. It sits atop a skyscraper which contains no offices but 12 lift shafts. In the lift by which you reach the penthouse an indicator tells you not just what floor you are headed for, but how fast you are getting there.

Thyssenkrupp, a German engineering conglomerate, and Kone, a Finnish liftmaker, are two of the world’s big four lift-engineering companies. As such, they need places to test new designs, new patterns of operation and new technologies. Kone does this in a mineshaft in Tytyri, about 50km west of Helsinki; if you take that glowing blue lift down to the dank cavern at level 350 — so called because it is 350 metres (1,150 feet) below the top of an adjacent shaft — and go through a steel door you will find yourself in the working mine which that other shaft serves.

Thyssenkrupp’s facility is more flashy; a slim, 246-metre-high concrete finger clad in an elegant barley-sugar twist of fabric. Inaugurated in October, it towers above the medieval town of Rottweil, hitherto best known for its beefy guard dogs. The town welcomed it with a two-day celebration; the view from the top — on a clear day you can see to the Alps — is expected to bring in an additional 50,000 tourists a year.

The technology being improved in these out-of-the-way places is essential to modern city life. Around 1bn people take one of the world’s 14m lifts every day; they take twice as many lift journeys in a day as people take flights in a year. Cities struggle on through bus and rail strikes; life without lifts, at least in central business districts, would more or less grind to a halt.

The lift is to the vertical what the car is to the horizontal: the defining means of transport. Like cars, modern lifts are creatures of the second industrial revolution of the late 19th century. Like cars, they have transformed the way that cities look, changing how and where people live and work. And today, like the cars that are lidar-sensing their way towards an autonomous future, lifts stand ready to change the city again.

Hoisting equipment of one sort or another has been in use for millennia. The Colosseum in Rome had 24 lifts powered by slaves. For centuries arrangements of pulleys and ropes were used in mines, factories and even occasionally to move people in palaces and private homes. Erhard Weigel, a 17th-century German mathematician, used a system of pulleys to transport himself around his seven-storey home in Jena. Louis XV installed a counterweight lift to his private chambers in Versailles in 1743.

The commanding heights

The modern lift was introduced to the public at New York’s Exhibition of the Industry of All Nations in May 1854 by Elisha Otis, whose name still adorns more elevators than any other. His patented innovation added to the basic box, rope and counterweight a spring-loaded ratchet which would stop the lift falling if the main cable snapped. In front of a large audience he ascended to a height of 15 metres before an assistant with an axe severed the cable. “All safe, gentlemen. All safe” he is said to have proclaimed after the safety catch tripped. He installed his first passenger lift in E.V. Haughwout and Company, a porcelain shop, three years later.

In extending the human world upwards, the lift overturned previous notions of prestige

It was not a success. Customers would not ride in the fearful new device, and Haughwout got rid of it in 1860. Otis’s eventual triumph had to wait for two other innovations: steel-frame construction, which allowed buildings to be taller, and electric motors, which allowed lifts to be faster.

Before the 1880s buildings had to support the load imposed by their upper floors with the walls of their lower ones. The taller the building, the thicker the lowest walls — and thus the less ground-floor space there was to rent. More than a dozen storeys was impractical.

Even at 12 storeys a lift comes in handy, and big new buildings in America started to boast them (in 1870 New York’s Equitable Life building became the first office to do so). But for the most part they used hydraulic lifts which pushed passengers up from below. These required a piston sunk down into the ground to a depth matching the height of the liftshaft — inconvenient, but not impossible for something under 20 storeys. And they were a lot faster than Otis’s steam-driven counterweight lifts.

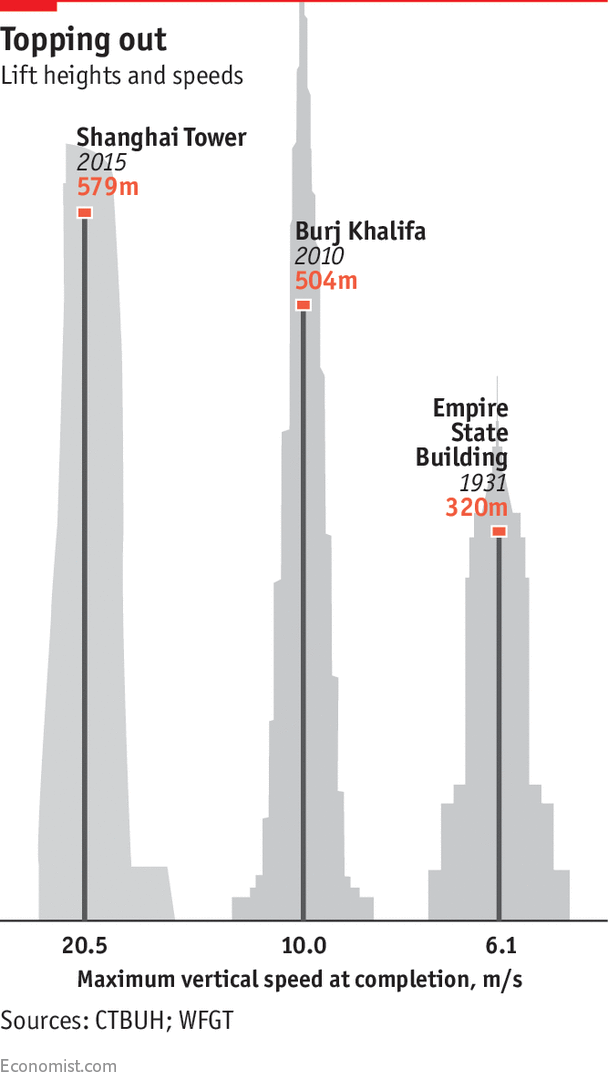

The electric motor changed that. Otis’s original steam-powered lift climbed at 0.2 meters per second (m/s). The electrified lifts in the first steel-framed building to top 50 floors, the 241-metre Woolworth Building, which opened in 1913, were more than ten times faster. Two decades later those in the 381-metre Empire State Building travelled at 6m/s, as fast as many modern lifts.

By this stage, America’s cities looked like nothing the world had ever seen before. Before the lift, buildings of more than six storeys were rare; roofscapes were low and even, broken occasionally by the bulk of citadels and places of worship. There are few such cityscapes left today. Paris has mostly succeeded in keeping its roofline even (despite a towering icon that depends on cunningly non-vertical lift technology). Kone’s 16th-floor boardroom, ironically, overlooks a Helsinki kept defiantly low-rise by strict planning laws. But most cities reach for the sky, sometimes dramatically — Dubai — sometimes in a higgle-piggle — São Paulo.

In extending the human world upwards, the lift overturned previous notions of prestige. Before the 20th century people prized proximity to the pavement. The first floor, above the hubbub of the street but conveniently accessed by a single flight of stairs, was the floor most sought after — the piano nobile or bel étage. Anything above the second floor was typically reserved for servants. In hotels and tenements, standards and prices fell with altitude. As Andreas Bernard points out in “Lifted: A Cultural History of the Elevator”, top floors were considered a public-health risk. The strain of tackling so many stairs, the difficulty of getting outside in the fresh air and the trapped heat of summer played a part in this. It may be no coincidence that the garrett was home to consumptive artists.

The lift not only made much higher floors possible, it gave them a new status and glamour. Rents began to rise, not fall, with height. The penthouse — a word that took its modern meaning in the 1920s — became a status symbol. From the Equitable Life Building onwards, top executives took to the top floors. Altitude was eminence, farsightedness, elevation — power.

Lifts also made the workplace more regular. Structures built around staircases had internal arrangements much less strict than today’s, with mezzanines and back-stairs that provided different points of access to the same floor. Lifts imposed a new simplicity. The lobby where lifts arrive and depart serves as a focus on each floor. Storeys are strictly and consistently set apart by number (with the occasional exception for triskaidekaphobes and their equivalents in other cultures). This repetitive stacking of space, some have argued, played a crucial role in formalising office plans and hierarchies. There is a reason why M.C. Escher never etched any delightfully paradoxical lift shafts.

By the 1970s lift engineering was a pretty mature industry, and started to consolidate and globalise. Kone and Thyssenkrupp, along with the Swiss firm Schindler, bought up rival firms to join Otis (now a division of United Technologies) as worldwide brands. Between them the big four now account for around two-thirds of the global market; Hitachi and Mitsubishi Electric of Japan take quite a lot of the rest. There is as yet no Chinese lift giant — perhaps because the industry relies as much on its ability to provide services on a global scale as on its mechanical engineering prowess. Half the big four’s annual revenues of $40bn (€36bn) come from that side of the business.

But if China is not a force in the industry, it has been a huge influence on it; the Chinese appetite for more, higher and faster lifts is like nothing seen since 1920s New York. In 2000 some 40,000 new lifts were installed in the country. By 2016 the number was 600,000 — almost three quarters of the 825,000 sold worldwide. China not only wanted more skyscrapers; it wanted taller ones. More than 100 buildings round the world are over 300 metres; almost all of them were built this century, and nearly half of them in China. The country is home to two-thirds of the 128 buildings over 200 metres completed in 2016. Other countries may content themselves with a few show-off pinnacles. China buys them by the dozen.

Such buildings exacerbate the constraints liftmakers and the architects they work with have always faced: time and space. Kheir Al-Kodmany at the University of Illinois has found that after 28 seconds waiting, would-be passengers start to get irritated. And while lifts make rentable floor space reachable, they attract no rent themselves. At the top of the tallest buildings (which are often tapered, both because of the wind and to reduce loading on the structure below) the lift shafts may take up 40% of the floor space. The fewer the shafts, the more lucrative the building.

Increasing speed, a focus of the Japanese lift manufacturers, saves some time. Lifts typically travel at around 8–9m/s. Mitsubishi’s lifts in the Shanghai Tower more than double that, reaching 20m/s (45 miles per hour). But though the users value speed, they have problems with the acceleration that provides it. Lifts accelerate at less than a tenth of the rate of an average car, because being pushed into the floor of a lift is a lot less comfortable than being pushed back in your seat. This means lifts can only reach their top speed on long uninterrupted runs. And even then, only on the upward leg; people are yet more sensitive to acceleration going down. Designers could get their lifts up to 20m/s just by letting them fall free for two seconds; but most customers wouldn’t thank them for it.

Henrik Ehrnrooth, the boss of Kone, thinks the quest for further speed is now pretty much played out. The time it takes for the doors to open and close, he says, has as big an influence on the total time it takes to get to your desk — the measure which matters most. Kone, and the rest of the big four, concentrate more on the hardware and algorithms needed to prevent unnecessary stopping and empty journeys, which cuts waiting times and reduces the number of shafts needed for a given building.

Liftmakers say that “Destination control”, in which the lift system tells the user which lift to use, rather than the user telling the lift where to go, reduces door-to-desk time by 30%. Pair it with double-decker lifts, which in very tall buildings usefully serve odd and even floors simultaneously, and you increase capacity even further. (Such lifts are also spectacular, at least they are if you are in the perspex-walled observation level halfway down one of Kone’s mineshaft testbeds watching them rush past like lorries.)

Alternatively, separate the top and the bottom deck and have two independent lifts in the same shaft. This allows an express lift serving a “sky lobby” on the 25th floor to run in the same shaft as the lift that offers a stopping service to the floors above. At least one company has attempted to put three lifts in a single shaft, but the challenges have so far proved insurmountable.

Really tall buildings pose problems of their own. Dubai’s Burj Khalifa, the tallest building in the world, has 163 floors and measures 830m to its tip. But to get to the top you must change at a sky lobby; the longest ride offered by any of its 57 lifts is just 504 metres. The limiting factor is the steel lift cable. Any longer and it gets so heavy that it might snap under it own weight.

UltraRope, developed by Kone, gets around this problem by using carbon fibre. When the Jeddah Tower in Saudi Arabia, the world’s first 1km building, opens in 2020 it will boast a 660-metre lift made possible by UltraRope; the company thinks doing a whole kilometre should be feasible, if anyone wants to.

UltraRope has other advantages. Tall buildings sway with the wind, an effect that Thyssenkrupp’s test tower replicates with 240 jiggle-able tonnes of concrete on the 21st floor. Steel amplifies the swing like a strummed guitar string, which can damage the shafts and the cables. UltraRope has a higher resonant frequency, making it less sensitive to such sway

The power of lateral thinking

A development being tested at Rottweil goes even further — doing away with the cable altogether. Thyssenkrupp, which also makes railway equipment, has harnessed high-speed rail technology to create Multi, a system held in place and accelerated by electromagnetic forces like those used for magnetic-levitation trains. This is not a new idea. One of the first people to look into it was a PhD student in Manchester in the 1970s, Haider al-Abadi, who is now prime minister of Iraq. But now it seems as if its time may have come.

By eliminating the cable, Multi aims to take away all limits on height other than those imposed by a building’s structure. The absence of cables will also allow lifts to move laterally, as well as vertically, making the whole system more like a railway. Lift shafts will be able to fork and rejoin to allow overtaking; descending lifts could sidestep ascending ones.

The first building to commission such lifts, Berlin’s East Side Tower, will not be able to use Multi until it has been certified by the authorities, probably around 2020. Nor can it make full use of the system’s potential; while Multi could have served its needs with just six shafts, the emergency services, less trusting of the new technology, have demanded two additional old-fashioned lifts so they can reach the upper floors if something goes wrong.

Further off, though, the possibilities have lift buffs giddy with excitement. Adrian Godwin, a consultant who has advised on some of the world’s tallest buildings, imagines systems like Multi making buildings of 250 storeys or more possible, with many more lift cabins circulating in cores smaller than those in use today. The number of cars in the system could be changed on the fly to reflect usage patterns, which will make things more energy-efficient.

Buildings could change shape, as well as size. Mr Godwin, along with Thomas Heatherwick, a noted British designer, has envisaged an office block that curves up elegantly from a large base using revolving lift cabins like those on a Ferris wheel. He also has a vision for a building shaped like a giant hoop; lifts freed from cables require no central core.

Perhaps most intriguing, new types of sideways-scooting lifts could link up whole clusters of buildings. Transport hubs could house lifts serving a range of local buildings, moving first horizontally, then vertically. Or the lifts could zip between their tops on skybridges. It took trees hundreds of million of years to evolve the structural systems and internal plumbing needed for wide-spreading boughs, thus making possible the wonderfully rich ecosystems of rainforest canopies. Lateral lifts could make canopy cities possible before Otis’s patent sees its bicentenary. Having let cities climb into the sky, the lift may now help them spread across it.

© 2018 The Economist. All right reserved.

Hi! I am a robot. I just upvoted you! I found similar content that readers might be interested in:

https://www.economist.com/news/christmas-specials/21732705-elevators-may-soon-go-sideways-well-up-new-lift-technology-reshaping-cities