The humanoid robot race

The humanoid robot race

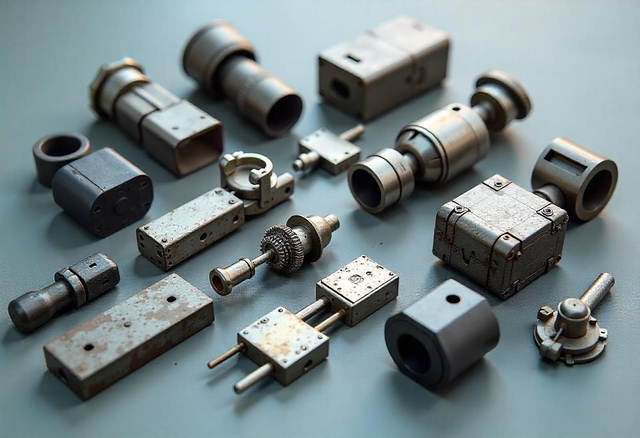

He decided on a screw

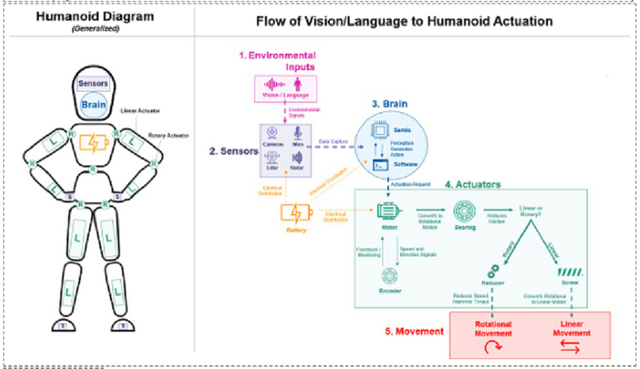

Modern machines like robots use it in all their parts.

China is positioned in the manufacture of these screws.

Follow my publications with the latest in artificial intelligence, robotics and technology.

If you like to read about science, health and how to improve your life with science, I invite you to go to the previous publications.

If you like to read about science, health and how to improve your life with science, I invite you to go to the previous publications.