Report on Acetonitrile Manufacturing Project Cost and Process

IMARC Group’s “Acetonitrile Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan report outlines every critical step involved in setting up an acetonitrile manufacturing plant successful unit — from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as manufacturing plant setup cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report: https://www.imarcgroup.com/acetonitrile-manufacturing-plant-project-report/requestsample

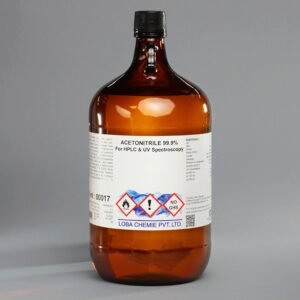

What is Acetonitrile?

Acetonitrile, also known as methyl cyanide, is a colorless, volatile, and flammable liquid with a faint ether-like odor. It is the simplest organic nitrile, with the chemical formula CH₃CN. Acetonitrile is widely used as a solvent in laboratories and industrial processes due to its excellent ability to dissolve a wide range of organic and inorganic compounds. It is particularly favored in high-performance liquid chromatography (HPLC) applications, where its low viscosity and UV transparency make it ideal for accurate analytical testing. Additionally, acetonitrile is used in the pharmaceutical industry for synthesizing active pharmaceutical ingredients (APIs) and in the manufacture of perfumes, batteries, and pesticides. It is a by-product of acrylonitrile production, which is mainly used in plastics and synthetic fibers. Due to its high polarity and low boiling point, acetonitrile offers efficient separation and easy recovery in chemical processes, making it a vital solvent in various industrial sectors.

Market Trend and Drivers of Acetonitrile:

The global acetonitrile market is being driven by increasing demand from pharmaceutical, chemical, and analytical industries. The rapid growth of pharmaceutical manufacturing—particularly in emerging economies—has significantly increased the need for acetonitrile as a solvent in drug synthesis and purification processes. Additionally, the expansion of the chemical industry, including agrochemical production for pesticides and herbicides, is boosting its consumption. Another major driver is the rise in demand for high-performance liquid chromatography (HPLC) applications across academic, research, and quality control labs, where acetonitrile plays a crucial role due to its high elution strength and purity. Furthermore, growing investment in energy storage technologies, especially lithium-ion batteries, has opened new avenues for acetonitrile use in battery electrolytes. Key Aspects to Setup an Acetonitrile Plant: How IMARC Can Help? IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research. Services: IMARC Group 134 N 4th St. Brooklyn, NY 11249, USA Email: [email protected] Tel No:(D) +91 120 433 0800 United States: +1-631-791-1145

Requirements to Setup a Facility:

Types of Costs to Setting up an Acetonitrile Factory:

Project Economics:

Key Questions Answered in the Report:

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=7335&flag=C

Contact Us: