What is Digital Fabrication? // Popular STEM

Greetings, digital travelers!

Today is a very special day: I'm finally starting this post, and thus this series, about Digital Fabrication! Naturally, this first post will serve as the Introduction to what this still unnamed series will be about, where it is based from, and covering what Digital Fabrication actually is.

As most of my creative productions recently, they're first done for my tasting and enjoyment. Of course I want to create content that adds vALuE, but the main goal is also for my own self: to rewrite my undergraduate thesis not only in English, but also with the goal of sharing it to real people (I hope :), and not having the weight of it being a crucial step to achieve my graduation. (cheers to that!!!)

Original Title:

Digital Fabrication and Mathematics

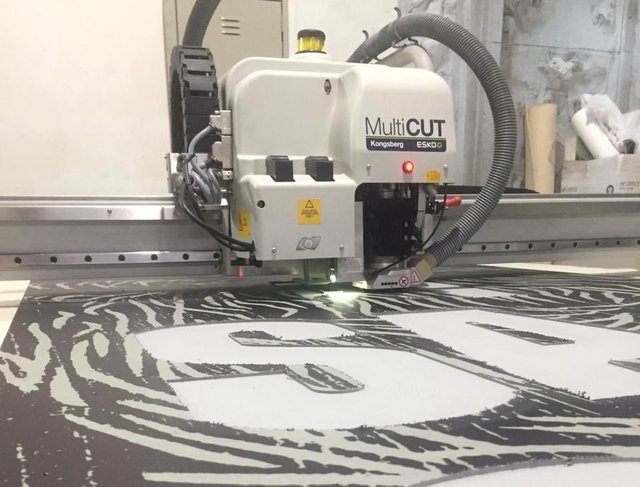

Image created in Canva Pro, using a photo of a CNC Laser machine working over a wood piece digitally printed over it. Source: author's collection.

Abstract

The objective of this thesis is to analyze the intrinsic relationship between Digital Fabrication and Mathematics, providing an overview of computer-aided fabrication processes and key related concepts, so that the understanding of the connection between this area and computational mathematics is facilitated. The use and diffusion of this knowledge in a FabLab at a Basic Education school in São Paulo, Brazil, is presented as an application of the technologies and content discussed throughout the text. The work is the result of more than a year of literature review added to the analysis of activities carried out over about a year and a half in a School FabLab, from the perspective of nearly ten years of the author's professional and personal experience in the field of Digital Fabrication.

Key-words: #DigitalFabrication, #ComputationalMathematics, #CNC, #CAD, #CAM, #BezierCurves, #MakerCulture, #STEAM.

Original Abstract and Dedication of my thesis, dated early 2023.

CNC Laser cut "insign" logo. Source: author's collection.

I dedicate this work to my father and to his father, my grandfather;

If today I walk my path with such pride,

it is because I have always felt the same pride for the path they walked before me.

Acknowledgements

And in the end, maybe there’s even a poetic closure to it, grandpa: CAD/CAM processes, that revolutionary thing of transferring information from one machine to another — somehow, we ended up becoming the receivers and interpreters of that output; because we’re constantly receiving so much digital information nowadays that we’ve had to learn, especially during this pandemic era, with telemedicine, with online meetings, how to handle this exchange too, right? It’s really interesting to look back at that foundation [of how all digital developments evolved].

See, that’s why you can’t work alone anymore. That no longer exists! For example, in engineering, you can do a lot, but if you don’t talk to the doctor, the doctor won’t even know that a certain thing is possible. That’s why you always need to have a connection between all the parts to know what to do. And this cooperation must exist. There can’t be, in Engineering or in Medicine today, this issue of competition. Competition leads nowhere. In truth, you need imagination and the will to make things happen.

And will only comes when there is unity.

If you don’t have unity, if you’re going to work alone, you won’t solve anything, alright?

Interview with my grandfather, the original Massola.

Conducted on September 18, 2022, at his home in São Paulo.

I'm sure this thesis (and this post :) would not exist if it weren't for the immense luck I have in being surrounded by so many incredible people who have always accompanied and supported me throughout my life. My family, my friends, my coworkers, my professors, my advisor. If you're reading this long text, which is perhaps the result of the greatest intellectual challenge I've ever imposed on myself, I am deeply grateful for your time. I hope that, if you crossed my path during this peculiar time in my life, I was able to show you how important it was not to face this challenge alone. And if you're just getting to know me now, or haven’t heard me talk about all this, I'm glad you've deemed this reading worthy of your time.

We can’t fulfill any dream alone. Unity, bonds, a shoulder to lean on when everything else feels unstable — these are essential for human development. At least, that's what seems to be the solution to many of the storms I've gone through in the singular twenty-five years I've experienced on this planet. I thank every person who contributed to the making of who I am today, because I never imagined facing the obstacles I faced — and I have no doubt they would have been impossible had I not known there was always someone there to catch me. Vai Corinthians!

Hey, dear Internet travelers, this paragraph is for you! I've used the help of my digital companion o3 to translate these words, and it moved me in a really unique way to reread these thoughts in the form of digital characters. I cannot recall the last time I did read it, but it continues to be the most truthful words. It's easy to get caught up in the chaos that is Existing; and that what makes it even more important to be grateful for every good being we come across in this Life.

Having said all that, I hope you believe me when I state here that I'm also really grateful to have the opportunity of being the author of these words you're reading right now. I hope you take something positive out of it, even if it's completely unrelated to Digital Fabrication. Take care of your own, and don't forget to take care of yourself, too!

Photo from December, 2021, of the FabLab I used to coordinate. Source: author's collection.

Glossary

- FD: Digital Fabrication, or Computer-Aided Fabrication

- CAD: Computer-Aided Design

- CAM: Computer-Aided Manufacturing

- NC: Numerical Control

- CNC: Computer Numerical Control

- FDM: Fused Deposition Modeling

- SLA: Stereolithography Apparatus

- SLS: Selective Laser Sintering

- PLA: Polylactic Acid

- ABS: Acrylonitrile Butadiene Styrene

- STEAM: Science, Technology, Engineering, Arts, and Mathematics

- AI: Artificial Intelligence

- IoT: Internet of Things

- STL: Standard Triangle Language

- TSP: Traveling Salesman Problem

What is Digital Fabrication?

Since our very first Homo ancestor struck a stone and turned it into a tool, human beings have relied on making things as a catalyst for development.

For centuries, manufacturing depended on people being actively involved in the production process, because the tools and machines required human operation—whether swinging a simple hammer or handling the dangerous blade of a circular saw. In the mid-20th century, after World War II, humanity took its first steps toward a sweeping transformation across many fields of knowledge and production: the Techno-Scientific-Informational Revolution, also known as the Third Industrial Revolution. During this period of unprecedented technological advances, one tool emerged that would become fundamental to the new manufacturing process: Numerical Control (NC).

Because it became necessary to control multiple machine axes and tools simultaneously, a special code was created to encode geometric information and numerical dimensions. It was christened—and is still generically called—G-CODE, with the letter “G” standing for Geometry. This method of producing manufacturing instructions via G-CODE was developed in the 1940s at MIT using punched tapes; with the advent of computing, it evolved into what we now call Computer Numerical Control (CNC). These systems are essential to the subject of this dissertation, since modern production equipment depends on them to carry out automated manufacturing.

What, then, defines Digital Fabrication (DF)?

According to researchers (CUTCHER-GERSHENFELD et al., 2018), DF differs from analog fabrication in that, whereas the latter uses tools and machines guided by the operator’s hands, in DF the guidance comes from a computer. The system knows exactly what the objects to be produced look like thanks to CAD software and algorithms that generate precise instructions for building the products. Thus, this new workflow embraces both CNC and emerging robotics-assisted production technologies, as well as digital-design and tool-path–generation processes that tell machinery exactly where to move.

The MultiCUT working head of a Konsberg ESKO Jobs CNC machine cutting an ACM panel at Insign. Source: author’s collection.

Among the advantages of DF, the most evident are higher accuracy and efficiency. A human being cannot achieve the same repeatable precision that computer-controlled machines can, and these machines typically finish jobs in significantly less time and at lower cost than traditional methods. One major drawback, however, is the highly specialized workforce required: neither machine operation nor digital-model creation is trivial. Once a skilled modeler is on board, DF makes prototyping far quicker and easier—alter the digital model, regenerate the instructions, and, provided the change is modest, production time remains roughly the same. Yet this standardized production time is a double-edged sword: while it enables far greater mass customization, it hampers large-scale manufacturing, since traditional methods like plastic injection molding become much faster once the mold is ready.

Many fields benefit from computer-aided manufacturing technologies. They are indispensable in product-design and prototyping (as noted above) and are used across industries from aerospace and automotive to medical and dental. DF processes are also widely applied in modern architecture, both during design and in fabricating custom components. Artists and designers have likewise embraced these technologies, realizing one-of-a-kind, intricate works—from sculptures and jewelry to fabrics made entirely of plastic. Finally, one of the most compelling applications—and the one I have chosen to illustrate in this paper—is DF in K-12 education. The number of maker spaces in schools has risen sharply in recent years, and, when implemented professionally and thoughtfully, they yield enormous pedagogical gains on many fronts.

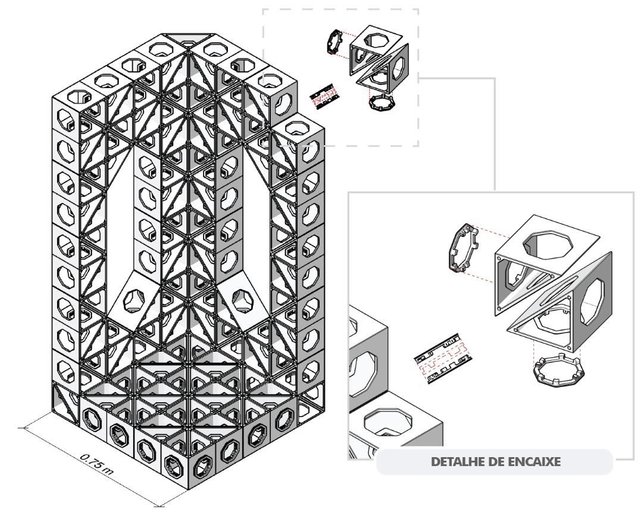

Considering digital-fabrication technologies at the forefront of architectural production, one can say their adoption is limited by the architect’s difficulty in interacting with the process. On the other hand, this step forward is essential for changing existing manufacturing models and spurs new cultural, social, and technological developments. (MATIAS, 2021)

In short, DF has revolutionized our relationship with production processes, from design through manufacturing. It is a technological field that has advanced rapidly in recent decades and is poised only to improve as swift progress in Artificial Intelligence (AI) and the Internet of Things (IoT) coincides with falling costs. We can speculate that, in the near future, these developments will bring even greater precision, efficiency, and customization, leading to ever broader and more democratic use of these technologies.

Tie-beam model for a wall end, assembled with modular blocks conceived and produced by Maurício Matias — an example of DF applied to architectural building components. Source: “Digital Fabrication: Design and Development of a CNC Device for Producing Building Elements,” MATIAS, Maurício.

Final Thoughts

Okay, I have to admit I thought this process would be quicker given that I already had my thesis ready, but that's the way creative processes are. I probably missed some misspelled words, as I did in the last few posts, but that's also part of creating: imperfection. If there's one thing I learned creating multiple projects with Digital Fabrication throughout these years, is that nothing is ever gonna be just like you envisioned; and that's okay! We need to learn to ask the whys and hows when unexpected things happen, otherwise we'll just feel like we're failing at each step. And I learned it a lot by working day after day with the most amazing children at my former Lab. The excitement was sometimes overwhelming, and so was their boredom; while for the first case I had to learn to be the adult one and keep things calm, for the latter I learned about truly being an educator.

I'm really happy to be concluding this still-without-a-name series (yes, this is a hint for you that you can suggest names in the comments!), and I really do hope you liked it. Any feedback, suggestions or questions you have about topics related to Digital Fabrication, feel free to leave in the comments! Interaction is the key to these complicated gates of digital relationships.

You know what else can help us to create valuable interactions, and also solve the long-lasting issue in our platform of the lack of #lifetime-rewards? The great project @thoth.test , created by our digital companion @remlaps ! If you're curious, you can learn more about it in its git. In full disclosure, I am currently supporting the project via a humble SP delegation, and also by setting 5% of the rewards of my recent posts to the account. I've also set 25% of the rewards to @null , in order to fight inflation in our network. #burnsteem25

“Digital Fabrication machines of the next decade”, prompt used to generate the Figure above, using the tool Stable Diffusion Online. Access on the 14th of February of 2023. URL: https://stablediffusionweb.com/

If you've got to here, thank you! My gift for you is this singular image Stable Diffusion generated for me almost two and a half years ago. Maybe I could try the same prompt in GPT o3 today, on the 31st of August of 2025:

Interesting to note the robotic arm centering the image, right? But yeah, to be honest, I still prefer my purplish Stable Diffusion generation from my thesis.

I hope you have a great one over there, and maybe today is the day you give yourself a chance to let the artist within you to flourish (:

I'll use this comment to register other images generated with this same prompt, since I was curious of how it would differ after almost two and a half years from the one I generated for my thesis.

First off, https://stablediffusionweb.com/ has improved its ux a lot, but with that comes the so fun limited credits for a free account. I'll check if I can generate images with an earlier model via some option.

Prompt in English:

(I see some resemblance to my original purple image with the cables, huh?)

chriddi, moecki and/or the-gorilla

I forgot to credit the great tool @steempro.com , that really helped me to develop this article using my mobile phone. Today has been a really busy day, and I even though I had already sent the parts of my thesis to GPT to translate and saved the images on my Telegram, I still had to build the post entirely here: and it was great! I truly liked using it. Cheers!