SLC | S21W1 | Costos para emprendedores - Introducción al costo.

Hello my steemian friends,

This is my participation in the Teaching contest” SLC | S21W1 | Costos para emprendedores - Introducción al costo. Organised by teaching Team @yolvijrm in #costs-s21w1

What is cost and what is its importance for entrepreneurs?

All the money spent in the manufacture of any product is called the cost of that product. Actually, we should make a detailed plan for the manufactur of any product and then estimate the cost incurred on it in detail.

First of all, we should calculate the interest on our investment. Suppose I start a medicine manufacturing business, then I will have to add a building as per the norms, necessary equipment for medicine manufacturing, electricity supply, hiring technically trained people, unskilled labour, packing material, raw material, moulds, license expenses, official expenses, marketing expenses, legal advice expenses, transportation, income tax, trade tax, manufacturing duty, and other unseen incidental expenses .

And then after this we will have to fix the price of our product in such a way that all our production costs are met out by its sale and we also get profit. Incidental expenses sometimes play a very important role in spoiling our such estimates. But no sensible person ignores them.

Establish the difference between cost and expense by giving an example through a real case.

Whatever cost I have mentioned above includes both actual cost and expense, like raw, mall, labels, vials, equipment, packing material etc. are the price of the product.

But wages of workers, rent of building, electricity and water charges, transportation expenses, manufacturing duty, taxes, traveling expenses, remuneration fee of partners/directors/propriter , incidental expenses like breakage and repair of machines, travel bills of employees, publicity, legal fees, bank interest, bank charges etc. are included in expenses.

What are the benefits of good costing?

I think we do not need to do cost cutting in any of our expenses to make a good product, rather to make a good product we have to take full care of quality and customer requirement, and market requirements.

We have to focus on new research and make the best combination for the treatment of our patients. We also have to keep in mind the rules and announcements issued by the drug administration officials from time to time.

We have to keep an eye on the daily amendments of the British Pharmacopoeia and the US Pharmacopoeia, and on this basis we have to introduce only the latest formulations in the market. In the drug manufacturing business, two types of medicines are allowed to be made, one type of medicines are called generic drugs and the other are patented medicines.

The manufacturer cannot mark his proper name on the generic drug, rather it is sold by the name of the salt of the medicine. The price of which is unexpectedly low and poor patients get its benefit.

But many manufacturers manufacture both types of medicines and by doing bulk manufacturing, the cost of the medicine remains very low and even though there is no profit in making this generic, the manufacturing cost is covered.

And along with that, the manufacturer compensates for this by increasing the prices of the products with patent names. Governments also provide a lot of subsidy to the generic drug manufacturers. Which affects the entire manufacturing cost.

How do you determine the cost of your enterprise? If you are not an entrepreneur, how will you do it?

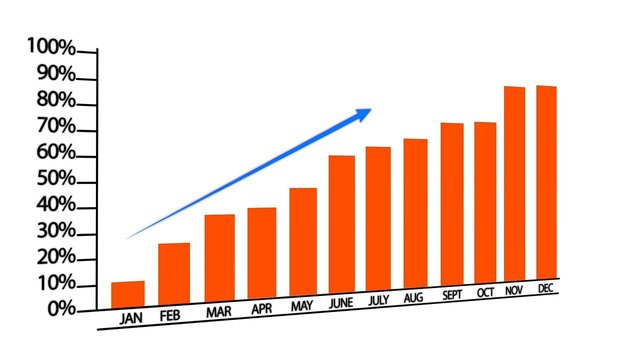

It is simple, I have to make a strategy that how many medicines I have to make and sell in the whole month, because the expenses of setting up the factory are fixed assets, which are incurred only once, if we talk about maintenance, then they are also ignored for once.

Now by manufacturing the medicines as per my plan, I get to know how much we have to spend on the manufacturing of these medicines, this makes it easier for us to decide its price. But the most important thing is that we have to focus more on marketing than manufacturing, because if the sales are not done at the pace of our manufacturing, then the company may suffer a loss.

Now we manufacture medicines as per the requirement of the market and our profits and sell them in the market. Quality and promotion play a very important role in this. In the case of medicines, there is a huge difference between the price of raw material and the finished medicine, sometimes this difference is 10 to 20 times. That is why if we meet our sales targets while keeping quality in mind, then there is no reason for loss. I

n my medicine manufacturing sector, it is not appropriate to fix any price for any medicine. Its size plays a role in setting up this entire enterprise, if we set up only tablet section, or syrup section, or capsule section, or dry syrup section, or injection section, or ophthalmic section, or glucose slin water section or all together then the size of cost also becomes different.

I also want to invite here

@patjewell, @paholags, @malikusman1, @starrchris, @drhira,

Thanks for reading my post, I pray to God for the progress and happy future of all Steemians.

Sur-riti❤️

Twitter post

https://x.com/Ku55260991Ashok/status/1851952876836331536

Greetings @sur-riti

1.- You have shared the concept and importance of cost determination. It sounds interesting to generate a cost report to start a drug manufacturing business, there are many elements that must be taken into account, which must be adequately covered to make an effective price calculation.

2.- You have mentioned the difference between costs and expenses. Among the expenses, basic services are presented; because, although they influence production, they are also used in the rest of the business environment. There is an item that has had a difference of point of view, which is the disbursement for training courses, in most cases it is considered costs.

3.- You have shared the benefits generated by good cost determination based on quality levels on a product, in the area of medicine, it has been necessary to adjust costs based on quality, to benefit the population most vulnerable.

4.- You have shared the details that you keep in mind to determine the costs in a medicine manufacturing business. The market study is carried out before generating disbursements to start a production process, although in the area of medicine, it is difficult for there to be a lack of interest on the part of the population to obtain them, so it must be concentrated on the production and final product (different medications in this case).

Thanks for joining the contest

Hello Sir, @adaljose

You have assessed my post very accurately, you have said at one place that disbursement should also be considered as a part of cost, I do not deny it at all. I remember very well that when we appointed sales representatives in our sales team to launch our products in the market, we spent a good amount of money in their selection, training and providing them with catalogues of medicines and visual aids etc. But the only reason for avoiding mentioning it in detail is that if I sit down to write every detail of the entire project, then I will have to write many pages. Yes, I have mentioned the payment of travel bills of my employees in the same context in my answer to question 2. I hope you will kindly agree with me.

I bow to your knowledge and your assessment. Thanks a lot.

Its development is good, however, it does not share a numerical example, I know very well that the case it covered generates a lot of information, but perhaps it was not appropriate for this opportunity, since it was something complex to detail.

TEAM 1

Congratulations! Your comment has been upvoted through @steemcurator03. Good post here should be..Thank you for support @jyoti-thelight